STM32读取MPU6050陀螺仪

目录

一、硬件设计

1、模块说明

2、电气原理图

二、程序设计

1、工程创建

2、程序设计

(1)main程序

(2)IIC初始化

(3)串口1配置

(4)MPU6050初始化

(5)MPU6050角度状态获取

三、测试

四、工程下载连接

一、硬件设计

1、模块说明

STM32芯片型号:STM32C8T6

陀螺仪:MPU6050,使用I²C和CPU通讯,通讯引脚PB8、PB9

串口1对外通讯:引脚PA9、PA10

串口3接蓝牙通讯:引脚PB10、PB11

2、电气原理图

硬件设备

二、程序设计

1、工程创建

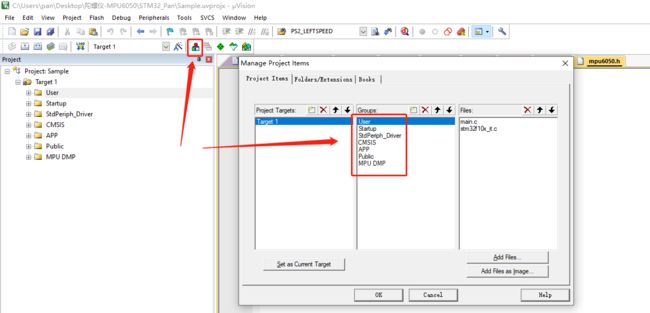

创建程序工程对应型号的单片机,在工程中添加下列文件夹

在工程根目录下添加下来文件夹,文件夹中添加相应的配置文件。

模板工程创建可以参加教程:STM32笔记1-库函数模板工程创建_Big_潘大师的博客-CSDN博客_site:csdn.net

这里提供一个创建好的模板STM32F103C8(LED灯闪烁运行指示)

https://download.csdn.net/download/panjinliang066333/86753318

User:用户程序,运行Main程序

App:各个功能块程序

Public:公用的程序

Startup:放置启动文件

StdPeriph_Driver:存储系统库文件

MPU DMP:陀螺仪库文件

2、程序设计

(1)main程序

#include "system.h"

#include "SysTick.h"

#include "SysDelay.h"

#include "led.h"

#include "i2c.h"

#include "mpu6050.h"

#include "usart.h"

int main()

{

u8 count=0;

u16 i=0;

SystemInit(); //系统初始化

SysDelay_Init(72); //自定义延时函数初始化

LED_Init();

USART1_Config(); //串口1初始化

USART3_Config(); //串口3初始化-接蓝牙

i2cInit(); //IIC初始化

SysDelay_ms(10); //10毫秒延时

MPU6050_Init(); //MPU6050 DMP陀螺仪初始化

while(1)

{

//LED闪烁

if(i%500==0)

{

led1=!led1;

}

//2秒执行一次

if(i%2000==0)

{

count++;

printf("count:%d \r\n",count);

printf("Pitch: %.2f ,Roll: %.2f,Yaw: %.2f \r\n",Pitch,Roll,Yaw); //Pitch,Roll,Yaw数据串口传递

}

/*获取MPU6050角度状态*/

//在串口数据发送之后执行

MPU6050_Pose(); //Pitch翻滚,Roll俯仰,Yaw偏航

SysDelay_ms(1); //1毫秒延时

i++;

}

}(2)IIC初始化

void i2cInit(void)

{

GPIO_InitTypeDef gpio;

//ÒѸü¸Ä

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOB , ENABLE);

gpio.GPIO_Pin = GPIO_Pin_8 | GPIO_Pin_9;

gpio.GPIO_Speed = GPIO_Speed_2MHz;

gpio.GPIO_Mode = GPIO_Mode_Out_OD;

GPIO_Init(GPIOB, &gpio);

}(3)串口1配置

void USART1_Config(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

USART_InitTypeDef USART_InitStructure;

// NVIC_InitTypeDef NVIC_InitStructure;

/* config USART1 clock */

RCC_APB2PeriphClockCmd(RCC_APB2Periph_USART1 | RCC_APB2Periph_GPIOA, ENABLE);

/* USART1 GPIO config */

/* Configure USART1 Tx (PA.09) as alternate function push-pull */

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_9;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

/* Configure USART1 Rx (PA.10) as input floating */

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_10;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_IN_FLOATING;

GPIO_Init(GPIOA, &GPIO_InitStructure);

/* USART1 mode config */

USART_InitStructure.USART_BaudRate = 115200;

//USART_InitStructure.USART_BaudRate = 9600;

USART_InitStructure.USART_WordLength = USART_WordLength_8b;

USART_InitStructure.USART_StopBits = USART_StopBits_1;

USART_InitStructure.USART_Parity = USART_Parity_No ;

USART_InitStructure.USART_HardwareFlowControl = USART_HardwareFlowControl_None;

USART_InitStructure.USART_Mode = USART_Mode_Rx | USART_Mode_Tx;

USART_Init(USART1, &USART_InitStructure);

USART_Cmd(USART1, ENABLE);

}(4)MPU6050初始化

void MPU6050_Init(void)

{

int result=0;

//IIC_Init();

result=mpu_init();

if(!result)

{

PrintChar("mpu initialization complete......\n "); //mpu initialization complete

if(!mpu_set_sensors(INV_XYZ_GYRO | INV_XYZ_ACCEL)) //mpu_set_sensor

PrintChar("mpu_set_sensor complete ......\n");

else

PrintChar("mpu_set_sensor come across error ......\n");

if(!mpu_configure_fifo(INV_XYZ_GYRO | INV_XYZ_ACCEL)) //mpu_configure_fifo

PrintChar("mpu_configure_fifo complete ......\n");

else

PrintChar("mpu_configure_fifo come across error ......\n");

if(!mpu_set_sample_rate(DEFAULT_MPU_HZ)) //mpu_set_sample_rate

PrintChar("mpu_set_sample_rate complete ......\n");

else

PrintChar("mpu_set_sample_rate error ......\n");

if(!dmp_load_motion_driver_firmware()) //dmp_load_motion_driver_firmvare

PrintChar("dmp_load_motion_driver_firmware complete ......\n");

else

PrintChar("dmp_load_motion_driver_firmware come across error ......\n");

if(!dmp_set_orientation(inv_orientation_matrix_to_scalar(gyro_orientation))) //dmp_set_orientation

PrintChar("dmp_set_orientation complete ......\n");

else

PrintChar("dmp_set_orientation come across error ......\n");

if(!dmp_enable_feature(DMP_FEATURE_6X_LP_QUAT | DMP_FEATURE_TAP |

DMP_FEATURE_ANDROID_ORIENT | DMP_FEATURE_SEND_RAW_ACCEL | DMP_FEATURE_SEND_CAL_GYRO |

DMP_FEATURE_GYRO_CAL)) //dmp_enable_feature

PrintChar("dmp_enable_feature complete ......\n");

else

PrintChar("dmp_enable_feature come across error ......\n");

if(!dmp_set_fifo_rate(DEFAULT_MPU_HZ)) //dmp_set_fifo_rate

PrintChar("dmp_set_fifo_rate complete ......\n");

else

PrintChar("dmp_set_fifo_rate come across error ......\n");

run_self_test(); //自检

if(!mpu_set_dmp_state(1))

PrintChar("mpu_set_dmp_state complete ......\n");

else

PrintChar("mpu_set_dmp_state come across error ......\n");

}

}(5)MPU6050角度状态获取

void MPU6050_Pose(void)

{

dmp_read_fifo(gyro, accel, quat, &sensor_timestamp, &sensors,&more);

/* Gyro and accel data are written to the FIFO by the DMP in chip frame and hardware units.

* This behavior is convenient because it keeps the gyro and accel outputs of dmp_read_fifo and mpu_read_fifo consistent.

**/

/*if (sensors & INV_XYZ_GYRO )

send_packet(PACKET_TYPE_GYRO, gyro);

if (sensors & INV_XYZ_ACCEL)

send_packet(PACKET_TYPE_ACCEL, accel); */

/* Unlike gyro and accel, quaternions are written to the FIFO in the body frame, q30.

* The orientation is set by the scalar passed to dmp_set_orientation during initialization.

**/

if(sensors & INV_WXYZ_QUAT )

{

q0 = quat[0] / q30;

q1 = quat[1] / q30;

q2 = quat[2] / q30;

q3 = quat[3] / q30;

//Pitch翻滚,Roll俯仰,Yaw偏航

Pitch = asin(-2 * q1 * q3 + 2 * q0* q2)* 57.3; // pitch

Roll = atan2(2 * q2 * q3 + 2 * q0 * q1, -2 * q1 * q1 - 2 * q2* q2 + 1)*57.3; // roll

Yaw = atan2(2*(q1*q2 + q0*q3),q0*q0+q1*q1-q2*q2-q3*q3) * 57.3; //yaw

}

}三、测试

打开串口调试助手,可以接收到单片机发送过来的数据,转动单片机板子可以发现YAW(偏航)数据发生变化。

四、工程下载连接

https://download.csdn.net/download/panjinliang066333/86753201