压电式加速度传感器动态特性

压电式加速度传感器动态特性

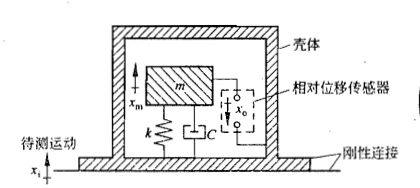

压电式加速度传感器工作原理如下图所示:

将加速度传感器壳体位移设为 x 1 ( t ) x_1(t) x1(t),质块m运动设为 x 0 ( t ) x_0(t) x0(t),

质块相对于壳体的运动设为 x 01 ( t ) x_{01}(t) x01(t)。

压电式加速度传感器的数学模型

依照传感器的力学模型,有达朗贝尔原理可以有以下运动微分方程:

m d 2 x 0 d t 2 + c ( d x 0 d t − d x 1 d t ) + k ( x 0 ( t ) − x 1 ( t ) ) m\frac{d^2x_0}{dt^2}+c(\frac{dx_0}{dt}-\frac{dx_1}{dt})+k(x_0(t)-x_1(t)) mdt2d2x0+c(dtdx0−dtdx1)+k(x0(t)−x1(t))

压电式传感器系统输入为壳体运动 x 1 ( t ) x_1(t) x1(t),输出为质块m与壳体的相对运动 x 01 ( t ) x_{01}(t) x01(t),此二者的关系为:

x 01 ( t ) = x 0 ( t ) − x 1 ( t ) x_{01}(t)=x_0(t)-x_1(t) x01(t)=x0(t)−x1(t)

于是运动微分方程可以写为:

m d 2 x 0 1 d t 2 + c ( d x 01 d t ) + k x 01 ( t ) = − m d 2 x 1 d t 2 m\frac{d^2x_01}{dt^2}+c(\frac{dx_{01}}{dt})+kx_{01}(t)=-m\frac{d^2x_1}{dt^2} mdt2d2x01+c(dtdx01)+kx01(t)=−mdt2d2x1

设被测振动为为谐波振动,即有:

x 1 ( t ) = X 1 s i n ( ω t ) x_1(t)=X_1sin({\omega}t) x1(t)=X1sin(ωt)

于是运动微分方程:

m d 2 x 0 1 d t 2 + c ( d x 01 d t ) + k x 01 ( t ) = m X 1 ω 2 s i n ( ω t ) m\frac{d^2x_01}{dt^2}+c(\frac{dx_{01}}{dt})+kx_{01}(t)=mX_1{\omega}^2sin({\omega}t) mdt2d2x01+c(dtdx01)+kx01(t)=mX1ω2sin(ωt)

将其写为一般形式为:

d 2 x 0 1 d t 2 + 2 ξ ω n ( d x 01 d t ) + ω 2 x 01 ( t ) = X 1 ω 2 s i n ( ω t ) \frac{d^2x_01}{dt^2}+2{\xi}{\omega_n}(\frac{dx_{01}}{dt})+{\omega^2}x_{01}(t)=X_1{\omega}^2sin({\omega}t) dt2d2x01+2ξωn(dtdx01)+ω2x01(t)=X1ω2sin(ωt)

次微分方程的解由通解和特解两部分组成,其中通解反映此系统的固有特性,特解反映其动态特性;

由于激励为一个正弦信号,因此其响应也为同频率的正弦信号,设其响应为:

x 01 ( t ) = X 01 sin ( ω t + ϕ ) x_{01}(t)=X_{01}\sin({\omega}t+\phi) x01(t)=X01sin(ωt+ϕ)

于是有:

d x 01 d t = ω X 01 cos ( ω t + ϕ ) = ω X 01 sin ( ω t + ϕ + π 2 ) d x 01 2 d t 2 = − ω 2 X 01 sin ( ω t + ϕ ) = d x 01 2 d t 2 = ω 2 X 01 sin ( ω t + ϕ + π ) \frac{dx_{01}}{dt}={\omega}X_{01}\cos{({\omega}t+\phi)}={\omega}X_{01}\sin{({\omega}t+\phi+\frac{\pi}{2})}\\ \frac{dx^2_{01}}{dt^2}=-{\omega}^2X_{01}\sin{({\omega}t+\phi)}=\frac{dx^2_{01}}{dt^2}={\omega}^2X_{01}\sin{({\omega}t+\phi+\pi)} dtdx01=ωX01cos(ωt+ϕ)=ωX01sin(ωt+ϕ+2π)dt2dx012=−ω2X01sin(ωt+ϕ)=dt2dx012=ω2X01sin(ωt+ϕ+π)

按照旋转向量计算,最终得出其响应为:

A x ( ω ) = X 0 1 X 1 = ( ω / ω n ) [ 1 − ( ω / ω n ) 2 ] 2 + [ 2 ξ ( ω / ω n ) ] 2 ϕ ( ω ) = arctan ( 2 ξ ( ω / ω n ) 1 − ( ω / ω n ) 2 ) A_x(\omega)=\frac{X_01}{X_1}=\frac{({\omega}/{\omega}_n)}{\sqrt{[1-({\omega}/{\omega}_n)^2]^2+[2{\xi}({\omega}/{\omega}_n)]^2}}\\ {\phi}(\omega)=\arctan(\frac{2{\xi}({\omega}/{\omega}_n)}{1-({\omega}/{\omega}_n)^2}) Ax(ω)=X1X01=[1−(ω/ωn)2]2+[2ξ(ω/ωn)]2(ω/ωn)ϕ(ω)=arctan(1−(ω/ωn)22ξ(ω/ωn))

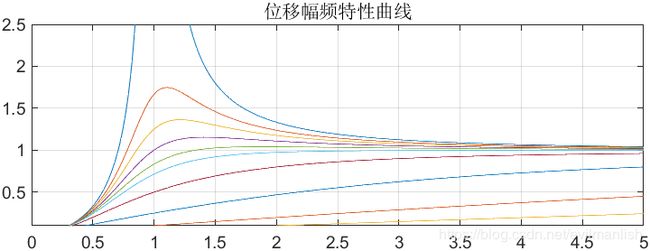

MATALB绘制幅频特性曲线与相频特性曲线

由于MATLAB中反三角函数 a r c t a n arctan arctan输出默认为 [ − π / 2 , π / 2 ] [-\pi/2,\pi/2] [−π/2,π/2],因此需要将自定义函数,将其输出改为 [ − π / 2 , π / 2 ] [-\pi/2,\pi/2] [−π/2,π/2],代码为:

function angle = atandpi(x)

%将atand输出更改为0-pi

% 此处显示详细说明

y=atand(x);

L=length(y);

for i=1:L

if y(i)<0

y(i)=y(i)+180;

end

end

angle=y;

end

然后绘制幅频与相频特性曲线,代码为:

%压电式振动传感器的动态特性

clear;

clc;

r=0:0.01:10;

xi=[0,0.3,0.4,0.5,0.6,0.7,1,2,5,10];

%位移幅频特性

Ax1=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(1))*(r)).^2));

Ax2=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(2))*(r)).^2));

Ax3=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(3))*(r)).^2));

Ax4=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(4))*(r)).^2));

Ax5=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(5))*(r)).^2));

Ax6=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(6))*(r)).^2));

Ax7=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(7))*(r)).^2));

Ax8=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(8))*(r)).^2));

Ax9=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(9))*(r)).^2));

Ax10=(r.^2)./sqrt(((1-(r.^2)).^2)+((2*(xi(10))*(r)).^2));

subplot(2,1,1);

plot(r,Ax1,r,Ax2,r,Ax3,r,Ax4,r,Ax5,r,Ax6,r,Ax7,r,Ax8,r,Ax9,r,Ax10);

title('位移幅频特性曲线');

xlim([0 5]);

ylim([0.1 2.5]);

grid on;

%相频特性曲线

phi1=atandpi((2*xi(1)*r)./(1-(r.^2)));

phi2=atandpi((2*xi(2)*r)./(1-(r.^2)));

phi3=atandpi((2*xi(3)*r)./(1-(r.^2)));

phi4=atandpi((2*xi(4)*r)./(1-(r.^2)));

phi5=atandpi((2*xi(5)*r)./(1-(r.^2)));

phi6=atandpi((2*xi(6)*r)./(1-(r.^2)));

phi7=atandpi((2*xi(7)*r)./(1-(r.^2)));

phi8=atandpi((2*xi(8)*r)./(1-(r.^2)));

phi9=atandpi((2*xi(9)*r)./(1-(r.^2)));

phi10=atandpi((2*xi(10)*r)./(1-(r.^2)));

subplot(2,1,2);

plot(r,phi1,r,phi2,r,phi3,r,phi4,r,phi5,r,phi6,r,phi7,r,phi8,r,phi9,r,phi10);

title('相频特性曲线');

xlim([0 3])

grid on;

%速度幅频特性