Fiber-reinforced polymer composites for Structural Applications: Electric vehicles applications

Abstract

This paper studies the application of fiber-reinforced polymer composites applicated on electric vehicles. It first discusses the situation of electric vehicles’ market and the features of fiber-reinforced composites, and then focuses on the different properties and the use of three most investigated fiber-reinforced polymers which are carbon fiber, glass fiber and natural fiber in the automotive industry. Carbon fiber has the most promising future application for its strength properties though the cost is still high. Glass fiber is widely used especially in the field of interiors and extoriors while in terms of sustainable development, environmental awareness and cost reduction, there is a growing trend of the replacement of glass fiber by natural fiber.

Keywords

Electric vehicles, carbon fiber, glass fiber, natural fiber

1. Introduction

Internal combustion vehicle is the most popular method of transportation in the world while it causes a lot of problems like air pollution, decrease of fossil resource which is nonrenewable, potential threat of energy security, etc. According to a research, around 200 thousand deaths is related the air pollution caused by cars [13]. With the advancement of electric vehicle technology and the support of public policy to the field, the electric vehicle industry has been gaining development notably recent years because of their better performance in environmental protection and energy efficiency. Compared with 2017, the growth of salary of electric vehicles in China is 61.7% in 2018, with 125 million ones sold. Similarly, it has even raised 80% with around 0.36 million electric cars sold in the US in 2018 and 39% of them is Tesla Model 3. The biggest automotive manufacture giants attracted with this new trend, have already paid great attention to electrification. The Volkswagen Group declared that the 40% of their products will be electric cars to meet the emission regulation in 2030, which has already developed a successful electric model plate called MEB. BYD group has even sold 0.52 million electric cars in 2018.

However, the change of energy model calls for the demand of different material for structural application which can still satisfy the requirement of economy, safety and power. In the aspect of vehicle composite materials, the most widely applied are fiber-reinforced polymers. Utilizing fiber-reinforced polymer composites to replace traditional metallic material to make electric vehicles lighter and stronger is nowadays becoming an appealing topic. For example, with the same battery capacity it can increase the mileage of the car while with the same mileage, vehicles can load fewer battery modules which means less weight and lower price. With the sophisticate choose of composites, the electric automotive can meet the requirement of strength, weight-reduction and durability.

2.Characteristics of Electric Vehicles

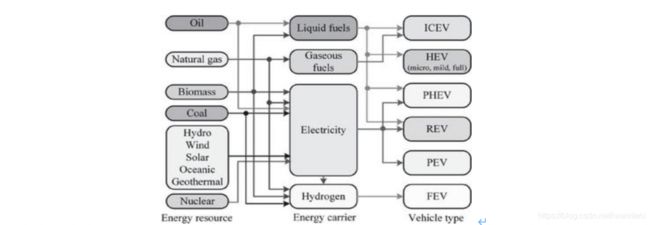

Compared with different versions of the definition of electric vehicle, the most popular one divides it into several detailed tails, which are electric vehicles (EVs), including pure electric vehicle (PEV), hybrid electric vehicle (HEV), and fuel-cell electric vehicle (FEV) [1]. Compared with internal combustion engine vehicles, which depends highly on fossil fuels with the consequence of environmental pollution, the power of electric vehicles, called electricity, can be easily generated from many energy resources, many of which are sustainable energy or clean energy, such as nuclear power, hydropower and so on. Fig.1 shows the relation among energy source, carrier and vehicle type. Actually, electric vehicle is not a new invention and in the begin of 20th century, even around 38% [1] cars are electric. Recent years it is popular again with the effort of automobile manufacturers like BYD and Tesla.

Fig.1 Relation among energy source, carrier and vehicle type

3.Characteristics of Fiber-reinforced Polymer Composites

Composites are combined with 2 or more distinguish chemical stuff in the macroscopic scale and separated by distinct interface. One or more discontinuous phases (fibers) are embedded into a continuous phase (matrix) which make the material stronger. This is one of the typical descriptions of fiber-reinforced polymer composites [22]. Ordinary material always has cracks and defects due to the weakness of manufacturing process which lead to the poor performance in tensile strength. Fibers, however, are able to achieve much higher strength and stiffness with the tiny structural parameters which can avoid defects and usually plays the role of “reinforcement” in the view of composite materials. The material chosen for fiber usually are metals, polymers, glasses and ceramics and they influence the properties like density, strength and modulus of the origin materials. With properly designed, fiber-reinforced polymer composites can often gain a longer lifetimes and lower maintenance costs, and the performance usual depends on the choice of materials, the way of manufacture and the surrounding conditions [2]. Usually it has lower weight, higher corrosion resistance, higher fatigue strength and longer duration. They generally are combined with distinguished materials called fibers and matrix, sometimes even have notable difference compared with their constituents. For example, the thermoplastic polymers allow vehicles to be equipped with affordable structural components to replace traditional metal solutions [9]. The picture below shows the classification of composites.

Fig.2 Classification of composites

4.The Application of Fiber-reinforced Polymer Composites on Electric Vehicles

Fiber-reinforced polymer composites are famous for their good mechanical properties like stiffness, strength, anisotropy, durability and stability. Unfortunately, the cost of composites is sometimes higher, especially for carbon fibers. In fact, the glass-reinforced composites with polymer matrix (GFPR), which is very cheap and have good tensile strength and chemical resistance, dominate the composite application [4][5]. Of course, there are some weakness such as relatively high density, low fatigue resistance. Though it is under the popularity of glass fiber, carbon fiber wins more highlight in the future development, because they outperform in strength-weight ratio and stiffness-weight ratio. The fiber-reinforced polymer composites (CFPR) can vary from different types that the matrix material is usually Epoxy, polyurethane, polypropylene, nylon while fiber can be carbon-fiber, glass-fiber or natural-fiber. And there is another noticeable polymer composite called natural fiber-reinforced polymer composites (NFPR) which is a good substitute of glass fiber. The following part will discuss the utilization of fiber composites on electric vehicles.

4.1. The Main Advantages of the Application of Fiber-reinforced Polymer Composites

4.1.1. Reduce Weight

The most direct advantages for fiber-reinforced polymer composites are to improve the safety, speed and decrease the weight and price of electric vehicles. The statistical benefit can be concluded as the table below [8]. To achieve the goal of lightweight, there are 2 main methods which are to improve the structural design and the substitute of material. Composite materials provide a good choice to reduce weight but are still able to satisfy the strength demands. However, the design of vehicle is very sophisticated and to change the material, especially composites, is a good direction. For example, polymer materials can save 20-40% of total weight, which is particularly significant in the tendency of growing weight of a car in the past years. This problem is important for battery electric vehicle, which is usually 250~400kg heavier than ordinary cars with the increase of safety, comfort and function, and the weight of batteries of course [8]. Around 7% of gas economy will be saved for 10% drop in weight for traditional cars [3]. As for electric vehicle, the saved loads can be transformed to more battery weight, which means it can run a longer distance. According to the analysis of British materials Systems Laboratory (MSL), carbon fiber can reduce more than 52%. Compared with steel body of 367.9kg, CFPR body is only 172kg [18]. In order to save energy and improve the competition, using polymer composites is essential. Fig.3 shows a typical benefit of 10% drop in weight.

Fig.3 Effect of weight reduction

4.1.2. Strengthen Strength

Sometimes it is challengeable to satisfy the designed performance with traditional material while for reinforcement composites it is much easier. As is shown in the former parts, fiber-reinforced polymer composites (CFPR) actually have better performance than steel and aluminium. For instance, the tensile strength of CFPR is above 3500Mpa, 7~9 times larger than steel. The elastic tensile modulus varies from 230Gpa to 430Gpa which outperform steel as well. The weight ratio and strength ratio are 1.8 and 2000Mpa separately, while Q235 is only 59Mpa [6]. The table below show the properties of several different materials. Table.1 shows some actual value of different material.

Table.1 Comparison between reinforced composites and metal

Fiber, which is the primary constituent in a fiber-reinforced material, occupies the majority of volume fraction and the biggest percentage of load. Matrix usually fixes fibers in good position and offers a necessary protection to avoid the corrosion factors from the outer surroundings. In this case, fibers paly the main role for the mechanical features shown above. Admittedly, there must be other advantages like design flexibility, cost reduction, safety concern and so on which will be further discussed in the following section respectively.

4.2. The chosen material of fiber-reinforced polymer composites

Material selection is actually depending on a systematic analysis which is the first and one of the most significant issues for car modify [9]. The criteria including weight-lighting, economic efficiency, safety, durability, recyclability, consumers’ satisfaction, political regulations and so on, which make the selection very challengeable and strategic. For example, BMW even decided to diminish the utilize of carbon fiber with lightweight steels instead in newly designed cars in order to keep high profits after the big success of BMW i3 city and i8 hybrid, which modelled a passenger cell made completely of carbon fiber [10], so the use of polymer composites, especially carbon fiber still has many challenges to deal with. The following parts will discuss the three most popular and promising composites which are carbon fiber-reinforced polymer composites, glass fiber-reinforced polymer composites and natural fiber-reinforced polymer composites.

4.2.1. Carbon Fiber-reinforced Polymer Composites (CFPR)

Though the price of carbon fiber composites are relatively higher, but with the decreasing of manufacture cost and its good structural performance, they become the most appealing material in the field. According to the matrix material, carbon-fiber-reinforced polymer composites can be devided into three category [6], which are resin matrix, ceramic matrix (CMC) and metal matrix(MMC).

CFPR, or carbon fiber-reinforced polymer is a common name of fiber-reinforced polymer composites which are combined with carbon fiber and resin matrix [7]. Because of its good mechanical performance, it is more widely used recently. One of the advantages is that it has high tensile strength and modulus in most common material. It also has strong fatigue strength for it is hard for small crack to expand in the internal material. The figure is a comparison between CFRP and steel. Plus, the carbon fiber composites can better absorb energy in collision, which is around 4~5 times better than aluminum or steel [6] which can further guarantee the security of vehicle. It is also dimensionally stable and easy to mold so that it is easy to be utilized for the manufacture of large components like bumper [7].

Because of its strong strength, carbon fiber-reinforced composites are widely used in carrosserie or bearing structure. According to widely Internet search, this kind of material are used on outer panels like front and rear bumpers, engine hoods, bottom guards, spoilers and so on, because of the easy access to manufacture. Lamborghini AventadorLP700-4 uses CFPR for assembled body, only 145.5kg, while the engine cover with CFPR of GM Chevrolet Corvette Z06 only weights 9.3 kg [17]. Drive system is also able to be equipped with carbon-fiber. Porsche 911 Turbo GT use carbon fiber with ceramic matrix for brake disc. CFRP drive shaft is designed on Renault EspaceQuadra, Toyota Mark II, Audi A4/A8 Quattros [17].

(a) (b)

© (d)

Fig.4 Utilization of CFRP

(a)rear bumper (b)front bumper ©arm (d)drive shaft

As one of the most successful electric cars involving widespread use of carbon fiber, BMW i3 is worthy to discuss. The main body is bonded together with CFRP parts, which are made from liquid resin and carbon fibers in molding process with high temperature and pressure and followed with speeded up harden process [11]. The exterior plastic parts like door panels and bumpers, which are made in bonding via injection molding that molding and joining the outer skin and substructure at one time [11]. Besides reducing weight and design flexibility, using polymer composites for exterior parts can better ensure the safety of pedestrian, which is of the same importance as passengers’ safety. Plus, the offcuts are recycled for roof panel in the thought of sustainable development.

4.2.2. Glass Fiber-reinforced Polymer Composites (GFRP)

Glass fiber is a strong, light and stable material made from fine fibers of glass and usually categorised in E-glass, C-glass and S-glass, while the matrix can be both thermoset, maybe epoxy, or thermoplastic [22]. Compared with metal, it is very popular for its high strength, modulus and weight characteristic. In general, the popularity comes from its high cost performance ratio. But the cost of the excellent properties of GFRP is the difficulty of finding a suitable disposal method [23], which is easier for natural fiber composites analyzed later.

There are many important applications of GFRP. For example, safety is always the first priority of customers and automotive manufacturers always try their best to get five star in the assessment of Glass fiber polymer can be used as cardboard panels or bumper beams to ensure security and crashworthiness for it outperforms metals in crushing characteristics, which is lighter than metal and cheaper than carbon fiber, though is usually weaker than CFPR. Glass fiber composites are usually designed in the shape of tubes with a trigger at one end [12]. When car accident occurs while the load rises to a certain value, the composite tubes will collapse constantly to absorbed energy to ensure the safety of passengers. GFRP bumper beam is usually made from thermoplastic matrix with unidirectional continuous fiber layers for the benefit of appealing capacity of absorbing and sometimes the glass fiber can be mixed together with carbon fiber [14]. The mechanical properties of fiber and matrix is presented in the table below.

Table.2 Comparison among glass fiber, carbon fiber and PP

In order to strengthen the heat and impact resistance and balance weight and strength, the fiber fillers usually longer than 10 mm with woven structure [15]. GFRP also have many other applications. For example, tank support, which can hold and buffer the water tank, can be manufactured from glass fiber with polypropylene matrix (PP/GF) [19]. Best performance can be obtained when the mass fraction of GF is 40%.

Fig.5 3D model of tank support

4.2.3. Natural Fiber-reinforced Polymer Composites (NFRP)

One of the definitions of NF is the reinforcement derived from plants or other living creatures [21]. In terms of the environmental awareness for a better sustainably developed society, recycling natural fibers raises many meaningful efforts which can ease the waste problem and lower the cost of components in the favor of policy makers and customers. Actually, there is a growing tendency to replace GFRP with NFRP. This kind of composites usually have lower cost and density so that are usual used in decorations. For example, natural fibers, like hemp, flax, sisal, jute, kenaf and so on, combined with polypropylene and other resins, often applied on door and trunk liners [9]. Compared with glass fiber, it is even more competitive in automotive industry, like good thermal performance, low cost, low hardness, low density, good accessibility and so on. And with the adjustment of the combination of the components, compatibility and interface, it can develop more diversity with design freedom [16][24].

Because of the vast possible sources of NFRP, including animal fur and plant fibers, researchers usually go for the following step [16]: fiber analysis, matrix analysis and composite analysis, including physical, chemical, mechanical, environmental, biological, and thermal properties. The table below is a comparison of several NFRP and date palm fiber has the best performance according to the research.

Table.3 Comparison of several natural fiber

Another report shows that kenaf fiber composites can replace the role of GF-sheet molding compound on automotive panels [20]. In comparison, kenaf-NFRP can save 33.1% energy consumption and ease environmental burden for 22.8% with many other unmentioned ecological benefit [20].

The environmental advantage of easy to dispose is associated with the disadvantage of low decomposition temperature [24]. When it is above 200 Celsius degree, it will decomposite and emit unpleasant smell. And the connect between NF with matrix is usually weaker. So, the application of NFRP in electric vehicle is usually focus on interior parts, such as ceiling, seat, console, instrument panel. NFRP can also be the noise-reducing material. Hemp fiber, flax fiber, sisal fiber and date palm fiber have been applied on door inner protectors, trunk masks and insulators [25].

5. Conclusion and Future Work

The utilisation of polymer composites with fiber reinforcement has a bright future in automotive industry, especially for the popularity of electric cars. Higher strength and higher stiffness can be achieved compared with the row material while lower density and lower weight can be achieved compared with metal. In general, carbon fiber has the best mechanical properties which can be used for chassis and drive system. In order to reduce the cost of CFPR, many attempts can be tried. For the instance of PAN-based carbon fiber, PAN precursors can be cheaper with high-speed spinning technique [26]; carbon fiber can be made by polyolefin and renewable lignin of low price [27]. And using guanidine hydrochloride to modify a commercial textile-grade acrylic fiber can help prepare cheap carbon fiber [28]. Glass fiber will continue its application on vehicle exteriors and interiors, though natural fiber developed fast in the similar automotive parts. The investigation for enforcing chemical stability for natural fibers is also welcomed. There is a hopeful prediction that with the rise selling of electric vehicles, cheaper fiber-reinforced polymer composites with better mechanical performance will be applicated on more parts in the structure of car body.

References

[1] K. T. Chau., “Electric vehicle machines and drives : design, analysis and application”,in Singapore : IEEE Press, John Wiley & Sons Singapore Pte. Ltd . 2015

[2] R. A. Shenoi, Stuart S. J. Moy, Leonard Hollaway, “Advanced Polymer Composites for Structural Applications in Construction” pp33

[3] J. Njuguna,” Lightweight Composite Structures in Transport: Design, Manufacturing”

[4]J.Fan,J.Njuguna,”An introduction to lightweight composite materials and their use in transport structures”

[5] L.A.Khan, A.H.Mehmood, “Cost-effective composites manufacturing processes for automotive applications”

[6] ZY,Zhang, KY.Shao, Y.Gao, “The Analysis of the application of carbon-fiber polymer composite in pure electric vehicle”, doi:10.3969/j.issn.1007-4554

https://www.ixueshu.com/document/6880d4cbb106d1b5205f78368a63da86318947a18e7f9386.html

[7] Baojie.Zhang, “the application of carbon-fiber polymer composite in pure electric vehicle”

https://www.ixueshu.com/document/18debfaea2340c5d5a1599302c5a5f71318947a18e7f9386.html

[8] L.Y.Zhao, Y.B.Li, “The application of fiber polymer composite on new energy electric vehicle”

https://wenku.baidu.com/view/4f00f6bb6394dd88d0d233d4b14e852459fb3972.html?from=search

[9] M.P.Todoer, C.Bulei, I.Kiss, “An Overview on Fiber-Reinforced Composites Used in the Automotive Industry”, ISSN:1584-2665,1584-2673

[10] J.Shury, “BMW Limits Carbon Fibre Use to Increase Profits”, https://www.compositestoday.com/2016/10/bmw-limits-carbon-fibre-use-to-increase-profits/

[11]Z.peterson, “Building by Bonding: BMW, the i3 and Carbon Fiber”, ADEtP.

[12]G.Y.Fortin, E.A.Elbadry, H.Hamada, “Crashworthiness of cardboard panels reinforced with braided glass fiber rods for vehicle side impact protection”,Journal of Reinforced Plastics and Composites, December 2018, Vol.37(23), pp.1387-1401

[13] Caiazzo F, Ashok A, Waitz IA, et al. Air pollution and early deaths in the United States. Part I: quantifying the impact of major sectors in 2005. Atmos Environ 2013; 79: 198–208.

[14]D.H.Kim, H.G.Kim, H.S.Kim, “Design Optimization and Manufacture of Hybrid Glass/Carbon Fiber Reinforced Composite Bumper Beam for Automoble Vehicle”, Composite Structures.

[15] N.Ichinose, “Enhancement of accuracy of automotive crash analysis for plastic material parts”, Nippon Gomu Kyokaishi, 12, 2016, pp. 381–386.

[16] Faris M. AL-Oqla, S.M. Sapuan, “Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry ”, Journal of Cleaner Production.

[17] S.Huang, L.Wang, C.Chen, “Application and Prospect of Carbon Fiber Composite Material in the Automotive”, http://www.cmasteq.com.

https://www.ixueshu.com/document/16c147a8ae4f403840a4271b8bb45fdc318947a18e7f9386.html

[18] E.F.Horst, “Challenges of Materials Technology for Low Consumption Vehicle Concepts”, Advanced Engineering Materials.2003.5.

[19] X.M.Zhang, J.S.Li, “Structure Analysis and Performance Test of Auto Water Tank Supports Based on Polypropylene/Glass Fiber Composites”,ISSN:1001-9278.2017.07.016.

https://www.ixueshu.com/document/e9d0c5b740fa8306063f2c3400b05306318947a18e7f9386.html

[20] Y.J.Wu, C.L.Xia, L.P.Cai, A.C.Garcia, ‘”Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound ”, Journal of Cleaner Production.

[21] M Boopalan, M Niranjana, M J Umapathy. Composites: Part B 51, 2013, pp.54–57.

[22] M R Sanjay*, B Yogesha, “Studies on Natural/Glass Fiber Reinforced Polymer Hybrid Composites: An Evolution”, www.materialstoday.com/proceedings.

[23] S Harish, D Peter Michael, ABensely, D Mohan Lalb, A Rajadurai. Materials characterization: 60, 2009, pp.44-49.

[24] Q.Z.Lee, “Application and Research of Natural Plant Fiber Reinforced Plastics in the Automotive”, DOI:10.13520/j.caki.rpte.2016.04.023.

https://www.ixueshu.com/document/586c8b8cb957527ff1a01bbcf2be8300318947a18e7f9386.html

[25] G Thilagavathi, E.Pradeep, T.Kannaian, “Development of Natural Fiber Nonwovens for Application as Car Interiors for Noise Control”, Industrial Textiles, 2010,39(3):267-278.[26] Frank E, [26]Steudle LM, Ingildeev D, Buchmeiser MR. “Carbon fibers: precursor systems, processing, structure, and properties”. Angew Chem. 2014;53(21):5262–98.

[27] Baker DA, Gallego NC, Baker FS. “On the characterization and spinning of an organic-purified lignin toward the manufacture of low-cost carbon fiber”. J Appl Polym Sci. 2012;124(1):227–34.

[28] J.Huang, O.Y.Qin, M.L.li, F.F.Heng, H.B.Ma, Y.S.Chen, “Thermal behavior and thermal stabilization of guanidine hydrochloride-modified acrylic fiber for preparation of low-cost carbon fiber”, Journal of Thermal Analysis and Calorimetry (2019) 136:2195–2203