这个实验是一个老外在2006年做的。

作者针对抛光和喷漆(黑)对散热片温度的影响作了很多探讨,也很有意思,下面是我的笔记:

实验条件如下:

6063铝棒2根。直径0.75in。

一个半抛光,一个半抛光后喷黑色涂料。长度一致都为1.735in。

每个铝棒上挖了一个深度为0.375in的小洞,放热电偶。

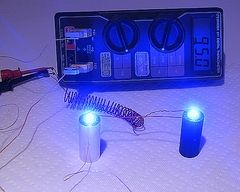

2个灯珠串联,1000mA电流流过。

其中喷黑的LED电压比半抛光的高40mV。(作者语:这意味着它的功率稍高,如果其他条件完全一样的话。)

每颗LED灯珠用同样的胶粘在铝柱上。

实验开始,打开开关,20分钟后,数据基本平稳,两个温度分别如下:

喷黑的:(右),半抛光的:(左)

喷黑的温度低17.4℃。

然后把铝柱放倒,温度会怎么样?

喷黑的:(右),半抛光的:(左)

相差20℃。作者在这里说,可供参考。

since the semi-polished aluminum has a very low thermal emissivity ~5%, as compared to the ~95% emissivity of black paint, and emissivity depends heavily on surface area.Regular anodized Aluminum has an emissivity of ~77.6%。

阳极氧化的热辐射率一般为77.6,而喷漆能达到0.95。而阳极氧化也有不同的类型,比如这种的辐射率能达到0.856:

Hard Anodize, Type III, has an emissivity of 83.5% to 85.6% depending on the color, for typical specimens, and this will vary a bit for the quality and thickness of the coating.

只要喷漆,黑色和白色的效果几乎是一样的,唯一的区别就是白色会反射红外线,而黑色不会。

现在来计算一下喷漆会比抛光效果好多少:

样品竖着放的时候:

抛光样品的温差 95.0C - 20.6C = 74.6 C rise喷黑样品的温差 77.6C - 20.6C = 57 C rise

喷黑比抛光好这么多:1-(57/77.4)*100= 23.4%

样品平着放的时候:抛光样品的温差 101.6C - 20.6C = 81.0 C rise喷黑样品的温差 81.6C - 20.6C = 61 C rise喷黑比抛光好这么多1-(61/81)*100= 24.7%

我们可以这么说,喷黑的温升会比抛光低24%,这作为一个经验参数是不太离谱的。

【如果这是一个手电筒,那么这个手电筒的表面温度在晴朗的夜里比在有乌云的夜里更凉快】,因为在晴朗的夜里,辐射源更容易【看见】低温的天空,而又乌云的话,相当于加了一层屏蔽层。

常见材料的辐射率

Emissivities of various materials and finishes:Aluminum, highly polished and degreased 0.027Aluminum, (6061-T6) highly polished 0.031Aluminum, highly polished 0.039Aluminum, semi-polished 0.05Aluminum, rough surface 0.07Aluminum, sand blasted, 0.21Aluminum, anodized 0.776**Aluminum, Hard Anodize, Type III 0.835 to 0.856 <---*****Brass, highly polished 0.03Brass, polished 0.10Brass, rubbed with 80-grit emery 0.20Brass, dull and tarnished 0.22Brass, oxidized 0.61Bronze, polished 0.10Bronze, porous + rough 0.55Cadmium, polished .02Chrome, polished 0.09 to 0.10Black Chrome 0.62Copper, highly mirror polished, 0.008Copper, polished 0.05Copper, burnished 0.07Copper, oxidized 0.65Copper, heavily oxidized 0.78Copper, oxidized to black 0.88

Gold, highly polished 0.02Iron, shiny, etched 0.16Iron, cast, polished 0.21Iron, cast, oxidized 0.64Lead, shiny 0.08Lead, gray 0.28Lead, oxidized 0.63Lead, red oxide powder 0.93

Nichrome, Clean 0.65Nichrome, Oxidized 0.60 – 0.85Nickel, polished 0.05Nickel, no polish 0.11Nickel, oxidized 0.37Black Nickel 0.66Platinum, shinny 0.05Platinum, Black 0.93

Rhodium, polished 0.03Rhodium Flash (0.0002" over 0.0005" Ni) 0.10 to 0.18Silver, high end observatory telescope mirror type finish, fresh, 0.01Silver, highly polished 0.02 to 0.03Silver, polished 0.08Stainless Steel, buffed 0.16Stainless Steel, sandblasted 0.440Stainless Steel, oxidized at 800℃ 0.85Steel, polished 0.07Steel, fresh rolled 0.24Steel, red rust 0.69Steel, oxidized 0.79Steel, rough surface 0.96

Silicon Carbide 0.80 to 0.95

Titanium, high polish, 0.04Titanium Alloy C110M, Polished 0.08 to 0.19Titanium Alloy C110M, Oxidized at 1000F 0.51 to 0.61Titanium(6AL-4V) bar, as received (oxidized) 0.472Titanium(6AL-4V) bar, polished, not brilliant 0.10Zinc, highly Polished 0.02Zinc, Lightly Oxidized 0.11

Lampblack, 0.95Candle soot, 0.95Graphite, rough cut across grain, 0.98Charcoal powder 0.963M Black Velvet #9560 1.0Martin Black Velvet Paint 0.94Krylon regular Flat Black 0.95Krylon regular Gloss black 0.91Sherwin Williams White Paint (A8W11) 0.87Sherwin Williams White Paint (F8WJ2O3O) 0.82Krylon regular Flat White 0.95

Paints with specific pigments:Blue, Cu2O3 0.94Black, CuO 0.96Green, Cu2O3 0.92Red, Fe2O3 0.91White, Al2O3 0.94White, Y2O3 0.90White, ZnO 0.95White, MgCO3 0.91White, ZrO2 0.95White, ThO2 0.90White, MgO 0.91White, PbCO3 0.93Yellow, PbO 0.90Yellow, PbCrO4 0.93

Paints, Aluminum 0.27 to 0.6710% Al 0.5226% Al 0.30Dow XP-310 0.22Gum Varnish (2 coats) 0.53Gum Varnish (3 coats) 0.50Cellulose Binder (2 coats) 0.34Ice, smooth 0.97Ice, rough 0.98

以上是无风,自然对流情况下。

那么有强制对流的时候,喷漆的效果怎么样呢?下面就来看看:

用一个90CFM 的风扇对着样品吹(方向是怎样的不知道)。

左边是喷漆的温度,右边是抛光的温度,几乎一样。

是不是因为离的太远了呢?把它们放近一点:

左边是喷漆的温度,右边是抛光的温度。

当靠得很近的时候黑色的会好一点,我觉得这是因为风吹不到的部位热量通过辐射散走了。而上边离得比较远的时候,辐射对温度的贡献很小,因为对流散热占据了绝大部分。

当然文章还有一些有趣的讨论比如人体对手电筒的影响的情况等等,有兴趣的同学可以自己看看。我就不转了。