CAN总线控制Robomodule驱动使底盘电机转动

材料 单片机、RoboModule、RM35电机

基本步骤:

本文以开环模式为例,主要讲述底盘电机驱动部分。

注意:

1)发送指令与模式选择指令,模式选择指令与发送数据指令之间要有延时函数。

2)连续发送的时间间隔不能小于 2 毫秒

注释:

1)该片代码一共配置了3个底盘电机。DIL、DIR、DB为电机ID

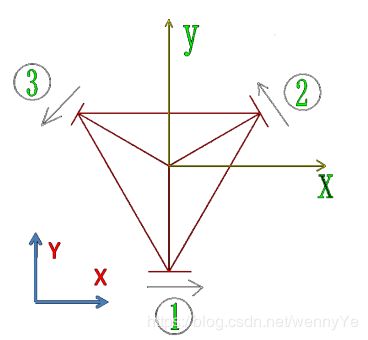

2)底盘电机图示:

3)底盘电机速度

应用代码:

void D_motor_Reset()//全部底盘电机循环体内部的初始化重配置(含延时)

{

CAN_RoboModule_DRV_Reset(DIL); //对DIL复位,下同

CAN_RoboModule_DRV_Reset(DIR);

CAN_RoboModule_DRV_Reset(DB);

delay_ms(1000); //发送复位指令后的延时必须要有,等待驱动器复位完毕。

CAN_RoboModule_DRV_Config(DIL,100,0); //配置为1s传回一次数据

CAN_RoboModule_DRV_Config(DIR,100,0);

CAN_RoboModule_DRV_Config(DB,100,0);

delay_ms(1);

CAN_RoboModule_DRV_Mode_Choice(DIL,OpenLoop_Mode); //选择进入模式

CAN_RoboModule_DRV_Mode_Choice(DIR,OpenLoop_Mode);

CAN_RoboModule_DRV_Mode_Choice(DB,OpenLoop_Mode);

delay_ms(1000); //发送模式选择指令后,要等待驱动器进入模式就绪。所以延时也不可以去掉。

}

void D_sport(short x,short y,short d,short s)

{

if(d==0) s=(-s);

CAN_RoboModule_DRV_OpenLoop_Mode(x,y,s);

}

#define PI 3.1415926f

int D_move(short s,short theta) //让车子以全速的(0.02x)%,角度(0.1*theta)%度移动.注意90度为前进

{

float Vx,Vy,v1,v2,v3;

Vx=cos(0.1*(float)theta*PI/180.0)*(float)s;

Vy=sin(0.1*(float)theta*PI/180.0)*(float)s;

#define AFA 60

v1 = (float)(-(cos(AFA / 180.0f*PI) * Vx) - (sin(AFA / 180.0f*3.1415926f) * Vy));

v2 = (float)Vx;

v3 = (float)(-(cos(AFA / 180.0f *PI) * Vx) + (sin(AFA / 180.0f*3.1415926f) * Vy));

D_sport(DILD,v1);

D_sport(DIRD,v3);

D_sport(DBD,v2);

}

下面为控制的主要函数:

void CAN_RoboModule_DRV_Reset(unsigned char Group,unsigned char Number)

{

unsigned short can_id = 0x000;

CanTxMsg tx_message;

tx_message.IDE = CAN_ID_STD; //标准帧

tx_message.RTR = CAN_RTR_DATA; //数据帧

tx_message.DLC = 0x08; //帧长度为8

if((Group<=7)&&(Number<=15))

{

can_id |= Group<<8;

can_id |= Number<<4;

}

else

{

return;

}

tx_message.StdId = can_id; //帧ID为传入参数的CAN_ID

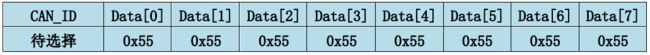

tx_message.Data[0] = 0x55;

tx_message.Data[1] = 0x55;

tx_message.Data[2] = 0x55;

tx_message.Data[3] = 0x55;

tx_message.Data[4] = 0x55;

tx_message.Data[5] = 0x55;

tx_message.Data[6] = 0x55;

tx_message.Data[7] = 0x55;

can_tx_success_flag = 0;

CAN_Transmit(CAN1,&tx_message);

while(can_tx_success_flag == 0); //如果CAN芯片是TJA1050,注释掉这个判断。

}

模式选择指令函数:

- OpenLoop_Mode_____________ 0x01

- Current_Mode _______________ 0x02

- Velocity_Mode _______________0x03

- Position_Mode _______________0x04

- Velocity_Position_Mode________ 0x05

- Current_Velocity_Mode_________0x06

- Current_Position_Mode_________0x07

- Current_Velocity_Position_Mode___0x08

void CAN_RoboModule_DRV_Mode_Choice(unsigned char Group,unsigned char Number,unsigned char Mode)

{

unsigned short can_id = 0x001;

CanTxMsg tx_message;

tx_message.IDE = CAN_ID_STD; //标准帧

tx_message.RTR = CAN_RTR_DATA; //数据帧

tx_message.DLC = 0x08; //帧长度为8

if((Group<=7)&&(Number<=15))

{

can_id |= Group<<8;

can_id |= Number<<4;

}

else

{

return;

}

tx_message.StdId = can_id; //帧ID为传入参数的CAN_ID

tx_message.Data[0] = Mode;

tx_message.Data[1] = 0x55;

tx_message.Data[2] = 0x55;

tx_message.Data[3] = 0x55;

tx_message.Data[4] = 0x55;

tx_message.Data[5] = 0x55;

tx_message.Data[6] = 0x55;

tx_message.Data[7] = 0x55;

can_tx_success_flag = 0;

CAN_Transmit(CAN1,&tx_message);

while(can_tx_success_flag == 0); //如果CAN芯片是TJA1050,注释掉这个判断。

}

开环模式下的数据指令函数:

void CAN_RoboModule_DRV_OpenLoop_Mode(unsigned char Group,unsigned char Number,short Temp_PWM)

{

unsigned short can_id = 0x002;

CanTxMsg tx_message;

tx_message.IDE = CAN_ID_STD; //标准帧

tx_message.RTR = CAN_RTR_DATA; //数据帧

tx_message.DLC = 0x08; //帧长度为8

if((Group<=7)&&(Number<=15))

{

can_id |= Group<<8;

can_id |= Number<<4;

}

else

{

return;

}

tx_message.StdId = can_id; //帧ID为传入参数的CAN_ID

if(Temp_PWM > 5000)

{

Temp_PWM = 5000;

}

else if(Temp_PWM < -5000)

{

Temp_PWM = -5000;

}

tx_message.Data[0] = (unsigned char)((Temp_PWM>>8)&0xff);

tx_message.Data[1] = (unsigned char)(Temp_PWM&0xff);

tx_message.Data[2] = 0x55;

tx_message.Data[3] = 0x55;

tx_message.Data[4] = 0x55;

tx_message.Data[5] = 0x55;

tx_message.Data[6] = 0x55;

tx_message.Data[7] = 0x55;

can_tx_success_flag = 0;

CAN_Transmit(CAN1,&tx_message);

while(can_tx_success_flag == 0); //如果CAN芯片是TJA1050,注释掉这个判断。

}

参考资料:11-RoboModule-RMDS系列驱动器-CAN总线通信协议说明