【车间调度】基于GA/PSO/SA/ACO/TS优化算法的车间调度比较(Matlab代码实现)

目录

1 概述

2 运行结果

2.1 标题2.1

2.2 main1运行结果

2.2 main2运行结果

3 Matlab代码

4 参考文献

| 电气代码 | 智能算法及其应用 |

| 路径规划 | 神经网络预测 |

| 优化调度 | 图像处理 |

| 车间调度 | 信号处理 |

| 浪漫的她 | 我的哲思 |

| 数学建模 | 完整代码事宜 |

1 概述

柔性作业车间调度问题(Flexible Job shop Sched-uling Problem , FJSP)是在离散制造业和流程工业中应用广泛的一类问题,已被证明是典型的 NP-上hard问题。

FJSP是作业车间调度问题(Job shop Scheduling Prob-lem,JSP)的扩展,FJSP中每个工件的每道工序均可以在可选择的有限台机器上加工,且在每台机器上的加工时间不一定相同,可灵活地进行资源选择,提高调度的敏捷性,更加贴近实际生产。目前元启发式算法是解决FJSP的常用方法,其主要可分为群体智能算法和局部搜索算法。陆家辉等人提出一种混合。

Jaya优化算法求解柔性作业车间调度问题,并设计一种离散化更新算子使Jaya 优化算法更适用于FJSP,混合2种新型邻域结构提高算法的同守儿→军等人[2将化学反应算法与禁忌搜索相结合,设计了4种操作来保证种群多样性,以实现最优的全局探索,加人禁忌搜索提高了混合算法的局部寻优能力。

详细讲解:车间调度专栏

2 运行结果

2.1 标题2.1

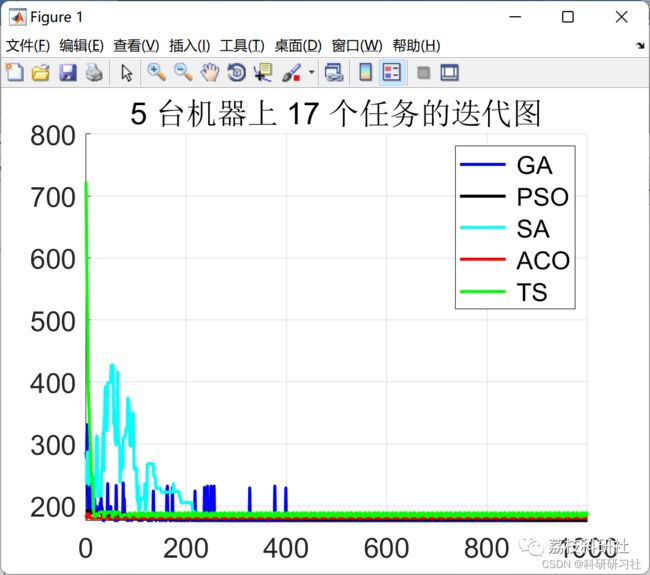

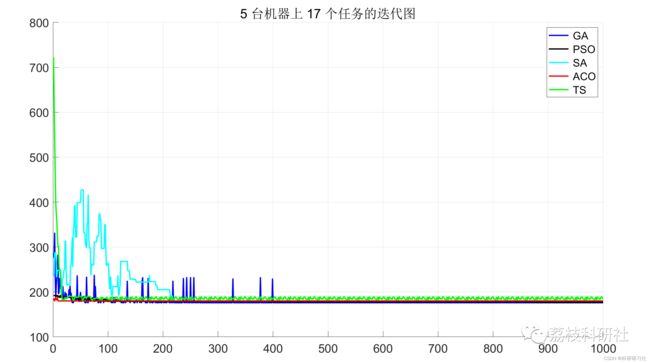

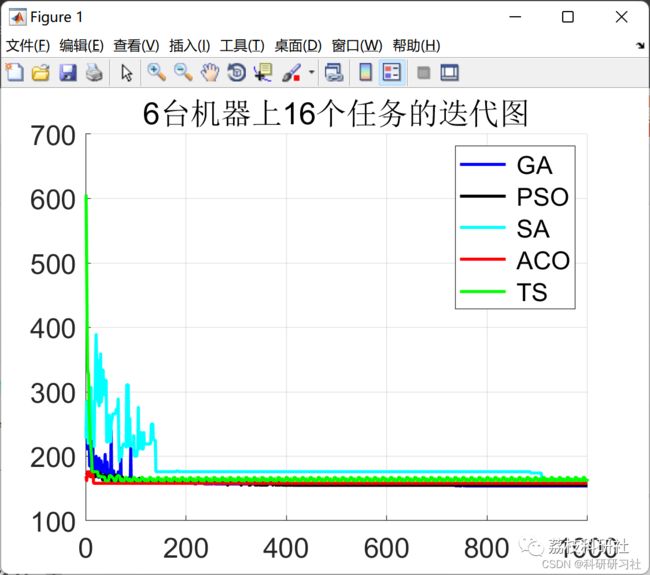

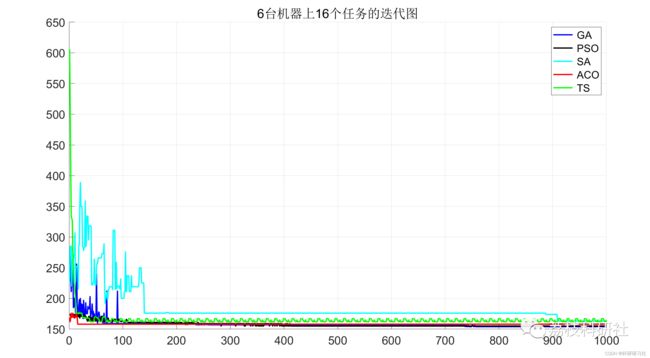

本文包括五种优化算法进行比较,分别是:遗传算法、粒子群优化算法、模拟退火算法、蚂蚁算法、禁忌搜索算法

2.2 main1运行结果

下面看看运行结果比较:

2.2 main2运行结果

3 Matlab代码

function [costs, bestSol] = PSO(jobs, m, n, particals, iterations, costFunc)c1 = 1.4944;c2 = 1.4944;w = 0.79;gbests = ones(1, n);gbest = costFunc(gbests, jobs, m, n);lbests = randi(m, particals, n);lbest = ones(1, particals);costs = ones(iterations, 1);costsEnd = 0;for i = 1:particalslbest(i) = costFunc(lbests(i, :), jobs, m, n);if lbest(i) < gbestgbest = lbest(i);gbests = lbests(i, :);endendx = lbests;v = zeros(particals, n);for i = 1:iterationsibest = costFunc(ones(particals, n), jobs, m, n);r1 = rand(particals, 1);r2 = rand(particals, 1);v = w*v + c1 * bsxfun(@times, r1, lbests - x) + ...c2 * bsxfun(@times, r2, (bsxfun(@minus, gbests, x)));x = round(x + v);%x = bsxfun(@mod, x, m) + 1;x(x < 1) = 1;x(x > m) = m;for j = 1:particalsc = costFunc(x(j, :), jobs, m, n);if c < ibestibest = c;endif c < lbest(j)lbest(j) = c;lbests(j, :) = x(j, :);endendcostsEnd = costsEnd + 1;costs(costsEnd) = ibest;[ilbest, idx] = min(lbest);%ibestilbests = lbests(idx, :);if ilbest < gbestgbest = ilbest;gbests = ilbests;endendbestSol = gbests;end

function [costs, bestSol] = PSO(jobs, m, n, particals, iterations, costFunc) c1 = 1.4944; c2 = 1.4944; w = 0.79; gbests = ones(1, n); gbest = costFunc(gbests, jobs, m, n); lbests = randi(m, particals, n); lbest = ones(1, particals); costs = ones(iterations, 1); costsEnd = 0; for i = 1:particals lbest(i) = costFunc(lbests(i, :), jobs, m, n); if lbest(i) < gbest gbest = lbest(i); gbests = lbests(i, :); end end x = lbests; v = zeros(particals, n);

完整代码:基于GA/PSO/SA/ACO/TS优化算法的车间调度比较

function [costs, bestSol] = PSO(jobs, m, n, particals, iterations, costFunc) c1 = 1.4944; c2 = 1.4944; w = 0.79; gbests = ones(1, n); gbest = costFunc(gbests, jobs, m, n); lbests = randi(m, particals, n); lbest = ones(1, particals); costs = ones(iterations, 1); costsEnd = 0; for i = 1:particals lbest(i) = costFunc(lbests(i, :), jobs, m, n); if lbest(i) < gbest gbest = lbest(i); gbests = lbests(i, :); end end x = lbests; v = zeros(particals, n);

function [costs, bestSol] = PSO(jobs, m, n, particals, iterations, costFunc) c1 = 1.4944; c2 = 1.4944; w = 0.79; gbests = ones(1, n); gbest = costFunc(gbests, jobs, m, n); lbests = randi(m, particals, n); lbest = ones(1, particals); costs = ones(iterations, 1); costsEnd = 0; for i = 1:particals lbest(i) = costFunc(lbests(i, :), jobs, m, n); if lbest(i) < gbest gbest = lbest(i); gbests = lbests(i, :); end end x = lbests; v = zeros(particals, n);

function [costs, bestSol] = PSO(jobs, m, n, particals, iterations, costFunc) c1 = 1.4944; c2 = 1.4944; w = 0.79; gbests = ones(1, n); gbest = costFunc(gbests, jobs, m, n); lbests = randi(m, particals, n); lbest = ones(1, particals); costs = ones(iterations, 1); costsEnd = 0; for i = 1:particals lbest(i) = costFunc(lbests(i, :), jobs, m, n); if lbest(i) < gbest gbest = lbest(i); gbests = lbests(i, :); end end x = lbests; v = zeros(particals, n);

4 参考文献

[1]王玉芳,曾亚志,蒋亚飞.基于自适应灰狼优化算法的柔性作业车间调度问题[J].现代制造工程,2022(7):1-10

[2]张守京,杜昊天,侯天天.求解多目标双资源柔性车间调度问题的改进NSGA-Ⅱ算法[J].机械科学与技术,2022,41(5):771-778

[3]黄学文,陈绍芬,周阗玉,孙宇婷.求解柔性作业车间调度的遗传算法综述[J].计算机集成制造系统,2022,28(2):536-551

部分理论引用网络文献,如有侵权请联系删除。