100BASE-T1 Ethernet: the evolution of automotive networking

From REF:

https://www.ti.com/lit/wp/szzy009/szzy009.pdf?ts=1643252174906&ref_url=https%253A%252F%252Fcn.bing.com%252F

Automotive electrical systems continue to increase in complexity, with a growing number of electronic control units (ECUs) implemented in vehicles. These ECUs are sharing real-time data on a much broader level, thus increasing the demand for network bandwidth.

To address the bandwidth issue, automotive companies partnered with leading integrated circuit (IC) manufacturers and system developers to establish an entirely new Ethernet standard tailored for automotive communication networks

The Institute of Electrical and Electronic Engineers (IEEE) 802.3bw standard (also known as 100BASE-T1, previously known as BroadR-Reach) is a 100 Mbps automotive Ethernet standard aimed at increasing data throughput, meeting strong automotive emissions standards, and reducing cabling weight and cost in automotive networking. By using the basic principles of superposition and specific encoding and scrambling schemes, 100BASE-T1 reduces electromagnetic interference (EMI), cabling weight, cost and footprint size compared to Ethernet standards 10BASE-T and 100BASE-TX.

Over the years, automotive electrical systems have become more complex, mainly driven by advancements in infotainment, advanced driverassistance systems (ADAS), power trains and body electronics. These systems require faster communication networks due to the large amount of real-time data and firmware/software shared between various electronic control units (ECUs) in vehicles today.

IEEE 802.3bw (100BASE-T1) is a new physical layer (PHY) communication protocol developed by automotive companies along with leading integrated circuit (IC) manufacturers and system developers.

100BASE-T1 is a viable solution for larger bandwidth demands at 100 Mbps communication speeds over an unshielded single twisted-pair cable. By using techniques such as superposition, encoding and scrambling schemes (along with a few passive components), 100BASE-T1 reduces electromagnetic interference (EMI), cabling weight, cost and footprint size compared to traditional Fast Ethernet (100BASETX) solutions. The goal of this paper is to investigate possible use cases of 100BASE-T1 in automotive systems based on the types of data in automotive networks, and introduce how the physical layer creates an automotive-qualified network compared to past Ethernet standards.

Ethernet in automotive

Although Ethernet is a popular long-standing communication protocol for commercial and industrial applications, it was not widely adopted in the automotive industry until the advent of 100BASE-T1. Some vehicles have used 100BASE-TX for onboard diagnostic (OBD) scan tools. However, 100BASE-TX was not able to grow within the automotive ecosystem because it requires two twisted-pair cables and does not meet strict Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 Class 5 radiated emissions limits [1].

100BASE-T1 was developed to meet the needs of an automotive system. It only requires an unshielded single twisted-pair(USTP) cable to transmit and receive data at 100 Mbps speeds over communication distances of at least 15 m. 100BASE-T1 emissions profile stays under CISPR 25 Class 5 Annex G stripline method and other automotive emission standards such as TC8 from Open Alliance [1], [2], [3]. 100BASE-T1 standardizes the in-vehicle ecosystem to a network architecture, simplifying the overall communication between ECUs and possibly even eliminating the need for older or less prevalent protocols such as Media Oriented Systems Transport (MOST) or FlexRay.

100BASE-T1 can enable the communication of audio, video, connected car, firmware/software and calibration data within vehicles using the audio video bridging (AVB) collection of Ethernet protocols over unshielded single twisted-pair cable. The AVB collection of standards, developed by the IEEE Time-Sensitive Networking Task Group, has low and deterministic latency, synchronized nodes and traffic shaping [1], [4]. These aspects are important for communicating the various types of information in automotive systems and enable 100BASE-T1 to carry different types of data with various priorities (low data rate and high priority vs. high data rate and low priority, as well as time synchronization).

Ethernet for audio and video data

100BASE-T1 paired with AVB can transfer both audio and video data. This creates an opportunity for Ethernet in the infotainment and ADAS domains. AVB designates a certain amount of bandwidth for audio and video data only. The amount of bandwidth partitioned is adjustable and chosen by the original equipment manufacturer (OEM). Typically, 75 Mbps of bandwidth is allocated for audio and video streams, with the remaining 25 Mbps for data streams [4].

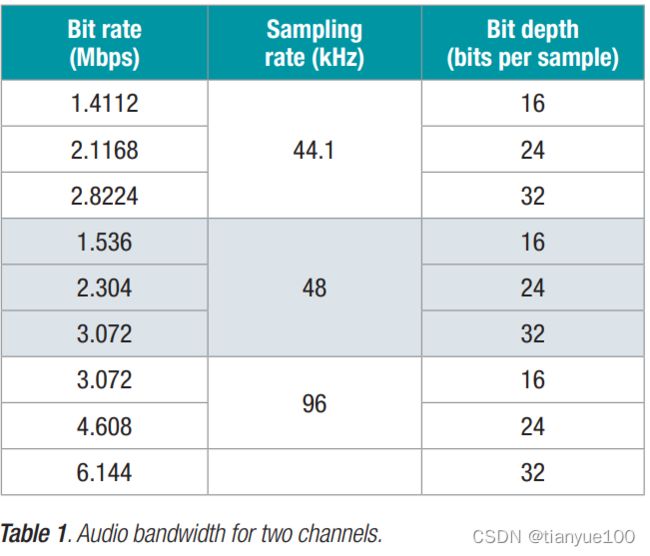

Table 1 shows the necessary bandwidth needed for audio based on the sampling rate and bit depth for two channels using Equation 1:

Bit rate = Sampling rate × Bit depth × Number of channels (1)

Based on Table 1, 100BASE-T1 easily supports bandwidth requirements of 44.1 kHz, 48 kHz and even 96 kHz sampled audio with bit depths of as much as 32 bits per sample. For example, a typical CD is sampled at 44.1 kHz and has a bit depth of 16 bits per sample. High-resolution audio is often sampled at 96 kHz with a bit depth of 24 bits per sample. 100BASE-T1 links fully support both.

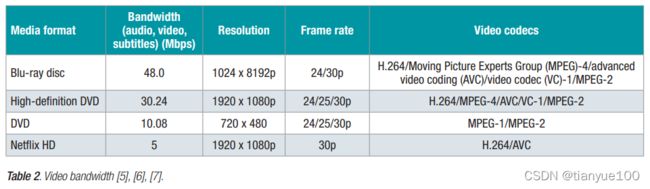

On the other hand, video transmission requires much more bandwidth. Table 2 shows several different video formats with their respective bandwidth requirements. Table 2 also estimates the amount of video bandwidth necessary for different media formats, resolutions and frame rates.

Based on the data in Table 2, the 75 Mbps bandwidth of AVB paired with 100BASE-T1 should be able to handle a couple of video channels in the infotainment domain. Still, in ADAS applications, uncompressed video data from cameras can easily have bandwidth requirements over 1 Gbps [8]. Unless the video is compressed prior to transmission, 100BASE-T1 may not be suitable. Furthermore, video transmitted via Ethernet requires a microcontroller (MCU) to both perform video compression and to provide a Media Access Control (MAC) layer for Ethernet communications. Since cameras provide up to several gigabits of uncompressed data at the main computing device, 100BASE-T1 is not the right solution. However, 100BASE-T1 is a viable option for video communications when integrating an MCU within a camera (such as a smart backup camera).

Connected car applications

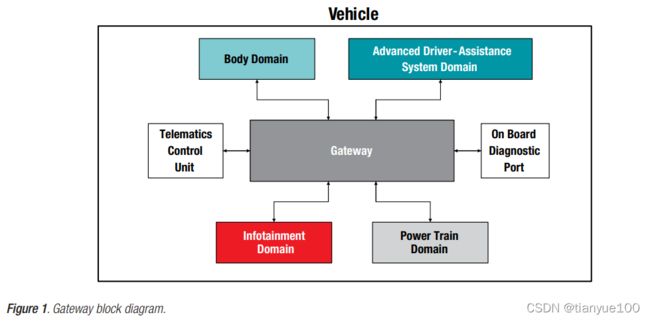

100BASE-T1 is not limited to AVB applications. A key connection within the vehicle is the telematics control unit (TCU), which controls the wireless tracking of and communication to and from the vehicle. Communication from the TCU to the automotive gateway (which bridges various communication domains in a vehicle to each another – see Figure 1) enables access to the cloud, facilitating software/ firmware updates over the air for various ECUs.

An important factor to consider for 100BASE-T1 is that some automotive 4G Long-Term Evolution (LTE) modems implemented in the TCU can operate at 300-400 Mbps, which is why 1000BASE-T1 as well as multigigabit solutions is inevitable.

Firmware/software and calibration data

Firmware/software updates and calibration are faster when using 100BASE-T1 Ethernet, reducing downtime for vehicle updates. Most vehicles have a 100BASE-TX OBD port for reading diagnostics data and updating or flashing software/firmware. By connecting various ECUs in a vehicle via 100BASE-T1 to a central gateway with an OBD port, updates can occur more quickly than existing solutions with various communication buses; Controller Area Network (CAN) operates at 1 Mbps, CAN Flexible Data-Rate (CAN-FD) operates at greater than 2 Mbps and FlexRay operates at 10 Mbps [1], [4].

100BASE-T1 can also facilitate an ECU’s calibration when nearing manufacturing completion. Using 100BASE-T1 Ethernet to transfer data helps reduce calibration time, which decreases overall manufacturing time.

100BASE-T1 PHY basics

The “Ethernet in Automotive” section discussed the benefits of 100BASE-T1 and the types of data that are typically transferred in an automotive network. This next section discusses 100BASE-T1 in-depth from a PHY perspective, clarifying how 100BASE-T1 meets automotive system requirements of low EMI, low cost, reduced cabling weight and higher bandwidth.

100BASE-T1 encoding method for reduced EMI at 100Mbps speeds

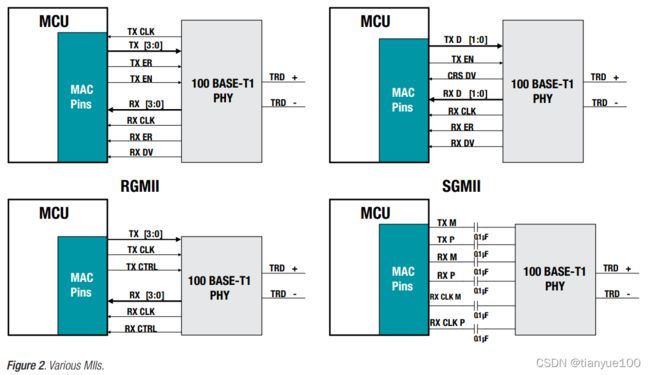

100BASE-T1 operates with a unique 4-bit to 3-bit (4B3B), 3-bit to 2-ternary pair (3B2T) and threelevel pulse amplitude modulation (PAM3) encoding scheme to achieve reduced emissions compared to Fast Ethernet. A 100BASE-T1 PHY performs all necessary scrambling and encoding before transmission over the unshielded single twisted-pair cable. 100BASE-T1 is transparent from a MAC in that the existing Media Independent Interface (MII) has not changed. There are four main xMIIs currently in use today for 100BASE-T1:

• MII:

- 4-bit-wide data interface

- Receive and transmit controls

- Receive and transmit clocks

• Reduced Media Independent Interface (RMII):

- 2-bit-wide data interface

- Receive and transmit controls

- Single clock reference

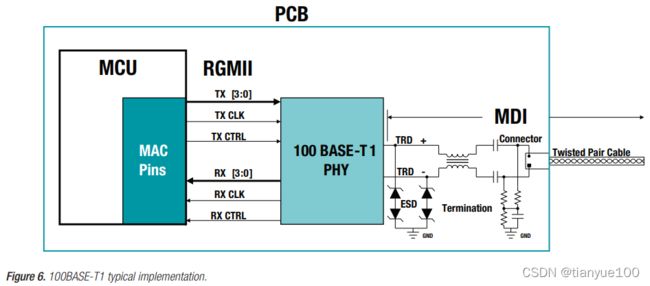

• Reduced Gigabit Media Independent Interface (RGMII):

- 4-bit-wide data interface

- Receive and transmit controls

- Receive and transmit clocks

• Serial Gigabit Media Independent Interface (SGMII):

- 2-pin low-voltage differential signaling (LVDS) receive path

- 2-pin LVDS transmit path

Figure 2 shows the signaling of a MAC and PHY depending on the interface. After receiving data from the MAC, the Ethernet PHY encodes, scrambles and serializes the data [5]. These processes prepare the data for the analog front end of the PHY, which then transmits the data out onto the unshielded single twisted-pair cable to a link partner.

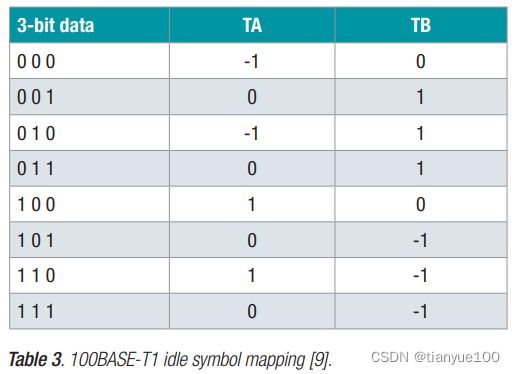

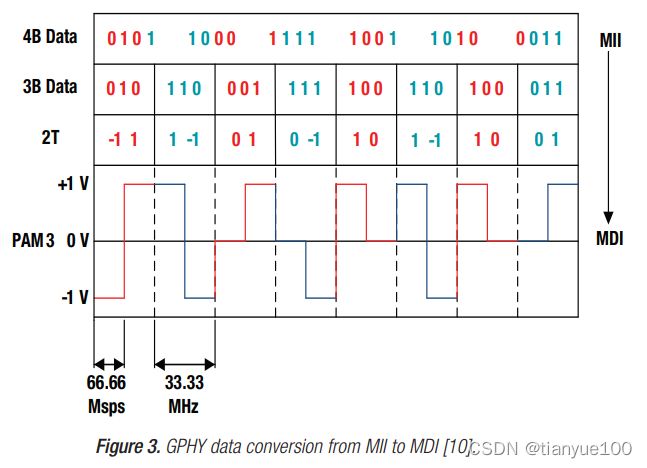

For example, a 100BASE-T1 PHY communicating with a MAC via RGMII will receive four parallel bits clocked at 25 MHz (100 Mbps total). The PHY converts these four bits to three bits and increases the clock frequency to 33 1/3 MHz to maintain the 100 Mbps bit rate. (If a frame is not divisible by three, the PHY adds stuffing bits to enable proper conversion. The link partner removes these stuffing bits before transfer to the MAC.) Using each group of three bits, a ternary pair (2T) is generated by the PHY based off of the symbol map shown in Table 3.

Finally, the ternary pair vector (TA, TB) is transmitted using three-level pulse amplitude modulation (PAM3) at a 66 2/3 MHz fundamental frequency. Figure 3 shows the data converted from MII to the Medium Dependent Interface (MDI) through the PHY. Looking at the PAM3 signal, it is easy to see that every 33 1/3 MHz period will represent three bits of data and thus transfer data at 100 Mbps. This signal is sent using three voltage levels (+1 V, 0 V and -1 V) with less than 2.2 V peak-to-peak (when measured with 100 Ω differential termination) [9].

PAM3 is transmitted on the MDI, which includes the connector for the cable and the single twistedpair cable itself, as well as any passive external components used for additional low-pass filtering and common-mode (CM) rejection. The MDI connector and unshielded single twisted-pair cable combination must meet electrical specifications such as return loss, conversion loss and fault tolerance, as specified in Section 96.8 of the 100BASE-T1 standard MDI specification.

Ethernet protocols have different specifications for scrambling, serializing and encoding data based on their target application. For comparison, 100BASE-TX transfers data at 125 MHz using Multi-Level Transmit (MLT-3). The fundamental frequency is higher than 100BASE-T1 (66 2/3 MHz) and requires a dedicated twisted pair for transmit and receive. 100BASE-T1 only requires approximately 33.3MHz of bandwidth, close to half that of 100BASE-TX. This means that you can use a lower-quality cable (reducing cost) while offering improved filtering for better emissions and immunity, which are both critical in automotive applications. Also, spectral efficiency increases when using 100BASE-T1’s method of 3B2T signal mapping and PAM3 modulation over 100BASE-TX’s 4B5B encoding to MLT-3, thus reducing emissions by reducing the bandwidth needed to send the same amount of data.

Transmit/receive data over an unshielded single twisted pair

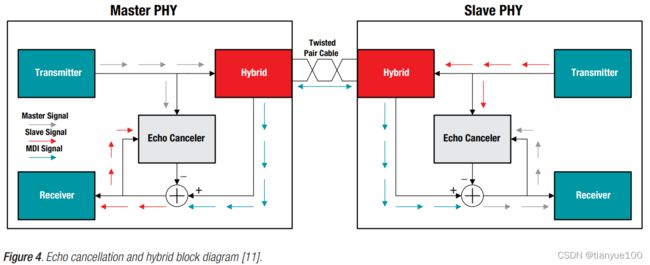

100BASE-T1 is a physical full-duplex interface enabling transmission and reception on the same pair, unlike 10BASE-T and 100BASE-TX, where transmission and reception are on dedicated pairs. Shared media reduces overall cable weight in the vehicle, not only reducing material cost but also improving fuel efficiency. Physical full duplex is accomplished through the principles of superposition. 100BASE-T1 PHYs have integrated hybrids and use echo cancellation to remove their own transmitted signal and extract the received information from a link partner. In order to do this, one PHY is dedicated as a master and the other as a slave. When two 100BASE-T1 PHYs connect, they undergo a training process that leads to both the device under test (DUT) and the link partner transmitting information at the same frequency with the same phase. Figure 4 shows a simplified block diagram of hybrid and echo cancellation within each PHY.

Additional components

Before the PAM3 signaling leaves or enters the board, several components condition the signal for transmission and reception. The goals of these external components are to isolate the MDI to prevent ground loops and driver DC offset, to improve CM noise filtering, and to reduce radiated emissions while maintaining high immunity [9], [12].

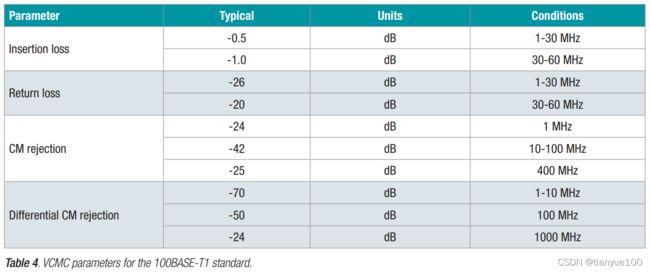

Filtering CM noise

A common-mode choke (CMC) filters CM noise on the MDI. It is important to reduce CM noise as much as possible, since it can disrupt a PHY’s receiver. Additionally, CM noise results in higher radiated emissions since it is a single-ended energy source. Table 4 lists the requirements that a CMC must meet for use with a 100BASE-T1 PHY.

DC isolation

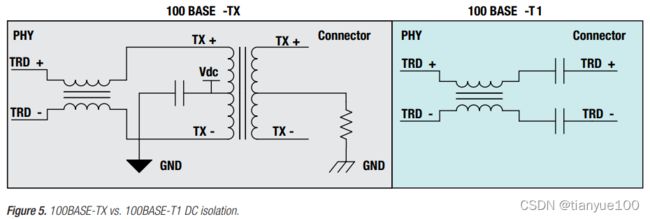

Figure 5 shows how to achieve DC isolation for both 100BASE-TX and 100BASE-T1.

100BASE-TX PHYs typically use transformers with the center tap (on the PHY side) tied to a DC voltage dependent on the PHY. The transformers also use Bob Smith termination (center tap, on the connector side, tied to ground through a resistor) to help improve CM noise filtering [12].

100BASE-T1 takes a simpler approach by using just two capacitors. The two capacitors provide DC isolation and reduce solution size compared to an application with a transformer. Figure 6 shows a typical 100BASE-T1 circuit implementation.

For more information about a 100BASE-T1 design implementation, see the Automotive StandAlone Gateway Reference Design with Ethernet and CAN. This reference design implements TI’s DP83TC811R-Q1 100BASE-T1 PHY in a typical automotive gateway application, with all selected circuit components for the design based on the 100BASE-T1 standard.

Conclusion

100BASE-T1 is the first automotive-specific Ethernet standard to meet the needs of vehicle networking. It builds on lessons learned from 10BASE-T, 100BASE-TX and 1000BASE-T to meet strict automotive emissions requirements, cabling weight, cost and footprint size. For more information, see the Solutions – Schematic, Layout and BOM Examples for Various Applications featuring TI’s DP83TC811S-Q1.

OEMs will inevitably decide how and where to implement 100BASE-T1 in their vehicles. But in the end, 100BASE-T1 is a gateway technology that facilitates the adoption of in-vehicle networking enabling further development of automotive systems.

References

1. C.M. Kozierok, C. Correa, R. Boatright and J. Quesnell. Automotive Ethernet – The Definitive Guide. Intrepid Control Systems, 2014.

2. L. Bello. “The Case for Ethernet in Automotive Communications.” ACM SIGBED Review – Special Issue on the 10th International Workshop on Real-Time Networks (RTN 2011), Vol. 8, No. 4, pp. 7-15, 2011.

3. D.A. Abaye. “BroadR-Reach Technology: Enabling One Pair Ethernet.” Broadcom Corp., 2012.

4. D. Pannell. “Audio Video Bridging (AVB) Assumptions IEEE 802.1 AVB Plenary.” IEEE 802.1 AVB, Stockholm, 2007.

5. “White Paper Blu-Ray Disc Format 2.B Audio Visual Application Format Specifications for BDROM.” Blu-Ray Disc Association, 2005.

6. A. Aaron and D. Ronca. “High Quality Video Encoding At Scale.” techblog.netflix.com, 2015.

7. “DVD Forum White Paper HD DVD Format Overview.” DVD Forum, 2007.

8. R. Bielby. “ADAS Camera Requirements – Driving Memory Needs.” Micron, 2017.

9. “IEEE Standard for Ethernet Amendment 1: Physical Layer Specifications and Management Parameters for 100Mbps Operation over a Single Balanced Twisted Pair Cable (100BASE-T1).” IEEE Standard 802.3bw, pp. 39-63, 2015.

10. “IEEE 100BASE-T1 (Formerly OABR).” Vector Informatik GmbH, Oct. 19, 2016. [Online]. Available: https://elearning.vector.com/index.php?&wbt_ ls_seite_id=1588373&root=378422&seite=vl_ automotive_ethernet_introduction_en. [Accessed March 7, 2018].

11. R.J. Barry, E.A. Lee and D.G. Messershmitt. Digital Communication. Norwell, Massachusetts: Kluwer Academic Publishers Group, 2004.

12. “ENT-AN0098 Application Note Magnetics Guide.” Microsemi, Aliso Viejo, California: 2016.

13. M. Sauerwald. “CAN Bus, Ethernet, or FPD-Link: Which is Best for Automotive Communications?” Texas Instruments Analog Applications Journal SLYT560, 2014.