STM32控制BLDC-如何让电机转起来

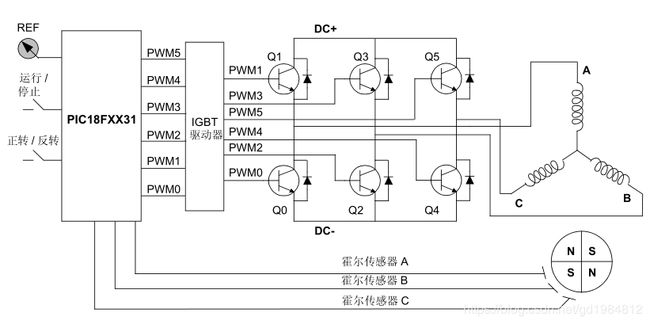

无刷直流电机比较流行,很多电机内部加入霍尔元件,通过霍尔元件可以知道电机转子的位置,根据这个位置给电机相线供电,这样电机就转起来了。框图如下所示

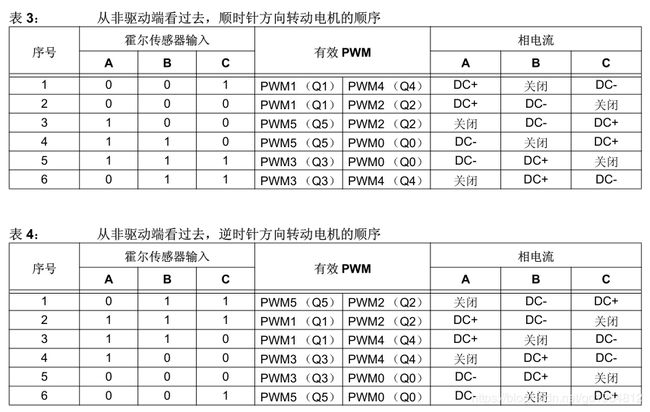

霍尔元件输出与相线输入电压的关系可以让BLDC电机厂家提供,一般都提供这个对应关系表,如下图所示

有了上面这些足可以让我们设计电路编写程序让电机转起来!

有上面的框图可以看出,3相电机的驱动需要六个mos管,一般用的是NMOS,大功率的NMOS比较便宜。大功率MOS管有较大的结电容,控制电压也高些,无法用单片机直接驱动,所以需要驱动电路。驱动芯片组成的驱动电路比较简单,常见的有IR2110S,我这里用IR2110S设计了MOS驱动电路,如下图所示,其中C24和D5是自举电路,为了控制Q3抬高电压。

3片IR2110S驱动6个NMOS,如下图

霍尔元件供电是5V,他的输出一般也是5V,可以分压后给单片机用。

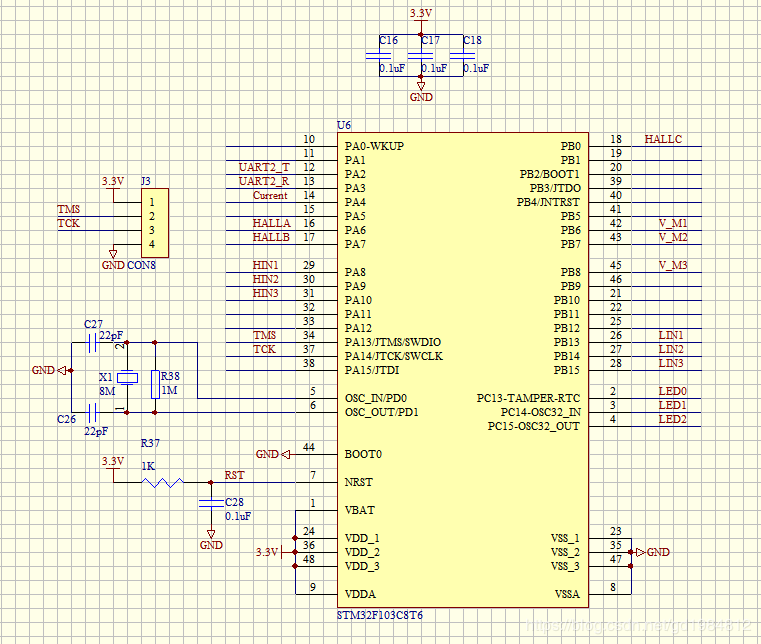

单片机用流行STM32,他有高级定时器T1,T8,可以输出3对互补的PWM波,还有刹车信号输入,这些特性对于电机的可控制非常合适。电路如下图所示

BLDC电机控制用到单片机定时器及IO中断,初始化部分如下

void TIM_Config(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

TIM_TimeBaseInitTypeDef TIM_TimeBaseInitStruct;

TIM_OCInitTypeDef TIM_OCInitStructure;

TIM_BDTRInitTypeDef TIM_BDTRInitStructure;

EXTI_InitTypeDef EXTI_InitStructure;//

NVIC_InitTypeDef NVIC_InitStructure;

TIM_ICInitTypeDef TIM_ICInitStructure;

// ¿ªÆô¶¨Ê±Æ÷ʱÖÓ,¼´ÄÚ²¿Ê±ÖÓCK_INT=72M

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA | RCC_APB2Periph_GPIOB | RCC_APB2Periph_TIM1, ENABLE);

RCC_APB2PeriphClockCmd(RCC_APB2Periph_AFIO,ENABLE);

// Êä³ö±È½ÏͨµÀ1 GPIO ³õʼ»¯

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_8 | GPIO_Pin_9 | GPIO_Pin_10 ;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_13 | GPIO_Pin_14 | GPIO_Pin_15;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOB, &GPIO_InitStructure);

//»ô¶ûÊäÈë

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_6 | GPIO_Pin_7 ;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_IPU;

GPIO_Init(GPIOA, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_0 ;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_IPU;

GPIO_Init(GPIOB, &GPIO_InitStructure);

GPIO_EXTILineConfig(GPIO_PortSourceGPIOB,GPIO_PinSource0);

EXTI_InitStructure.EXTI_Line=EXTI_Line0;

EXTI_InitStructure.EXTI_Mode = EXTI_Mode_Interrupt;

EXTI_InitStructure.EXTI_Trigger = EXTI_Trigger_Rising_Falling;

EXTI_InitStructure.EXTI_LineCmd = ENABLE;

EXTI_Init(&EXTI_InitStructure);

NVIC_InitStructure.NVIC_IRQChannel = EXTI0_IRQn;

NVIC_InitStructure.NVIC_IRQChannelPreemptionPriority = 0x01;

NVIC_InitStructure.NVIC_IRQChannelSubPriority = 0x01;

NVIC_InitStructure.NVIC_IRQChannelCmd = ENABLE;

NVIC_Init(&NVIC_InitStructure);

GPIO_EXTILineConfig(GPIO_PortSourceGPIOA,GPIO_PinSource6);

EXTI_InitStructure.EXTI_Line= EXTI_Line6;

EXTI_InitStructure.EXTI_Mode = EXTI_Mode_Interrupt;

EXTI_InitStructure.EXTI_Trigger = EXTI_Trigger_Rising_Falling;

EXTI_InitStructure.EXTI_LineCmd = ENABLE;

EXTI_Init(&EXTI_InitStructure);

NVIC_InitStructure.NVIC_IRQChannel = EXTI9_5_IRQn;

NVIC_InitStructure.NVIC_IRQChannelPreemptionPriority = 0x01;

NVIC_InitStructure.NVIC_IRQChannelSubPriority = 0x02;

NVIC_InitStructure.NVIC_IRQChannelCmd = ENABLE;

NVIC_Init(&NVIC_InitStructure);

GPIO_EXTILineConfig(GPIO_PortSourceGPIOA,GPIO_PinSource7);

EXTI_InitStructure.EXTI_Line= EXTI_Line7;

EXTI_InitStructure.EXTI_Mode = EXTI_Mode_Interrupt;

EXTI_InitStructure.EXTI_Trigger = EXTI_Trigger_Rising_Falling;

EXTI_InitStructure.EXTI_LineCmd = ENABLE;

EXTI_Init(&EXTI_InitStructure);

NVIC_InitStructure.NVIC_IRQChannel = EXTI9_5_IRQn;

NVIC_InitStructure.NVIC_IRQChannelPreemptionPriority = 0x01;

NVIC_InitStructure.NVIC_IRQChannelSubPriority = 0x03;

NVIC_InitStructure.NVIC_IRQChannelCmd = ENABLE;

NVIC_Init(&NVIC_InitStructure);

TIM_DeInit(TIM1); //½«ÍâÉèTIM1¼Ä´æÆ÷ÖØÉèΪȱʡֵ

TIM_TimeBaseInitStruct.TIM_ClockDivision = TIM_CKD_DIV1 ;

TIM_TimeBaseInitStruct.TIM_CounterMode = TIM_CounterMode_Up ;

TIM_TimeBaseInitStruct.TIM_Period = 1000 ;

TIM_TimeBaseInitStruct.TIM_Prescaler = 3 ;

TIM_TimeBaseInitStruct.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(TIM1, &TIM_TimeBaseInitStruct ) ;

/* ¶¨Ê±Æ÷Êä³öͨµÀ1ģʽÅäÖà */

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;

TIM_OCInitStructure.TIM_OutputNState = TIM_OutputNState_Enable;

TIM_OCInitStructure.TIM_Pulse = 1000;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High;

TIM_OCInitStructure.TIM_OCNPolarity= TIM_OCNPolarity_High;

TIM_OCInitStructure.TIM_OCIdleState = TIM_OCIdleState_Set;

TIM_OCInitStructure.TIM_OCNIdleState = TIM_OCNIdleState_Set;

TIM_OC1Init(TIM1, &TIM_OCInitStructure);

TIM_OC2Init(TIM1, &TIM_OCInitStructure);

TIM_OC3Init(TIM1, &TIM_OCInitStructure);

/* Automatic Output enable, Break, dead time and lock configuration*/

TIM_BDTRInitStructure.TIM_OSSRState = TIM_OSSRState_Enable;

TIM_BDTRInitStructure.TIM_OSSIState = TIM_OSSIState_Enable;

TIM_BDTRInitStructure.TIM_LOCKLevel = TIM_LOCKLevel_OFF;

TIM_BDTRInitStructure.TIM_DeadTime = 1;

TIM_BDTRInitStructure.TIM_Break = TIM_Break_Disable;

TIM_BDTRInitStructure.TIM_BreakPolarity = TIM_BreakPolarity_High;

TIM_BDTRInitStructure.TIM_AutomaticOutput = TIM_AutomaticOutput_Enable;

TIM_BDTRConfig(TIM1, &TIM_BDTRInitStructure);

TIM_OC1PreloadConfig(TIM1,TIM_OCPreload_Enable);

TIM_OC2PreloadConfig(TIM1,TIM_OCPreload_Enable);

TIM_OC3PreloadConfig(TIM1,TIM_OCPreload_Enable);

TIM_ARRPreloadConfig(TIM1, ENABLE);

TIM_Cmd(TIM1, ENABLE);

TIM_CtrlPWMOutputs(TIM1, ENABLE);

TIM_CCxCmd(TIM1,TIM_Channel_1,TIM_CCx_Enable);

TIM_CCxNCmd(TIM1,TIM_Channel_1,TIM_CCxN_Enable);

TIM_CCxCmd(TIM1,TIM_Channel_2,TIM_CCx_Enable);

TIM_CCxNCmd(TIM1,TIM_Channel_2,TIM_CCxN_Enable);

TIM_CCxCmd(TIM1,TIM_Channel_3,TIM_CCx_Enable);

TIM_CCxNCmd(TIM1,TIM_Channel_3,TIM_CCxN_Enable);

}让电机转起来需要知道电机转子的位置,根据霍尔相位对应表驱动电机相线,程序里用中断获取霍尔电平的变化。

void EXTI0_IRQHandler(void)

{

int i,j;

if(EXTI_GetITStatus(EXTI_Line0)!=RESET)

{

EXTI_ClearITPendingBit(EXTI_Line0);

step=((GPIOA->IDR & GPIO_Pin_6)>>6)+((GPIOA->IDR & GPIO_Pin_7)>>6)+((GPIOB->IDR & GPIO_Pin_0)<<2);

if(start==1)

{

TIM1->CCER=PHASE_CHANGE[step];

int_count1++;

}

}

}

void EXTI9_5_IRQHandler(void)

{

int i,j;

if(EXTI_GetITStatus(EXTI_Line6)!=RESET)

{

EXTI_ClearITPendingBit(EXTI_Line6);

step=((GPIOA->IDR & GPIO_Pin_6)>>6)+((GPIOA->IDR & GPIO_Pin_7)>>6)+((GPIOB->IDR & GPIO_Pin_0)<<2);

if(start==1)

{

TIM1->CCER=PHASE_CHANGE[step];

int_count2++;

}

}

if(EXTI_GetITStatus(EXTI_Line7)!=RESET)

{

EXTI_ClearITPendingBit(EXTI_Line7);

step=((GPIOA->IDR & GPIO_Pin_6)>>6)+((GPIOA->IDR & GPIO_Pin_7)>>6)+((GPIOB->IDR & GPIO_Pin_0)<<2);

if(start==1)

{

TIM1->CCER=PHASE_CHANGE[step];

int_count3++;

}

}

}

检测到变化后改变定时器输出,从而使电机相线得到驱动,我在程序里做好了数组,把得到了位置通过数组给定时器CCER寄存器,这样电机就转起来了

int PHASE_CHANGE[7]={0x0000,0x0104,0x0041,0x0140,0x0410,0x0014,0x0401};这是霍尔输出与PWM输出波形的截图

这是定时器3对PWM的输出截图

这是电机和电路板