3线模拟SPI驱动 HX8347 TFT屏

老五家2.8寸屏,3线GPIO模拟SPI驱动

前言

面对没有定义的屏幕应该如何应对?查丝印吗?屏幕的驱动芯片都小的惊人,想必是不会打上丝印的,所以即使用显微镜观察,也不能直接看到芯片的类型。没有资料的屏幕,应该只能人工从几百个引脚中判断哪个是哪个,进而推断芯片类型,想想就晕。 但大佬们都太厉害了,看看FPC就知道屏幕的接线定义,也许还有其他巧妙的办法吧。一直好奇这种神技是怎么练成的,也尝试自己来猜定义,但发现实在太难,还是拿来主义,做个等等党(等着引脚定义)比较靠谱。

![]()

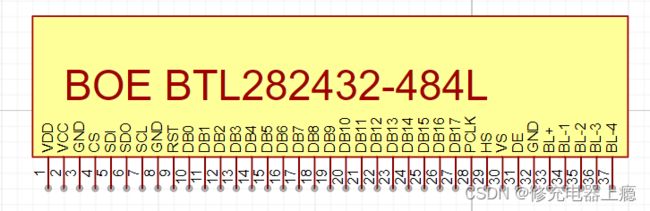

本文用的屏是2.8寸TFT屏,驱动芯片是HX8347,定义早被大佬分析出来:

定义有了。但不巧[IM3~0]=1100,只能支持3线SPI+RGB。驱动RGB屏不是单片机的强项。好像STM32F7XX和ESP32 S3是支持RGB,但也只是好像,这两个都价格不菲,手头也没有。

还是想办法用3线SPI来驱动吧。

一、源码

HX8347.h

#ifndef USER_HX8347_H_

#define USER_HX8347_H_

#define X_MAX_PIXEL 240

#define Y_MAX_PIXEL 320

#define RED 0xf800

#define GREEN 0x07e0

#define BLUE 0x001f

#define WHITE 0xffff

#define BLACK 0x0000

#define YELLOW 0xFFE0

#define GRAY0 0xEF7D //灰色0 3165 00110 001011 00101

#define GRAY1 0x8410 //灰色1 00000 000000 00000

#define GRAY2 0x4208 //灰色2 1111111111011111

#define LCD_CS GPIO_Pin_0 // CS:PA0

#define LCD_SDA GPIO_Pin_1 // SDA:PA1

#define LCD_SCL GPIO_Pin_3 // SCL:PA3

#define LCD_RST GPIO_Pin_4 // RST:PA4

#define LCD_SCL_SET GPIO_WriteBit(GPIOA, LCD_SCL,Bit_SET)

#define LCD_SDA_SET GPIO_WriteBit(GPIOA, LCD_SDA,Bit_SET)

#define LCD_CS_SET GPIO_WriteBit(GPIOA, LCD_CS,Bit_SET)

#define LCD_RST_SET GPIO_WriteBit(GPIOA, LCD_RST,Bit_SET)

#define LCD_SCL_CLR GPIO_WriteBit(GPIOA, LCD_SCL,Bit_RESET)

#define LCD_SDA_CLR GPIO_WriteBit(GPIOA, LCD_SDA,Bit_RESET)

#define LCD_CS_CLR GPIO_WriteBit(GPIOA, LCD_CS,Bit_RESET)

#define LCD_RST_CLR GPIO_WriteBit(GPIOA, LCD_RST,Bit_RESET)

void LCD_GPIO_Init(void);

void Lcd_WriteIndex(unsigned char Index);

void Lcd_WriteData(unsigned char Data);

void LCD_WriteData_16Bit(unsigned int Data);

void Lcd_Write_REG(unsigned char Index,unsigned char Data);

void LCD_Init(void);

void Lcd_Clear(unsigned int Color);

void FillRect(u16 x1, u16 y1, u16 x2, u16 y2, u16 color);

#endif /* USER_HX8347_H_ */

HX8347.c

#include "debug.h"

#include "HX8347.h"

void LCD_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure = {0};

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

GPIO_InitStructure.GPIO_Pin = LCD_SCL|LCD_SDA|LCD_CS|LCD_RST;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

}

//向SPI总线传输一个8位数据

void SPI_WriteData(unsigned char Data)

{

unsigned char i=0;

for(i=8;i>0;i--)

{

if(Data&0x80)

LCD_SDA_SET; //输出数据

else LCD_SDA_CLR;

LCD_SCL_CLR;

LCD_SCL_SET;

Data<<=1;

}

}

//向液晶屏写一个8位指令

void Lcd_WriteIndex(unsigned char Index)

{

//SPI 写命令时序开始

LCD_CS_CLR;

SPI_WriteData(0x70);

SPI_WriteData(Index);

LCD_CS_SET;

}

//向液晶屏写一个8位数据

void Lcd_WriteData(unsigned char Data)

{

LCD_CS_CLR;

SPI_WriteData(0x72);

SPI_WriteData(Data);

LCD_CS_SET;

}

//向液晶屏写一个16位数据

void LCD_WriteData_16Bit(unsigned int Data)

{

LCD_CS_CLR;

SPI_WriteData(0x72);

SPI_WriteData(Data>>8);

SPI_WriteData(Data);

LCD_CS_SET;

}

void Lcd_Write_REG(unsigned char Index,unsigned char Data)

{

Lcd_WriteIndex(Index);

Lcd_WriteData(Data);

}

void Lcd_Reset(void)

{

unsigned int i;

LCD_RST_CLR;

Delay_Ms(50);

LCD_RST_SET;

Delay_Ms(50);

}

// set region to paint

void LCD_SetWindow(unsigned int x1,unsigned int y1,unsigned int x2,unsigned int y2)

{

//SC

Lcd_Write_REG(0x02,x1>>8); // Column address start2

Lcd_Write_REG(0x03,(u8)x1); // Column address start1

//EC

Lcd_Write_REG(0x04,x2>>8); // Column address end2

Lcd_Write_REG(0x05,(u8)x2); // Column address end1

//SP

Lcd_Write_REG(0x06,y1>>8); // Row address start2

Lcd_Write_REG(0x07,(u8)y1); // Row address start1

//EP

Lcd_Write_REG(0x08,y2>>8); // Row address end2

Lcd_Write_REG(0x09,(u8)y2); // Row address end1

//写0x22到index register,那么下次send data就会直接被写到graphic ram

Lcd_WriteIndex(0x22);

}

void FillRect(u16 x1, u16 y1, u16 x2, u16 y2, u16 color)

{

LCD_SetWindow(x1, y1,x2,y2);

x2 = x2 - x1 + 1;

y2 = y2 - y1 + 1;

for(x1 = x2; x1 != 0 ; x1--)

{

for (y1 = y2;y1 != 0 ;y1--)

{

LCD_WriteData_16Bit(color);

}

}

}

void LCD_Init(void)

{

LCD_GPIO_Init();

Lcd_Reset();

Lcd_Write_REG(0x18,0x88); //UADJ 75Hz

Lcd_Write_REG(0x19,0x01); //OSC_EN='1', start Osc

//Power Voltage Setting

Lcd_Write_REG(0x1B,0x1E); //VRH=4.60V

Lcd_Write_REG(0x1C,0x07); //AP Crosstalk 04

Lcd_Write_REG(0x1A,0x01); //BT (VGH~15V,VGL~-10V,DDVDH~5V)

Lcd_Write_REG(0x24,0x38); //VMH 27

Lcd_Write_REG(0x25,0x5F); //VML

//VCOM offset

Lcd_Write_REG(0x23,0x8C); //for Flicker adjust

Lcd_Write_REG(0x1F,0x88);// GAS=1, VOMG=00, PON=0, DK=1, XDK=0, DVDH_TRI=0, STB=0

Delay_Ms(5);

Lcd_Write_REG(0x1F,0x80);// GAS=1, VOMG=00, PON=0, DK=0, XDK=0, DVDH_TRI=0, STB=0

Delay_Ms(5);

Lcd_Write_REG(0x1F,0x90);// GAS=1, VOMG=00, PON=1, DK=0, XDK=0, DVDH_TRI=0, STB=0

Delay_Ms(5);

Lcd_Write_REG(0x1F,0xD0);// GAS=1, VOMG=10, PON=1, DK=0, XDK=0, DDVDH_TRI=0, STB=0

Delay_Ms(5);

//Display ON Setting

Lcd_Write_REG(0x28,0x38); //GON=1, DTE=1, D=1000

Delay_Ms(40);

Lcd_Write_REG(0x28,0x3C); //GON=1, DTE=1, D=1100

Lcd_Write_REG(0x36,0x09); //REV, BGR

Lcd_Write_REG(0x17,0x05); //16BIT/PIXEL

//Gamma 2.2 Setting

Lcd_Write_REG(0x40,0x00); //

Lcd_Write_REG(0x41,0x00); //

Lcd_Write_REG(0x42,0x00); //

Lcd_Write_REG(0x43,0x11); //

Lcd_Write_REG(0x44,0x0e); //

Lcd_Write_REG(0x45,0x23); //

Lcd_Write_REG(0x46,0x08); //

Lcd_Write_REG(0x47,0x53); //

Lcd_Write_REG(0x48,0x03); //

Lcd_Write_REG(0x49,0x11); //

Lcd_Write_REG(0x4A,0x18); //

Lcd_Write_REG(0x4B,0x1a); //

Lcd_Write_REG(0x4C,0x16); //

Lcd_Write_REG(0x50,0x1c); //

Lcd_Write_REG(0x51,0x31); //

Lcd_Write_REG(0x52,0x2e); //

Lcd_Write_REG(0x53,0x3f); //

Lcd_Write_REG(0x54,0x3f); //

Lcd_Write_REG(0x55,0x3f); //

Lcd_Write_REG(0x56,0x2c); //

Lcd_Write_REG(0x57,0x77); //

Lcd_Write_REG(0x58,0x09); //

Lcd_Write_REG(0x59,0x05); //

Lcd_Write_REG(0x5A,0x07); //

Lcd_Write_REG(0x5B,0x0e); //

Lcd_Write_REG(0x5C,0x1c); //

Lcd_Write_REG(0x5D,0x88); //

Delay_Ms(100);

FillRect(0, 160, 239, 239, 0xf800 );

}

二、说明

1、LCD初始化是从GITHUB上拷的一段程序,具体是啥意思我也不清楚。试过官方数据手册里的初始化程序,一直不能成功。

2、写寄存器的程序

void Lcd_WriteIndex(unsigned char Index)

{

LCD_CS_CLR;

SPI_WriteData(0x70);

SPI_WriteData(Index);

LCD_CS_SET;

}

3、写数据的程序

void Lcd_WriteData(unsigned char Data)

{

LCD_CS_CLR;

SPI_WriteData(0x72);

SPI_WriteData(Data);LCD_CS_SET;

}

上面程序中出现SPI_WriteData(0x70); SPI_WriteData(0x72);统一解释下:

因为是3线SPI,所以缺少CD(或RS)引线,解决的办法一般是SPI发送数据时第一个bit的值代表CD。这样因为多出了1bit,就需要处理9bit的数据。UC1601就是这样,但是HX8347不是这样。

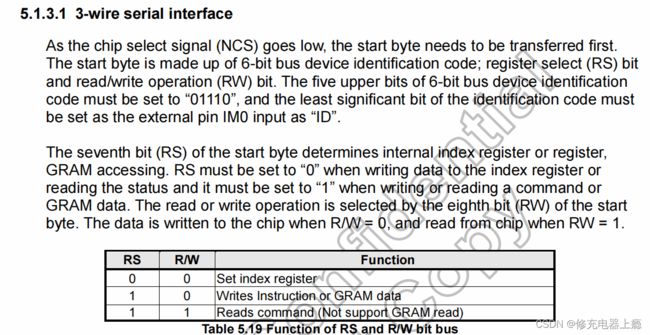

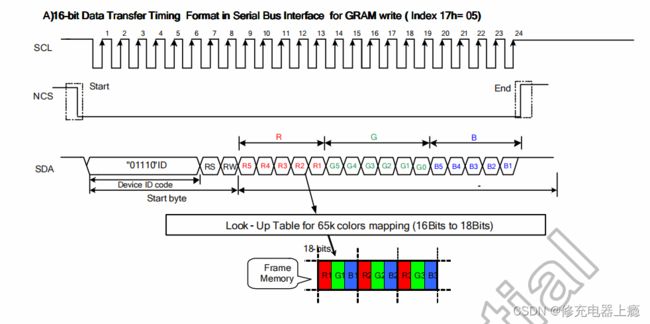

下面摘自HX8347的数据手册:

大概意思就是在发数据前需要发“01110”[ID][RS][RW],一共是8bit。

这里ID应该取0。RS取0是写指令,取1是写数据。RW取0,表示写。

所以写指令就是:01110000=0x70;写数据就是:01110010=0x72。也因此就有了:

SPI_WriteData(0x70); SPI_WriteData(0x72);

三、总结

1、主控是沁恒家申请的CH32V307的评估板,开发工具是MounRiver。不得不说评估板和开发工具都很完美。评估板留有arduino接口,可以和arduino扩展板链接。MounRiver编译很快,下载烧录更快,基本都是零点几秒。

2、本源码可以直接添加到CH32V307的demo中CH32V307EVT\EVT\EXAM\GPIO\GPIO_Toggle例程中运行。

int main(void)

{

NVIC_PriorityGroupConfig(NVIC_PriorityGroup_2);

SystemCoreClockUpdate();

Delay_Init();

LCD_Init();

while(1)

{

Delay_Ms(1000);

FillRect(0, 0, 239, 319, 0x07c0 );

Delay_Ms(1000);

FillRect(0, 0, 239, 319, 0x0030 );

Delay_Ms(1000);

FillRect(0, 0, 239, 319, 0x0000 );

Delay_Ms(1000);

FillRect(0, 0, 239, 319, 0xf800 );

}

}

3、用的是软件模拟3线SPI,所以帧数很低。以后考虑硬件SPI,或再加DMA,但DMA需要SRAM太大,可能玩不转。

演示用视频