BSCM

Basic of Supply Chain Management

Session 4: Material Requirements Planning 物料需求计划

Purpose 目标

Material requirements planning (MRP) is the bridge between master planning and production in the factory. This session addresses the basic concepts of the MRP process, which relies on the use of planning application software to support a set of business processes for the day-to-day management of the priority plan. MRP has two major business functions:

物料需求计划(MRP)是工厂主计划与生产之间的桥梁。本课讨论MRP流程的基本概念,该流程依赖于使用规划应用软件来支持一组业务流程,用于优先计划的日常管理。MRP有两个主要的业务功能:

Base on the master production schedule (MPS) quantities and due dates for end items, create a time-phased plan that determines what components are needed to make a product and when. This is called a priority plan for order releases and receipts for materials purchased from suppliers and manufacturers of components, or subassemblies, and end items by the factory.

根据主生产计划(MPS)数量和成品的交期,制定一个时间阶段计划,确定生产产品所需的组件以及生产时间。这被称为订单发布以及从零部件供应商和制造商购买的材料接收的优先计划。Maintain and adjust the priority plan to account for changes in customer orders and forecasts, material shortages, and production problems.

维护和调整优先计划,以适应客户订单和预测的变化、材料短缺以及生产问题。

Learning Objectives 学习目标

-

Material Requirements Planning Environment 物料需求计划环境

Explain the role of dependent versus independent demand in MRP.

解释依赖需求与独立需求在MRP中的作用。Describe the relationship between MRP and three other functions in the manufacturing planning and control (MPC) hierarchy.

描述MRP与制造计划与控制(MPC)层次中其他三个功能之间的关系。

-

Bill of Material 材料清单

Define parent and component in the bill of material (BOM), and explain their relationship.

在《物料清单》(BOM)中定义母公司和子公司,并解释它们之间的关系。Perform a simple BOM explosion.

进行一次简单的BOM爆炸。Explain the use of the planning bill.

解释计划单的用途。Differentiate between where-used reports and pegging reports.

区分何处使用报告和跟踪报告。

-

Material Requirements Planning Logic 物料需求计划逻辑

List four major inputs to MRP.

列出MRP的四个主要输入。Describe the role of lead-time offsetting and exploring in creating the priority plan.

描述在制定优先计划时,前置时间的逆推和探索的作用。Explain the origin of the gross requirements in an MRP record.

在MRP记录中解释总需求的来源。Calculate the net requirements for the end item and components.

计算成品和组件的净需求。Offset a planned order release from a planned order receipt.

从计划订单接收(时间)逆推计划订单发出(时间)。

-

Using and Managing the Priority Plan 使用和管理优先计划

Differentiate between a scheduled receipt and a planned order receipt.

区分预定接收和计划订单接收。Differentiate between an open order, a planned order, and a firm planned order.

区分公开订单、计划订单和确定计划订单。Explain the role of MRP software in the release of planned orders and managing the priority plan.

说明MRP软件在计划订单发布和优先计划管理中的作用。List the events of following the release of a planned order.

列出计划订单发布后的事件。List at least two techniques that can be used to maintain component and end-item due dates in the priority plan.

列出至少两种可以在优先计划中维护组件和成品的技术。

Material Requirements Planning Environment 材料需求计划环境

In this section we will address the underlying concepts of MRP:

在本节中,我们将讨论MRP的基本概念:

- nature of demand 需求的性质

- linkages to other manufacturing planning and control functions 与其他生产计划和控制职能的联系

- MRP objectives MRP的目标

- inputs to MRP MRP的输入

Nature of Demand 需求的性质

From an MPC standpoint, there are two types of demand: independent demand and dependent demand.

从MPC的观点来看,有两种需求:独立需求和依赖需求。

The table shown in Visual 4-6 is an independent demand item, where demand for the item is independent of any other demand. The decision on how many tables to make depends on either a forecast, customer orders, or both. The components of the table, however, are dependent demand items.

在图4-6中显示的桌子是一个独立的需求项,其中对该项目的需求与任何其他需求无关。决定要制作多少桌子取决于预测、客户订单或两者一起。然而,该桌子的组件是相互依赖的需求项。

All end items, such as the table, have a BOM -- which we will soon discuss in more detail -- that lists the description and quantity of all of its components. Once the forecast or order quantity is known, MRP calculates the number of all the components required. The demand for components is dependent on the demand for the table.

所有成品(如表)都有一个BOM(我们将很快详细讨论),它列出了所有组件的描述和数量。一旦知道了预测或订单数量,MRP就会计算所需的所有组件的数量。对组件的需求取决于对该桌子的需求。

Linkages with Other Manufacturing Planning and Control Functions 与其他制造计划和控制功能的联系

MRP is the last of the priority planning levels. It is directly linked to three other MPC functions:

MRP是最后一个优先规划级别。它与其他三种MPC功能直接相连:

-

Master scheduling: The MPS establishes specific end-item due dates and quantities. MRP is the component planner. It calculates a time-phased priority plan. This plan consists of (1) order release and receipt dates for the purchase and manufacture of components and (2) the final assembly operation. MRP determines the materials and quantities needed to make a product and when.

主计划:MPS建立特定的成品交期和数量。MRP是组件计划者。它计算一个分阶段的优先计划。本计划包括:(1)为采购和制造零部件而发出的订单和收货日期,以及(2)最后的组装操作。MRP决定生产产品所需的材料和数量。

-

Capacity requirements planning (CRP): The MRP is valid only if there is sufficient production capacity when it is needed. The check against capacity availability is called CRP.

产能需求计划(CRP): MRP只有在有足够生产能力时才有效。对产能可用性的检查称为CRP。

-

Production activity control (PAC): MRP is the input to PAC. It plans the release and receipt dates for orders, but it is the responsibility of purchasing and PAC to implement and control the orders.

生产活动控制(PAC): MRP是PAC的输入,计划订单的发布和收货日期,采购和PAC负责订单的执行和控制。

Objectives of MRP MRP的目标

What does MRP do? It has two major objectives: determine requirements and keep priorities.

MRP是干什么的?它有两个主要目标:确定需求和保持优先级。

-

Requirements -- MRP determines requirements by addressing the following questions:

需求——MRP通过解决以下问题确定需求:What components are required to manufacture an end item? Some of these will need to be purchased, some already are in inventory, and some will be made as part of the end-item production process.

制造最终产品需要哪些部件?其中一些需要采购,一些已经在库存中,一些将作为最终产品生产过程的一部分。What quantity of each component will be required?

每个组件需要多少数量?When will orders be released and received for (1) purchased components from suppliers and (2) for components that will be manufactured or assembled during the production process?

1)从供应商处购买的组件,以及(2)在生产过程中制造或组装的组件,何时发出和接收订单?

-

Priorities -- The order and release dates for purchased and manufactured components listed above constitute the priority plan, but MRP is affected by unplanned events such as changes in the demand, shortages of production capacity, late arrival or completion of components, and excessive scrap. Material planners keep the priority plan current in the face of changing customer sales orders and due dates by actions that include the following:

优先级——上述采购和制造部件的订单和发布日期构成优先级计划,但MRP受到需求变化、产能短缺、组件迟交或延迟完工、过度报废等意外事件的影响。在客户销售订单和到期日不断变化的情况下,物料计划员通过以下行动保持优先计划的有效性:

Expediting or de-expediting work orders -- also called shop orders or manufacturing orders -- or purchase orders.

加快或取消加快工作订单——也称为车间订单或制造订单——或采购订单。Changing work orders or purchase orders, such as quantities and due dates

更改工作订单或采购订单,例如数量和到期日Adding or canceling work orders or purchase orders

增加或取消工作订单或采购订单

MRP Process Inputs and Outputs MRP过程的输入和输出

Inputs 输入

There are four major data inputs to the MRP process, as shown in the table below.

MRP过程有四个主要的数据输入,如下表所示。

| Source | Data | Description |

|---|---|---|

| MPS | Planned and scheduled orders for end items 计划和排程的成品订单 | End-item quantities 成品数量 End-item due dates 成品交期 |

| Product structure file 产品结构文件 | BOMs | Components required 所需组件 Quantity of each component per parent 每个父组件的数量 |

| Inventory record file 库存记录文件 | Inventory status 库存状态 | Component and end-item quantities on hand 组件和成品的在手数量 Component and end-item quantities allocated 组件和成品的已分配数量 Component and end-item quantities on order 组件和成品的预订数量 |

| Item master file 物料主文件 | Planning factors 计划因子 | Lot size 批量大小 Lead time 交货时间 Yield and scrap factors 产量和废品因子 Safety stock 安全库存 |

Outputs 输出

The section on the MRP logic will cover outputs in some detail. MRP creates a priority plan consisting of planned order receipts and releases. Planners, with the support of MRP software, release planned orders that authorize the following:

MRP逻辑部分将详细介绍输出。MRP创建一个优先计划,包括计划订单收据和交付。计划人员在MRP软件的支持下,发布计划订单,授权如下:

the release of purchase orders to suppliers

向供应商发出采购订单the release of manufacturing orders, or shop orders, to the factory

向工厂发出制造订单或车间订单

Planning Software

Because of the volume and complexity of calculations, most companies rely on application software for MRP. Software applications are a lot faster and more accurate in performing MRP calculations needed to create the priority plan. Example of such calculations are:

由于计算量和复杂性,大多数公司都依赖于MRP的应用软件。软件应用程序在执行创建优先计划所需的MRP计算时要快得多,也更精确。这种计算的例子:

Exploding BOMs for determining an end item's component quantities, down to the component and raw material level

展开BOM用于确定成品的组件数量,直至组件和原材料水平Checking inventory records for quantities on hand, on order, or allocated

检查库存记录,在手数量、在订数量或分配数量Offsetting order release and receipt dates for net component and raw material requirements from the end-item due dates, which will be covered later in this section.

从成品到期日期对净部件和原材料需求的订单发布和收货日期进行补偿(偏移),本节稍后将对此进行讨论。

In addition, MRP software keeps track of due dates in the priority plan and the status of materials and production. It also

此外,MRP软件在优先计划中跟踪到期日以及材料和生产的状态。它还

advises planners on when to release planned orders

建议计划人员何时发出计划订单advises when to expedite or take other actions on maintain the due dates in the priority plan

建议何时加快或采取其他行动,以维持优先计划内的到期日replans MRP on a periodic basic to update material requirements, due dates, and inventory status.

重新计划MRP,定期更新物料需求,到期日和库存状态。

Bill of Material 物料清单

Introduction

bill of material (BOM) -- A listing of all the subassemblies,

intermediates, parts, and raw materials that go into a parent

assembly showing the quantity of each required to make an assembly.

所有组成父组件的部件、中间体、零件和原材料的清单,显示每个组件所需的数量。

-- APICS Dictionary

The authors of Introduction to Materials Management,7th ed. (Arnold et al.), state that the BOM is one of the most important documents in a manufacturing company. They refer to it as the major building block of MRP. BOM data on the raw materials and components needed to produce end items are critical inputs to MRP. Variants of the BOM include recipes for baked goods and formulas for chemicals.

《物料管理导论》(Introduction to Materials Management,第7版)的作者Arnold等指出,BOM是制造企业中最重要的文件之一。他们称其为MRP的主要组成部分。生产最终产品所需的原材料和部件的BOM数据是MRP的关键输入。BOM的变体包括烘焙食品的配方和化学配方。

Summarized BOM and the Indented Bill 汇总物料清单和多级物料清单

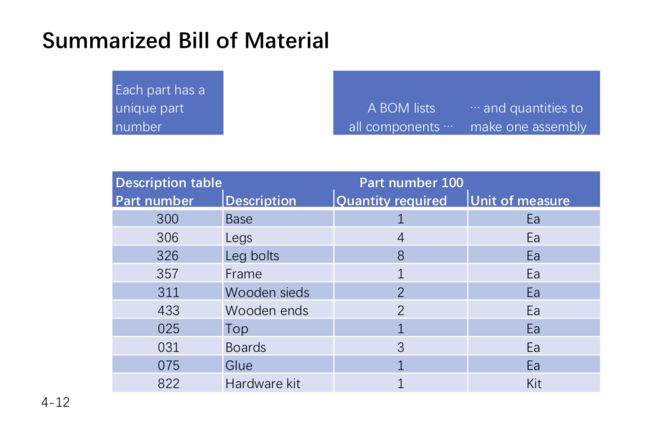

The BOM usually is presented in list form. Visual 4-12 is an example of a summarized BOM, which is a list of all the components in an assembly. For each component, a bill shows a unique part number, a description, the quantity needed in the assembly of its parent, and the unit of measure.

BOM通常以列表的形式出现。图4-12是汇总BOM的一个示例,BOM是配件中所有组件的列表。对于每个组件,清单显示了唯一的部件号、描述、其父组件组装所需的数量和度量单位。

The indented bill in Visual 4-13 is more commonly used and gives an indication of an assembly or end-item product structure. Note the part-number indentation showing that table 100 actually consists of two subassemblies: base 300 and top 025, and a hardware kit 822. The latter is a purchased component because the bill does not show components going into it during production; therefore it is not made by the manufacturer and has to originate with a supplier.

在图4-13中多级物料清单更常用,并给出了配件或最终产品结构的指示。注意部分编号缩进显示表100实际上由两个组件组成:底座300和顶025和硬件套件822。后者是购买的组件,因为账单上没有显示在生产过程中进入的组件;因此,它不是由制造商制造的,必须由供应商发起。

Base 300 and top 025, as subassemblies, consist of other components. The components of base 300 include legs 306, leg bolts 326, and frame 357. The latter is a subassembly made up of wooden sides 311 and wooden ends 433.

底座300和顶025,作为子件,包括其他组件。底座300的组件包括底座306、底座螺栓326和骨架357。后者是一个子件,由木边311和木端433组成。

What components in the indented bill, in addition to hardware kit 822, are purchased components?

除了硬件套件822外,在多级清单中有哪些部件是购买的?

How many assemblies/subassemblies are in the bill?

清单里有多少个配件/子件?

With respect to quantities, let's use as an example legs 306 that go into base 300. One unit of base 300 requires four legs 306. Note that the unit of measure is EA(each), so that the quantity required would be 4*1 = 4. If the unit of measure were one dozen, table 100 would be an unconventional 48-legged table.

关于数量,让我们以底座300中的腿306为例。底座300的一个单位需要四条腿306。注意,度量单位是EA(每个),因此所需的数量是4*1 = 4。如果以一打为单位,那么桌子100将是一张非常规的48条腿的桌子。

Note: In practice, glue might often be purchased as an operating supply item and not be included in the BOM. Tracking the specific amount of glue actually used could be impractical. This practice enables the costs to be included as part of the overhead.

注:在实际操作中,胶水可能经常作为操作供应品购买,而不包括在BOM中。跟踪实际使用的胶水的具体数量可能不切实际。这种做法使成本成为经常费用的一部分。

Single-Level BOM 单级BOM

This visual shows the BOM in what is called a product tree format to facilitate learning and understanding.

这张图展示了BOM的产品树格式,便于学习和理解。

We mentioned earlier that the APICS Dictionary definition refers to the BOM as a listing of all components that go into making an assembly. The visual illustrates that a BOM for an end item such as table 100 actually is made up of several single-level bills for its assemblies.

我们在前面提到过,APICS词典定义将BOM作为组成配件的所有组件的列表。这幅图说明,桌子100等成品的BOM实际上是由其配件的几个单层清单组成的。

At the top of the visual is a single-level bill for table 100. The bill shows table 100 as the parent and right below it are components needed for its final assembly. We pointed out earlier that two of the components -- base 300 and top 025 -- also are assemblies, but because they are components of another assembly (table 100), they are called subassemblies. The third components is hardware kit 822 consisting of purchased hardware specific to table 100.

在图的顶部是桌子100的单级清单。该清单显示了桌子100作为父组件,下面是其最终组装所需的组件。我们在前面指出,其中两个组件——底座300和桌面025——也是配件,但由于它们是另一个配件(桌子100)的组件,它们被称为子配件。第三个组件是硬件工具包822,由购买的特定于桌子100的硬件组成。

Multilevel BOM 多级BOM

If you examine the multilevel BOM for table 100, you should be able to see that it actually is made up of two subassemblies and the final assembly. The point is that end items usually consist of several logical groupings of components, or assemblies, based on the way the product is assembled.

如果您检查桌子100的多级BOM,您应该能够看到它实际上是由两个子件和最终配件组成的。关键是,成品通常由基于产品组装方式的几个逻辑组件组或配件组成。

The multilevel BOM for an end item such as table 100 is an example of the grouping of single-level BOMs for the subassemblies that go into it.

像桌子100这种成品的多级BOM是加入它的子件的单级BOM的分组示例。

It is important to note that BOM applications software stores information for each assembly and subassembly as a separate and unique single-level bill. When BOM data for table 100 are needed for MRP purposes, the BOM application will assemble the single-level bills for all of the assemblies into a multilevel bill for table 100. The subassembly single-level bills can be used for any end item that requires them.

需要注意的是,BOM应用软件将每个配件和子件的信息存储为单独的、唯一的单级清单。当MRP需要桌子100的BOM数据时,BOM应用程序将所有配件的单级清单组装为桌子100的多级清单。子件单级清单可以用于任何需要它们的成品。

Parent-Component Relationship 父组件关系

We have alluded to the parent-component relationship is single-level BOMs. The multilevel bill illustrates the fact that subassemblies and purchased components are components of the assemblies that they go into, but they also are parents of the subassemblies and purchased components that go into them.

我们已经提到了父组件关系是单级BOM(组成的)。多级清单说明了一个事实,即子件和外购件是他们进入的配件的组件,但他们也是子件和外购件的父组件。

BOM: Summary 总结

These are the key points about the BOM:

BOM要点如下:

All manufactured end items have a BOM.

所有制成品都有BOM。An end item usually has a multilevel bill consisting of two or more single-level bills.

一个成品通常都有一个多级清单,由两个或更多单级清单组成。All single-level bills consist of a parent and components below it.

所有单级清单都包含一个父级和若干下级组件。For each subassembly made by the manufacturer and not purchased from a supplier, there also will be a single-level bill.

每个子件由制造商制成而不是从供应商采购,也会有一个单级清单。The parent in a subassembly single-level bill also is a component of a final assembly or subassembly.

子件单级清单中的父级组件也是最终配件或子件的组件。If a part has no other parts going into it on the BOM, then it is assumed to be a purchased part.

如果一个零件在BOM上没有其他零件进入,那么它就被认为是一个外购的零件。

In summary: 总之

A multilevel BOM is a collection of single-level bills.

多级BOM是单级清单的集合。A subassembly parent also can be a component of an assembly or another subassembly.

子件的父组件也可以是配件或另一个子件的组件。If a component has no other components going into it, it cannot be a subassembly and therefore is an item purchased from a supplier.

如果一个组件没有其他组件进入,它就不能是一个子件,因此是从供应商购得的组件。

Planning Bill 计划单

A BOM lists the components necessary to build an end product. A planning bill, on the other hand, plans material requirements for a family of end products for which there are several variations based on options for one or more components.

BOM列出了构建最终产品所必需的组件。另一方面,计划单则计划一系列最终产品的材料需求,这些产品根据一个或多个组件的选项有多种变化。

Take the example of a bicycle, which has several options for three main components.

以自行车为例,它有三种主要部件可供选择。

| Component | Number of options |

|---|---|

| Color (paint) | 3 |

| Wheel size | 3 |

| Frame (male/female) | 2 |

| Common parts | 1 |

The company takes 18 different variations which these components options (332 = 18), each with its own BOM to maintain. The planning bill simplifies the 18 bills by showing, on one bill, the percentage split -- totaling 100 percent -- for each of the three components based on a forecast or historical usage data.

公司采用18种不同的组件选项(332 = 18),每个组件都有自己的BOM来维护。计划单简化了18个清单,在一个清单上显示了基于预测或历史使用数据的三个组件的百分比分割(总计100%)。

The planning bill in this case represents the average bicycle. It does not represent a buildable product but is used to simplify forecasting, MPS, and MRP. If 10,000 bicycles were forecasted, you could calculate the number for each of the 18 variations to plan for and ultimately make and ship to distributors. For example, if 10,000 bicycles were forecasted, you would order and stock 2,500 small, 5,000 medium, and 2,500 large-size frames and use the same reasoning for ordering colors and wheels. These the can be assembled when orders come in.

在这种情况下,计划单表示的是普通自行车。它并不表示可构建的产品,而是用于简化预测、MPS和MRP。如果预测了10000辆自行车,那么您就可以计算出这18种车型中每一种的计划数量,并最终将它们生产出来并交付给分销商。例如,如果预测有1万辆自行车,您将订购2500辆小型、5000辆中型和2500辆大型车架,并使用相同的推理来订购颜色和车轮。当订单进来时即可装配。

Where-Used and Pegging Data 用途和资料溯源

Where-Used

Where-used data are used in where-used reports. A where-used report is an inversion of a BOM information.

用途数据用于用途报告。用途报告是BOM信息的倒置。

A BOM lists the components of a parent item.

BOM列出父项的组件。A where-used report lists all of the items, or parents, in which a component is used whether or not there is a demand for the parent.

用途报告列出了使用组件的所有项目或父组件,不管是否需要父组件。Data may be single level (traced to the immediate parent) or full level (traced to the end-item parent).

数据可以是单个级别(追溯到直接父级)或完整级别(追溯到最终项父级)。

Where-used information has the following uses:

用途信息有以下作用:

identifying the parent items affected by an engineering change and assessing the impact of the change

确定受工程变更影响的父项,并评估变更的影响assessing the aggregate impact of costing changes for a component

评估组件成本变动的整体影响assessing the effects of component scarcity

评估组件稀缺性的影响assessing the benefits and costs of standardizing similar components, preventing storekeeping unit proliferation

评估标准化类似组件的好处和成本,防止库存单位的扩散

Pegging 溯源

A pegging report is similar to a where-used report except that it shows only those parents for which there is an existing requirements. These parents are currently in the priority plan and might be affected by a delay in the delivery of a component. The pegging report shows the following:

溯源报告类似于用途报告,只是它只显示已存在需求的父项。这些父项目前正处于优先计划中,可能会受到组件交付延迟的影响。

溯源报告展示如下:

the parents creating demand for components 父项创建组件的需求

the quantities required 所需数量

when those quantities are required 何时需要这些数量

where-used logic to identify current sources of demand 用于确定当前需求来源的用途逻辑

may be single level or multilevel 可为单层或多层

Uses of the BOM

BOM的使用

There are many uses for the BOM, starting as early as the design stage of a product and continuing through the various stages of the product management cycle: engineering change control, MRP, order management, manufacturing, service and repair, and cost accounting. This places a premium on a accuracy and being up-to-date, as errors in the bills can have broad ripple effects.

BOM有许多用途,从产品的设计阶段开始,一直持续到产品管理周期的各个阶段:工程变更控制、MRP、订单管理、制造、服务和维修,以及成本核算。这就很看重准确性和最新性,因为清单上的错误可能会产生广泛的连锁反应。

| Type of use | Description of use |

|---|---|

| Product definition | The BOM specifies the components needed to make the product. Product definition first occurs early in the product design process as product and process design engineers discover the best way to design and make a product. BOM指定生产产品所需的组件。产品定义首先出现在产品设计过程的早期,因为产品和过程设计工程师发现了设计和制造产品的最佳方法。 |

| Engineering change control | Product design engineers use the BOM to document changes made in the design of a product and the components used. The recording and control of changes to the product and the BOM are absolutely essential. 产品设计工程师使用BOM记录产品设计和使用的组件的变更。记录和控制对产品和BOM的更改是绝对必要的。 |

| Planning | The BOM is used by material planners to identify the materials that have to be scheduled to make an end product and what components have to be purchased or made to satisfy the MPS. BOM是物料计划人员用来确定生产成品所需的物料,以及为了满足MPS需要采购或制造哪些部件的物料。 |

| Customer service | Customer service uses BOMs when configuring make-to-order products during order entry. 客户服务在订单录入期间配置按订单生产的产品时使用BOM。 |

| Manufacturing | The BOM lists the parts needed to make or assemble a product. BOM列出了制造或组装产品所需的零件。 |

| Service and repair | The BOM determines the replacement parts necessary to repair a broken assembly. BOM确定修理损坏了的配件所必需的更换部件。 |

| Costing | Cost accounting uses the BOM to determine the quantity of direct materials consumed in making specific products. 成本核算使用BOM来确定在生产特定产品时直接消耗的材料数量。 |

Resource : Introduction to Materials Management,7th ed.,Amold et al., p.70

Material Requirements Planning Logic 物料需求计划逻辑

Approach to this Section

In this section, we are going to learn about the mechanics, or logic, that MRP uses to develop the priority plan.

在本节中,我们将学习MRP用于开发优先计划的机制或逻辑。

We will explain the MRP logic that creates the priority plan through

我们将解释创建优先计划的MRP逻辑

exploding and offsetting requirements 需求展开和补偿

calculating gross and net requirements 计算毛需求和净需求

This will bring us to the point in the planning process where a developed priority shows the time-phased dates and quantities for planned order releases and receipts for both purchased components (or purchase orders) and manufactured components (or manufacturing orders).

这将使我们在计划过程中到达这样一个点:一个已开发的优先级显示计划订单发布的分阶段日期和数量,以及采购组件(或采购订单)和制造组件(或制造订单)的收货分阶段日期和数量。

In the next section, we will address the basics of using and putting the material requirements plan into action.

在下一节中,我们将讨论使用和将物料需求计划付诸实施的基础知识。

MRP Logic Overview

MRP逻辑概述

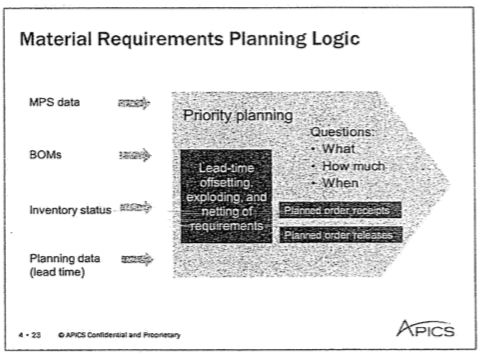

As discussed earlier and as summarized in Visual 4-23, the MRP process uses key inputs to determine and end item's required components (what); the quantities of those components (how much); and a time-phased plan (when) for the operations that will convert the end item into a finished product.

正如前面所讨论的和在图4-23中总结的,MRP过程使用关键输入来确定和结束项目所需的组件(什么);这些分量的数量(多少);以及将最终产品转换为成品的操作的分阶段计划(何时)。

This time-phased plan, or priority plan, expresses the necessary actions in the form of planned order releases and receipts. At the appropriate time, the planned orders are released; this authorizes purchase orders to be released to suppliers for materials and manufacturing orders to the factory.

这一分阶段计划或优先计划以计划订单发布和接收的形式表达了必要的行动。在适当的时间,计划的订单被发布;这就授权将采购订单发放给供应商,提供给工厂的材料和制造订单。

Lead-Time Offsetting and Exploding 提前期补偿和展开

To create a priority plan, MRP uses a process called lead-time offsetting and exploding. Three of the important components are

为了创建一个优先计划,MRP使用了一个叫做“提前期补偿和展开”的过程。它有三个重要的组成部分:

- lead time, or the time it takes to make a subassembly or component or receive delivery of a purchased component. Manufacturing lead-time data are found in the item master record.

提前期,或制造一个子件或组件或接收购买的组件交付所花费的时间。生产准备时间数据可以在项目主记录中找到。

- offsetting, which is the process of determining when a planned order release is needed in advance of the planned order receipt date of the item.

提前期补偿,即在计划订单收到日期之前确定何时需要计划订单发布的过程。

- exploding, which is the process of determining the total of each component needed for a parent.

展开需求,这是确定一个父组件所需的每个组件的总数的过程。

Below is the procedure for offsetting and exploding the planned order releases for D.

下面是对D的已计划订单发布进行补偿和展开的过程。

Offsetting 补偿

Visual 4-25 illustrates the offset procedure for parent B and its purchased component, D.

图4-25演示了父组件B及其购买组件D的补偿过程。

- Parent B has a lead time of 1 week. Its planned order receipt date is the beginning of week 5, so a planned order release for B must be offset to the beginning of week 4.

B的交货期为一周。它计划的订单收货日期是第5周期初,所以B的已计划订单发布必须被补偿到第4周期初。

- Parent B is an assembly of components C and D. This means planned order receipts for these components need to be available at the beginning of week 4, as they are needed when the planned order release of B occurs.

B是组件C和D的组装,这意味着这些组件的计划订单接收量需要在第4周开始时提供,因为当B的已计划订单发布时需要这些接收量。

- Because the lead time for D is 1 week, a planned order release needs to be scheduled for the beginning of week 3 to meet the week 4 due date.

因为D的交货期是1周,所以计划的订单发布需要安排在第3周的开始,以满足第4周的到期日。

Exploding 展开

Exploding, also called BOM explosion, is the process of multiplying a parent item's need for components based on the BOM. We already have covered this in the section on the BOM in Problem 4.1. We'll briefly illustrate this with the visual.

展开,也叫BOM分解,是一个基于BOM的父项对组件的需求倍增的过程。我们已经在问题4.1的BOM部分讨论过了。我们将用图像简单地说明这一点。

- Each parent in the BOM requires one unit of a component. Because the requirement for end-item parent B is 50 units and because D is a component of B, there is a requirement for 50 Ds in order to make 50 units of B. A single B requires 1 C, so the requirement for C = 1 * 50 units = 50 units.

BOM中的每个父组件都需要一个组件的单位。因为父组件要求最终产品B是50单位因为D是B的一个组成部分,就有50个D的需求,为了组成50单位的B。1个B需要1个C,所以需要50个单位的C。

- The requirement for parent B of 50 units is in week 5. This means the planned order receipt for B is at the beginning of business on the first day of week 5.

B的需求为在第5周需要50个单元。这意味着B计划的订单收货时间是在第5周的第一天业务一开始的时候。

Conclusion 结论

- A planned order release for D has been offset by one week from a planned order receipt due in week 4 per the lead-time information from the item master record.

D的计划订单发布已被项目主记录中每个提前期信息从第4周到期的计划订单接收中抵消一周。

- The planned order release quantity was exploded, per the assumed BOM requirement that one unit of parent B requires one unit of D, so 50 units of B require 50 units of D.

计划的订单发布数量被分解,根据假设的BOM需求,一个单位的父B需要一个单位的D,所以50个单位的B需要50个单位的D。

How many Ds would have to be ordered if the week 5 requirement for B was 100 units and the required quantity of D per parent item B was two units?

如果第5周B的需求量是100个单位,而每项B的需求量是2个单位,那么需要订购多少个D?

Gross and Net Requirements 毛需求和净需求

The next step in the MRP calculation logic is the determination of gross and net requirements. In previous exercises, we assumed that if a parent B has a component requirement of 50 Ds, you would need to schedule a receipt of 50 units of D, offset by the appropriate lead time.

MRP计算逻辑的下一步是确定毛需求和净需求。在之前的练习中,我们假设如果父组件 B的组件需求是50个D,那么您需要安排50个单位的D的收货,用适当的提前期来补偿。

If you have items in inventory, they must be taken into account and subtracted from the gross requirement to determine a net requirement. This also is called gross to net, or netting.

如果你有存货项目,它们必须被考虑并且从总需求中减去以确定净需求。这也被称为粗到净,或净额计算。

Recognizing Available Inventory 识别可用库存

The convention is that the projected available inventory shown in a period represents the period-ending inventory. This means it is available at the very beginning of the next period.

约定在一个期间内所列的预计可动用存货就是期末存货。这意味着它可以在下一个时期开始时使用。

To relate this to the visual, look at the 20 units of projected available shown for B in week 4. This is the week 4 end-of-period inventory that is available during week 5.

与图联系起来,看看第4周B的20个单位。这是第4周期末库存,在第5周可用。

Note that the inventory available in week 1 for end item B (20) and component C (10) are shown in the cells before week 1 to indicate that they were the on-hand inventory at the end of the period that preceded week 1.

请注意,第1周结束项目B(20)和组件C(10)的库存在第1周之前的单元格中显示,以表明它们是第1周之前期末的库存。

What is the inventory available during week 3 for component C?

C的可用库存在第三周有多少?

Calculation of Net Requirements

The following summarizes the process for determining net requirements. Refer to the visual.

下面总结了确定净需求的过程。如图。

-

Find the gross requirement for an end item, such as B (50 units), which is determined by the MPS. It is shown in and is available at the beginning of week 5.

查找最终项目的总需求,例如由MPS决定的B(50个单位)。它显示在第5周的开始。

-

Refer to the equation for net requirements, which is as follows:

净需求公式如下:Net requirements = gross requirements - available inventory 净需求=总需求-可用库存 Based on the MRP record shown in the visual, the net requirement for B in period 5 is 30.

根据图提供的MRP记录,第5期B的净需求为30。A receipt of 30 then is planned based on lot-size policy.

然后根据批次策略,计划收到30件。

What is the net requirement for component C in week 4?

第4周C组件的净需求是多少?

Component Availability and Offsetting 组件可用性和偏移量

Gross requirements, net requirements, and planned order receipts are considered to be available at the beginning of the week in which they are displayed.

毛需求、净需求和计划订单收货被认为是在显示它们的那一周开始时可用的。

For example, the gross and net requirements of end item D are shown in week 4, so a planned order receipt for D is shown in week 4 and is expected to be available at the beginning of the week. A planned order release for D is shown in week 3, based on a one-week lead time.

例如,最终项目D的毛需求和净需求在第4周显示,所以D的计划订单收货在第4周显示,预计在本周初可以收到。D的计划订单发出在第3周,基于一周的交付时间。

Basic MRP Record 基本的MRP记录

Salient Features 显著特性

Up until this point, we have not taken the time to discuss the salient features and terminology pertaining to a typical MRP record. There is one for every component of an end item, including the end item itself.

到目前为止,我们还没有花时间讨论与典型MRP记录相关的显著特性和术语。每个组件都有一个最终产品项,包括最终产品项本身。

If there were a time stamp on this record, it would be at the beginning of week 1.

如果这条记录上有一个时间戳,那应该是在第一周的开始。Week 1 is the action bucket, though no actions are necessary because there are no scheduled receipts or planned order releases; however, when week 3 rolls to week 1, there is the need for a planned order release.

第1周是action bucket,尽管没有必要进行操作,因为没有计划的接收量或已计划的订单发布;然而,当第3周转到第1周时,就需要一个计划订单发布。The lead time establishes the offset of the planned order release from the planned order receipt.

交货期确定计划订单发布与计划订单接收之间的偏移量。The top row shows time periods, called time buckets -- or weeks, in this example.

顶部一行显示了时间段,在本例中称为时间桶——或星期。The number of periods in the record is called the planning horizon; it should be as long as the cumulative lead time, which is equal to longest lead time among all the BOM paths below the end item.

记录中的周期数称为规划视界;它应该与累积的交付时间一样长,这等于在最终产品项之下的所有BOM路径中最长的交付时间。An item is available at the beginning of the time bucket in which it is required.

一个项目在需要它的时间桶的期初即可用。The quantity shown in the projected available row is the projected available balance at the end of the period; all other quantities are for the beginning of the period.

预计可用行中显示的数量是在期末时预计可用余额;所有其他的量都是期初。

Scheduled Receipts 计划接收量

The example shown above adds yet another row of data called scheduled receipts.

上面的示例添加了另一行数据,称为计划接收量。

Scheduled receipts are planned orders that, before week 1, already have been released or placed with suppliers and the factory and have receipt dates within the planning horizon.

计划接收量是指在第1周之前已经发出或与供应商和工厂一起下单并在计划期限内收到的计划订单。These orders are called open orders.

这些订单称为公开订单。In periods in which there are scheduled receipts, their quantities are added to the projected available balance. (See the addition of 20 units of scheduled receipts to projected available in week 2.) Eventually the quantities influence the gross to net requirements calculation.

在有计划接收量的期间,其数量将加到预计可用量中。(请参阅第2周预计可获得的20份计划接收量。)最终数量影响总量和净需求量的计算。The new formula for net requirements = gross requirements - scheduled receipts - projected available.

净需求量的新公式 = 总需求量 - 计划接收量 - 预计可用量。

Class Problem 4.5:

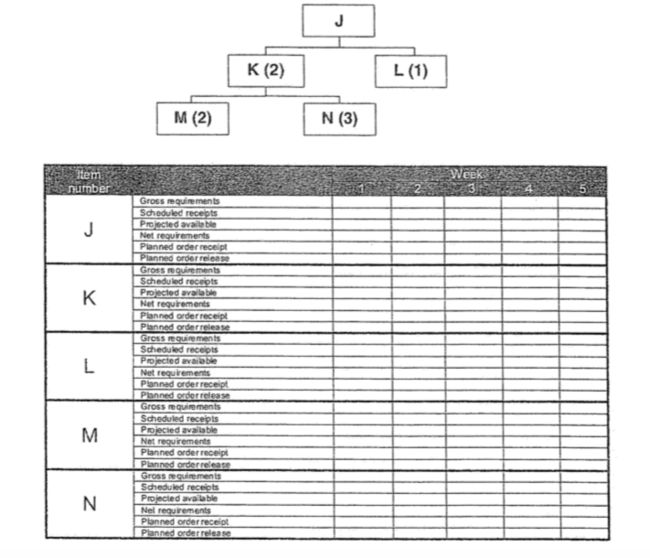

Given the following product tree BOM, explode, offset, and calculate the gross and net requirements. All lead times are one week except for K, where the lead time is two weeks. The component quantities per parent are shown in parentheses and the lot-size policy is as required. The MPS calls for completion of 50 Js in week 5. There is a scheduled receipt of 47 Ks in week 2. There are 85 Ls and 135 Ns on hand.

给定以下产品树BOM,分解,补偿,并计算总需求和净需求。所有的交货期都是一周,除了K,交货期是两周。每个父组件的数量在括号中显示,并且根据需要使用批量策略。MPS要求在第5周完成50个J。计划在第二周收到47个k。目前有85个L和135个N。

Capacity Requirements Planning 能力需求计划

In master scheduling, rough-cut capacity planning (RCCP) is used to check the MPS against available capacity. In MRP, another capacity check is performed -- this time focusing on resources available to meet due dates in the priority plan at the component level as opposed to the end-item level.

在主调度中,粗能力计划(RCCP)用于根据可用产能检查MPS。在MRP中,执行另一个产能检查——这次集中于可用于满足优先计划中组件级别而不是最终项目级别的到期日期的资源。

This will be addressed in Session 5: Capacity Management and Production Activity Control.

这将在第五课上讨论:能力管理和生产活动控制。

Using and Managing the Priority Plan 使用和管理优先计划

Role of MRP Software MRP软件的角色

MRP software applications are used in most manufacturing companies and also are used in non-manufacturing industries such as retail, distribution, and service. They perform two major functions:

MRP软件应用程序在大多数制造企业中都使用,也在零售、分销和服务等非制造行业中使用。它们有两个主要功能:

-

Perform gross to net, lead-time offset, and explosion calculations.

Given an end-item due date from the MPS, MRP software can perform the gross to net, offsetting, and explosion calculations necessary to create the priority plan for end items and their components. It does these fast, accurately, and in very high volumes.执行总到净、前置时间补偿和分解计算。

给定MPS的最终产品项到期日,MRP软件可以执行为最终产品项及其组件创建优先计划所必需的总到净、补偿和分解计算。它可以快速、准确地且大量地完成这些任务。 -

Create action and exception messages.

Action and exception messages are critical to planners in managing the priority plan. MRP software is integrated with inventory and other systems. The software also keeps track of due dates in the priority plan and the status of materials and production. For example, it issues action messages when a planned order becomes due for release, or tools into the action bucket; it issues exception messages when material availability is not sufficient to meet a planned order receipt date for a component or an end item.创建操作和异常消息。

操作和异常消息对于计划人员管理优先计划至关重要。MRP软件与库存和其他系统集成。该软件还在优先计划中跟踪到期日以及材料和生产状况。例如,当计划的订单到期交付时,或者工具进入操作桶时,它会发出操作消息;当材料可用性不足以满足组件或最终产品项的计划订单接收日期时,它会发出异常消息。

It is important to note that MRP software is not normally programmed to release planned orders. That is the role of the planner. On the basis of action and exception messages, the planner will release planned orders, expedite or de-expedite component schedules, or change order quantities.

需要注意的是,MRP软件通常不会被编程来发布计划好的订单。那是计划者的角色。根据操作和异常消息,计划员将发布计划订单,加速或减速组件排程,或更改订单数量。

Order Control 订单控制

In managing the priority plan, the material planner works with three main types of orders as shown in the MRP record: planned orders, firm planned orders, and released orders -- or scheduled receipts.

在管理优先计划时,物料计划员要处理MRP记录中显示的三种主要订单类型:计划订单、已确认计划订单和已发出订单——或计划接收量。

Planned Orders 计划订单

Planned orders are created by planning software when it encounters net requirements. The net requirement generates planned order receipts in the system, and planned order releases appear in a prior period based on the lead-time offset. Note the planned order receipt of 5 units in week 3 and the planned order release in week 1.

计划订单是由计划软件在遇到净需求时创建的。净需求在系统中生成计划订单接收量,并且计划订单发布出现在前一个周期中,基于交付时间偏移量。请注意,计划在第3周收到5个单元的订单,计划在第1周发出订单。

Firm Planned Orders 已确认计划订单

A firm planned order is a tool that enables the planner to override the MRP logic. Note the firm planned order release of 35 units in week 2, three weeks instead of two before the planned order receipt. This could be the result of the planner's decision to allow another week of lead time for the receipt due in week 5, possibly because production has a temporary quality problem and requires another week.

已确认计划订单是一个工具,它使计划者能够覆盖MRP逻辑。请注意,公司计划在第2周发布35个单位的产品,在计划收到订单之前的三周而不是两周。这可能是由于计划员决定允许在第5周收货前再给一周的时间,可能是因为生产有暂时的质量问题,需要再给一周的时间。

Released Orders 已发出订单

Planners are responsible for releasing planned orders, aided by action messages from the MRP system. Once released, a planned order becomes on open order to the factory or supplier. It appears as a scheduled receipt of 20 units as in week 2 of the MRP record shown in the visual.

计划人员负责在MRP系统的行动信息的帮助下发布计划订单。一旦发出,计划的订单就会成为工厂或供应商的公开订单。它似乎是预定收到的20个单位,如图所示在第2周的MRP记录。

A released order also is under the control of the planner and is subject to expediting, de-expediting, change in order quantities, and even cancellation.

已发出的订单也在计划员的控制下,并可能发生加速、减速、变更订单数量甚至取消等情况。

In what week was the planned order released for the scheduled receipt for week 2?

第2周的计划接收量的计划订单在哪个星期发出?

What types of orders are under the control of the planner?

计划员控制哪些类型的订单?

Releasing Planned Orders 发出计划订单

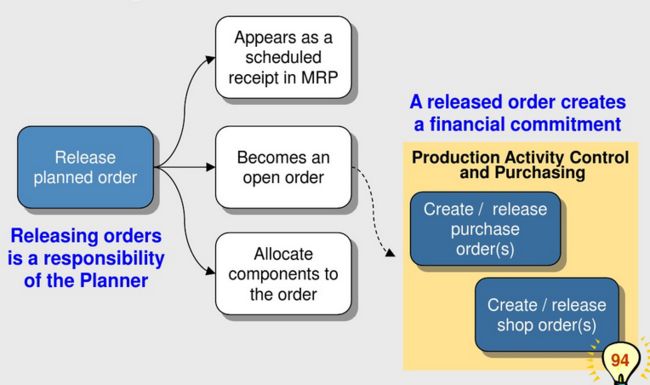

The release of an order by a planner, with assistance of the MRP application logic, ensures that work is done in time to meet net requirements.

计划员在MRP应用程序逻辑的帮助下发布订单,确保工作及时完成,以满足净需求。

As shown in the visual, the release of the order involves a number of events.

如图所示,订单的发布涉及到许多事件。

- Releasing a planned order 发布已计划好的订单

- Scheduling a receipt 安排接收

- Creating an open order 开单

- Allocating components to the order 分配组件到订单

Note that the open order is an authorization to:

- purchasing, to buy the necessary material, or to

- manufacturing, to make the component

注意,开单是授权:

- 采购或购买必要的物料或

- 制造物料以满足组件的制造

Maintaining Priorities and Replanning 维护优先级和重新计划

Releasing planned orders is only one of several responsibilities of the planner. The planner has the general responsibility of managing the current priority plan, such as planned orders, open orders, and end-item due dates. The planner also deals with the numerous events that might affect order priorities.

发布计划订单只是计划员的几个职责之一。计划员负责管理当前的优先计划,如计划订单、未完成订单和最终项目到期日。计划员还处理可能影响订单优先级的众多事件。

These include 这些包括

-

external events such as 外部事件如:

- changes to customer orders 客户订单变更

- supplier shortages 供应商短缺

- late deliveries and lower than required order quantities from suppliers 迟交及供应商低于所要求的订货数量

-

internal events such as 内部事件如:

- lower yields or higher scrap factors than planned 收益率低于计划或废品系数高于计划

- late or early open order completions 延迟或提前完成公开订单

- capacity or resource constraints 产能或资源限制

- material shortages caused by inventory record inaccuracies that hide shortages or surpluses of components or end items and lead to the need to expedite or de-expedite.

因库存记录不准确而造成的物料短缺,隐藏了零件或最终产品的短缺或过剩,导致需要加速或减速。

There basically are two sets of actions available to the planner:

计划员基本上有两套行动:

- Maintain the priority plan by taking actions to maintain the scheduled due dates for the production of components or the end item. These would include expediting or de-expediting.

通过采取行动维护零件或最终产品生产的预定到期日来维护优先计划。这将包括加速或减速。

- Replan the due date if an event does not enable the maintaining of a due date. Class Problem 4.6 illustrates the options available to the planner when the receipt of a component is less than planned and affects the schedule of not just one but two parent items that use the same component.

如果事件使得不能维护到期日期,则重新计划到期日期。问题4.6说明了当收到的组件比计划的少,并且影响了使用相同组件的两个父产品项(而不止一个)的进度时,计划员可以使用的选项。