NK-980IOT测评之使用EBI驱动LCD

特征

- 三个独立芯片选择引脚,可设置极性,支持三个设备,时序独立设置

- 数据总线和地址总线分开。

- 每个设备支持1MB空间

- 8/16位数据宽度

- 支持8080模式LCD接口

- 支持PDMA

- 支持设置读写空闲时间

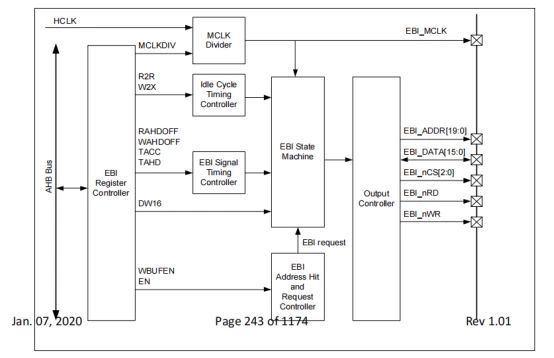

- 可选内部HCLK分频得到MCLK或者外部EBI_MCLK

- 支持地址总线和数据总线分开

配置

- 时钟使能

EBI (CLK_HCLKEN[9])

- 复位模块

EBIRST (SYS_AHBIPRST[3])

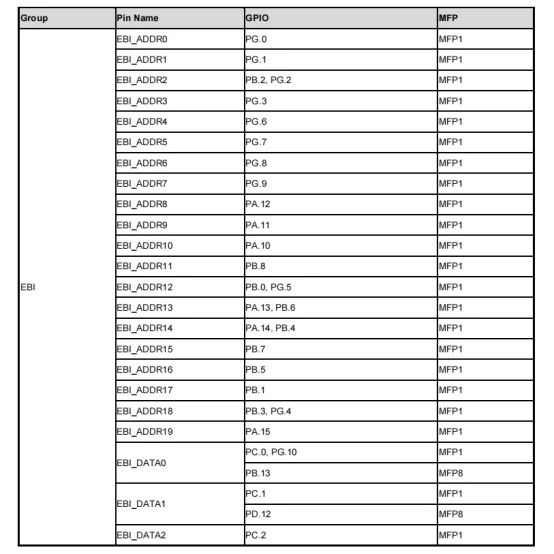

- 引脚

功能

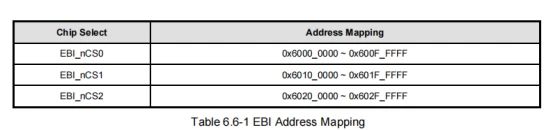

地址映射

三个片选分别对应地址如下:

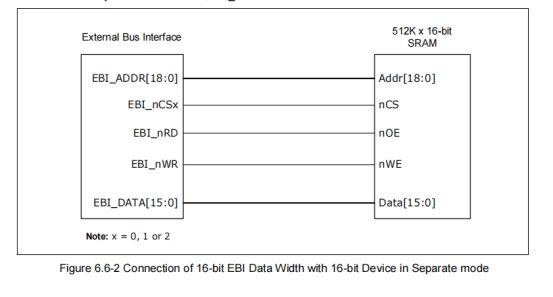

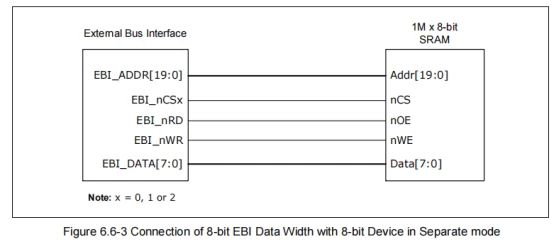

连接

地址总线和数据总线分开模式

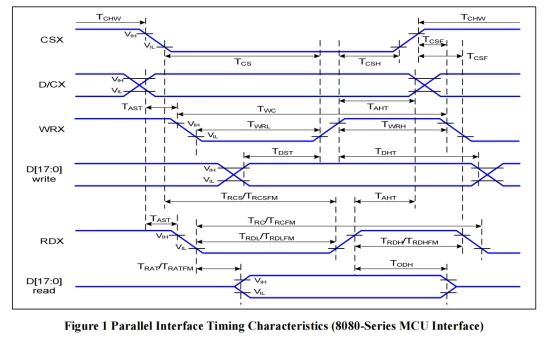

读写时序

tASU:地址建立时间,CS拉低到RD或WR拉低的时间,连续读模式CACCESS=1,tASU不需要.

tACC:RD,WD拉低的时间,数据访问时间,即给对方去读数据的时间。

tAHD:数据保持时间,即RD,WR拉高后到CS拉高的时间。

寄存器

EBI_CTLx

设置时钟分频,使能EBI功能,总线宽度设置,CS极性等

EBI_TCTLx

设置时序参数

使用EBI驱动LCD设计

硬件设计

LCD选型

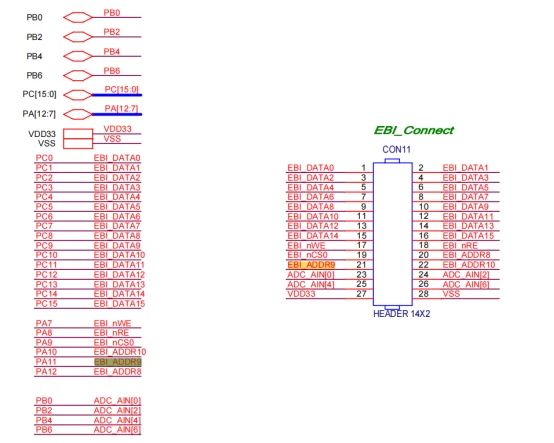

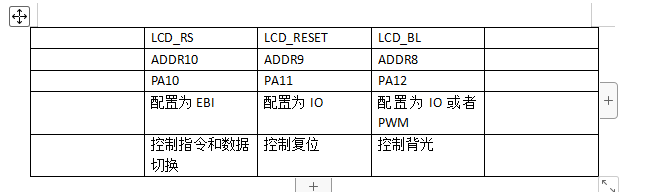

从原理图可以看出CON11为EBI接口,设计时实际就是预留给LCD使用的,可以使用EBI接口,接8080模式16bit的LCD屏。

对应如下:

从淘宝上挑选了一个便宜的2.4寸支持8080模式的触摸屏。使用的驱动芯片是ST7789V。

(链接就不上了,可以以图搜图搜索购买同款)

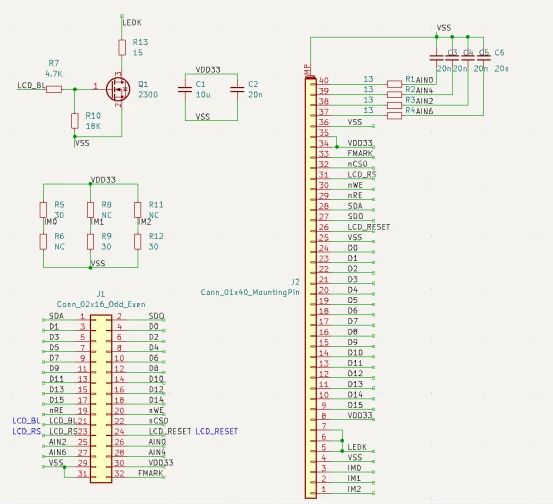

原理图和PCB设计

使用KiCAD设计了原理图和PCB

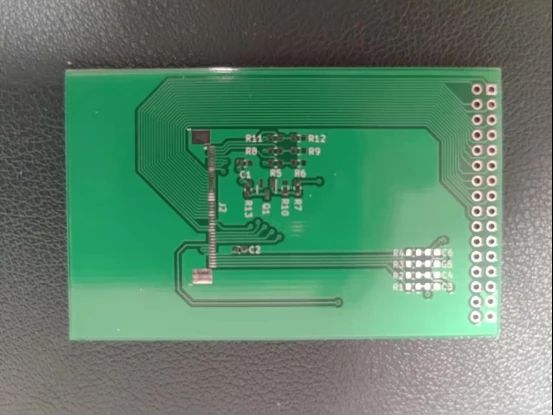

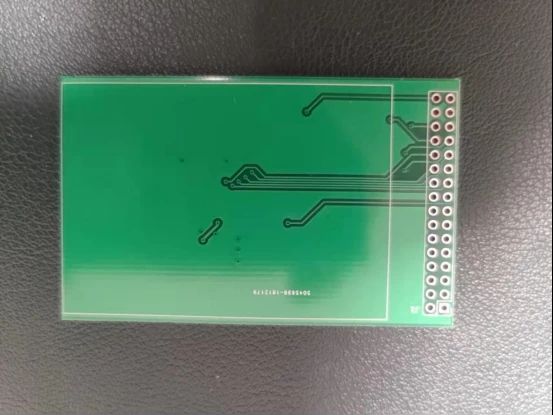

生产焊接

华秋DFM正好在搞活动,可以减免30打样双面板,所以实际只花了8块钱的运费打样。

三四天就生产完到货了,非常快。

在生产时刚好淘宝下单将BOM表的物料采购下,我手里大部分都有就买了个FFC的座子,和2.54的排母。

打样加上物料30块多点就搞定了。

焊接手工,十来分钟就搞定了。

回来的PCB

焊接之后,由于手头没有洗板水所以焊接后残留很多松香渣滓,可以买点高浓度酒精97%以上清洗下。

插入到开发板

原理分析

用的CS0片选,所以地址空间为0x6000_0000 ~ 0x600F_FFFF

由于RS引脚接到了ADDR10,而且使用的是16bit模式,所以地址中的1<<11位对应ADDR10即RS。

如果是8位模式则一一对应,地址中的1<<10位对应ADDR10即RS

写地址0x60000000 | 1<<11则ADDR10为1,RS=1表示数据

写地址0x60000000 | 0<< 11则ADDR10为0,RS=0表示命令

所以读写命令或者数据只需要读写地址0x60000000 | 1<<11和0x60000000 | 0<< 11即可。

液晶屏的参数如下

根据以上

先确认HCLK时钟分频2^x次得到MCLK,x=0~7最大分频128。

sysGetClock(SYS_HCLK))可以获取HCLK单位为M

分频x则MCLK为x/HCLK uS = 1000*x/HCLK nS

nu_clocks可以打印当前时钟配置

代码编写

见lcd.c

#include

#include

#include "nuc980.h"

#include "nu_ebi.h"

#include "nu_sys.h"

#include

#include

#define LCD_XSIZE 320

#define LCD_YSIZE 240

#define CMD_ADDR (0x60000000 | 0u<<11)

#define DAT_ADDR (0x60000000 | 1u<<11)

#define LLCD_WRITE_CMD(cmd) *((volatile uint16_t*)CMD_ADDR)=cmd

#define LLCD_WRITE_DATA(dat) *((volatile uint16_t*)DAT_ADDR)=dat

#define LLCD_READ_DATA() *((volatile uint16_t*)DAT_ADDR)

#define MCLK_DIVSET 5 /* 0~7 75m 26ns */

#define MCLK_DIVVAL 32 /* 1~128分频 */

#define R2R 100 /* >10nS */

#define W2X 100 /* >10nS */

#define TAHD 100 /* >10nS */

#define TACC 3000 /* >355nS */

void lcd_init(void)

{

uint32_t hclk = sysGetClock(SYS_HCLK);

uint32_t r2r;

uint32_t w2x;

uint32_t tahd;

uint32_t tacc;

/* 1. 引脚配置 */

/* PA12背光 EBI_ADDR8 */

rt_pin_mode(NU_GET_PININDEX(NU_PA, 12), PIN_MODE_OUTPUT);

/* PA11复位 EBI_ADDR9 */

rt_pin_mode(NU_GET_PININDEX(NU_PA, 11), PIN_MODE_OUTPUT);

/* PA10 EBI_ADDR10 (LCD_RS) MFP1

PA9 EBI_nCS0 MFP1

PA8 EBI_nRE MFP1

PA7 EBI_nWE MFP1

PC0~PC15 EBI_DATA0~EBI_DATA15 MFP1

*/

M32(REG_SYS_GPC_MFPL) = 0x11111111; /*PC0~PC15 MFP1 */

M32(REG_SYS_GPC_MFPH) = 0x11111111;

M32(REG_SYS_GPA_MFPL) = (M32(REG_SYS_GPA_MFPL) & 0x0FFFFFFF) | 0x10000000; /* PA7 MFP1 */

M32(REG_SYS_GPA_MFPH) = (M32(REG_SYS_GPA_MFPH) & 0xFFFFF000) | 0x00000111; /* PA8 PA9 PA10 MFP1 */

/* 2. 时钟配置 */

M32(REG_CLK_HCLKEN) |= (1u<<9); /* 使能时钟 */

/* 3. 复位 */

M32(REG_SYS_AHBIPRST) |= (1u<<3); /* 复位EBI */

M32(REG_SYS_AHBIPRST) &= ~(1u<<3); /* 结束复位 */

/* 4. 时序 */

EBI->CTL0 |= 1u<<24; /* EBI write buffer Enabled */

EBI->CTL0 = (EBI->CTL0 & (~(0x07<<8))) | (MCLK_DIVVAL<<8);

EBI->CTL0 |= 0u<<4; /* Continuous data access mode tASU cycle is bypass. */

EBI->CTL0 |= 1u<<1; /* 16bit. */

r2r = R2R/(1000*MCLK_DIVVAL/hclk) & 0x0F;

if(r2r==0)

{

r2r=1;

}

w2x = W2X/(1000*MCLK_DIVVAL/hclk) & 0x0F;

if(w2x==0)

{

w2x=1;

}

tahd = TAHD/(1000*MCLK_DIVVAL/hclk) & 0x07;

if(tahd==0)

{

tahd=1;

}

tacc = TACC/(1000*MCLK_DIVVAL/hclk) & 0x1F;

if(tacc==0)

{

tacc=1;

}

EBI->TCTL0 = (r2r<<24) | (0 <<23) | (0<<22) | (w2x<<12) | ((tahd-1)<<8) | ((tacc-1)<<3);

EBI->CTL0 |= 1u<<0; /* EBI function Enabled. */

/* 5. LCD复位 */

rt_pin_write(NU_GET_PININDEX(NU_PA, 11), PIN_LOW);

/* 手册P48 延时大于10uS */

rt_thread_mdelay(1);

rt_pin_write(NU_GET_PININDEX(NU_PA, 11), PIN_HIGH);

/* LCD寄存器初始化 */

rt_thread_mdelay(120);

//---------------------------------------------------------------------------------------------------//

LLCD_WRITE_CMD (0x11);

rt_thread_mdelay(120); //Delay 120ms

//------------------------------display and color format setting--------------------------------//

LLCD_WRITE_CMD (0x36);

LLCD_WRITE_DATA (0x00);

LLCD_WRITE_CMD (0x3a);

LLCD_WRITE_DATA (0x05);

//--------------------------------ST7789V Frame rate setting----------------------------------//

LLCD_WRITE_CMD (0xb2);

LLCD_WRITE_DATA (0x0c);

LLCD_WRITE_DATA (0x0c);

LLCD_WRITE_DATA (0x00);

LLCD_WRITE_DATA (0x33);

LLCD_WRITE_DATA (0x33);

LLCD_WRITE_CMD (0xb7);

LLCD_WRITE_DATA (0x35);

//---------------------------------ST7789V Power setting--------------------------------------//

LLCD_WRITE_CMD (0xbb);

LLCD_WRITE_DATA (0x28);

LLCD_WRITE_CMD (0xc0);

LLCD_WRITE_DATA (0x2c);

LLCD_WRITE_CMD (0xc2);

LLCD_WRITE_DATA (0x01);

LLCD_WRITE_CMD (0xc3);

LLCD_WRITE_DATA (0x0b);

LLCD_WRITE_CMD (0xc4);

LLCD_WRITE_DATA (0x20);

LLCD_WRITE_CMD (0xc6);

LLCD_WRITE_DATA (0x0f);

LLCD_WRITE_CMD (0xd0);

LLCD_WRITE_DATA (0xa4);

LLCD_WRITE_DATA (0xa1);

//--------------------------------ST7789V gamma setting---------------------------------------//

LLCD_WRITE_CMD (0xe0);

LLCD_WRITE_DATA (0xd0);

LLCD_WRITE_DATA (0x01);

LLCD_WRITE_DATA (0x08);

LLCD_WRITE_DATA (0x0f);

LLCD_WRITE_DATA (0x11);

LLCD_WRITE_DATA (0x2a);

LLCD_WRITE_DATA (0x36);

LLCD_WRITE_DATA (0x55);

LLCD_WRITE_DATA (0x44);

LLCD_WRITE_DATA (0x3a);

LLCD_WRITE_DATA (0x0b);

LLCD_WRITE_DATA (0x06);

LLCD_WRITE_DATA (0x11);

LLCD_WRITE_DATA (0x20);

LLCD_WRITE_CMD (0xe1);

LLCD_WRITE_DATA (0xd0);

LLCD_WRITE_DATA (0x02);

LLCD_WRITE_DATA (0x07);

LLCD_WRITE_DATA (0x0a);

LLCD_WRITE_DATA (0x0b);

LLCD_WRITE_DATA (0x18);

LLCD_WRITE_DATA (0x34);

LLCD_WRITE_DATA (0x43);

LLCD_WRITE_DATA (0x4a);

LLCD_WRITE_DATA (0x2b);

LLCD_WRITE_DATA (0x1b);

LLCD_WRITE_DATA (0x1c);

LLCD_WRITE_DATA (0x22);

LLCD_WRITE_DATA (0x1f);

LLCD_WRITE_CMD (0x29);

/* 开背光 */

rt_pin_write(NU_GET_PININDEX(NU_PA, 12), PIN_HIGH);

#if 0 /* 逻辑分析仪测试波形使用 */

while(1)

{

LLCD_WRITE_CMD(0x00);

LLCD_WRITE_CMD(0x01);

LLCD_WRITE_CMD(0x02);

LLCD_WRITE_CMD(0x03);

LLCD_WRITE_DATA(0x00);

LLCD_WRITE_DATA(0x01);

LLCD_WRITE_DATA(0x02);

LLCD_WRITE_DATA(0x03);

LLCD_READ_DATA();

rt_thread_mdelay(1);

}

#endif

}

void lcd_setpoint(uint16_t x ,uint16_t y, uint16_t color)

{

LLCD_WRITE_CMD(0x2A);

LLCD_WRITE_DATA(x>>8);

LLCD_WRITE_DATA(x&0XFF);

LLCD_WRITE_CMD(0x2B);

LLCD_WRITE_DATA(y>>8);

LLCD_WRITE_DATA(y&0XFF);

LLCD_WRITE_CMD(0x2C);

LLCD_WRITE_DATA(color);

}

void lcd_clear(uint16_t color)

{

LLCD_WRITE_CMD(0x2A);

LLCD_WRITE_DATA(0);

LLCD_WRITE_DATA(0);

LLCD_WRITE_CMD(0x2B);

LLCD_WRITE_DATA(0);

LLCD_WRITE_DATA(0);

LLCD_WRITE_CMD(0x2C);

for(uint32_t i=0;i 硬件/时序调试

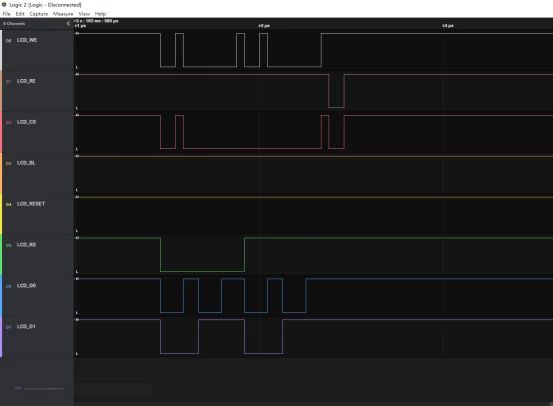

焊接完后要先确认是否有短路,再上电。

首先先确认各引脚是不是对,对于RESET和BL引脚是作为IO的直接翻转用示波器或者逻辑分析仪看是否正确,

对于其他EBI引脚按照如下测试代码

#if 0 /* 逻辑分析仪测试波形使用 */

while(1)

{

LLCD_WRITE_CMD(0x00);

LLCD_WRITE_CMD(0x01);

LLCD_WRITE_CMD(0x02);

LLCD_WRITE_CMD(0x03);

LLCD_WRITE_DATA(0x00);

LLCD_WRITE_DATA(0x01);

LLCD_WRITE_DATA(0x02);

LLCD_WRITE_DATA(0x03);

LLCD_READ_DATA();

rt_thread_mdelay(1);

}

#endif用逻辑分析仪去看是否信号线是否都对,首先确认信号线是否一一对应,不对就检查原理图和PCB和焊接。

然后确认信号是否符合要求,不符合就确认寄存器的配置是否正确。

nk-980-iot-testlcd-pcb测试信号 使用Logic 2.3.47打开.sal 是我这里抓取到波形,可以打开回放,和上面的测试代码对应。

刷屏测试

确认时序都对后编写刷屏程序,按照RGB显示,

代码如下

#if LCD_TEST

lcd_clear(0xF800);

rt_thread_mdelay(1000);

lcd_clear(0x07E00);

rt_thread_mdelay(1000);

lcd_clear(0x0001F);

rt_thread_mdelay(1000);

#endif效果如下:

b7ccb72a8698f533e3306ed234cd55c9.mp4

源码

NK-980IOT-TEST: NK-980IOT-TEST

LCD相关资料在lcd-pcb目录下。

总结

EBI接口驱动8080接口的LCD非常方便,本次设计也比较顺利,一次就成功,其中逻辑分析仪非常重要,用来分析时序没有他不行,另外嘉立创的打样活动非常不错,可以去看看。

下次测试下性能,优化下时序,将时序尽可能提高到最快,尽可能提高刷屏速度。

后面再移植GUI,暂时选定lvgl或者emwin。

后面再添加ADC测评,添加驱动支持。