【翻译】智能制造中EDA 应用及益处系列之五: 机队匹配及管理

在本系列的第四篇文章“故障检测和分类”中,我们重点介绍了到目前为止业界采用EDA(设备数据采集)标准的主要驱动因素,即故障检测和分类(FDC)。在本文中,我们将讨论另一个有效利用EDA标准功能的重要应用程序:机队匹配和管理。

问题陈述

机队匹配(也包括工艺腔匹配和设备匹配)解决的问题是在现代晶圆厂中,在同一操作点维护大量相似的设备类型,以便通过运行实时调度和派送系统最大限度地提高调度产品批次的灵活性。这避免了特定设备实例被专用于(因此保留给)特定产品、流程或配方的关键层的情况,这种情况会降低受影响工艺区域的有效产能。这种状况的出现是因为随着时间的推移,特别是当对设备进行手动调整,或者其他影响因素(保养维护动作、易耗材料的更换、关键子系统的替换等),设备的性能会产生自然的“漂移”。

当然,部分问题在于选择哪台设备作为被匹配的对象,也就是所谓的“黄金设备”。此外,根据fab产品/工艺组合的广度,可能会有多个目标可供选择,从而使任务进一步复杂化。

解决方案组件

当下许多复杂生产制造问题的解决方案都需要大量高质量的设备数据,机队匹配也不例外。和FDC一样,选择黄金设备也需要一些信息,关于最近哪些批次的产量最高,这些信息必须与整个过程中使用的设备相关。然而与FDC不同的是,没有必要为特定于各种上下文组合去建立数百个(如果不是数以千计)多元故障模型的,因为工艺腔/设备/机队匹配的基本原则是“如果一组设备所有的基本运行机制一直在持续的工作,那么设备的行为总应该同样是一致的。这意味着匹配过程可以在很大程度上独立于配方,这比其他基于统计的应用程序简化了很多。

这并不像乍看起来那么简单,因为一个复杂的设备可能有许多这样的机制(压力/流量控制、多区域温度控制、运动控制、功率/相位生成等),必须收集数千个参数才能准确地描述和监视设备行为。静态和动态设备配置信息也会发挥作用,因为类似的(但不相同的)工具可以在某些过程中互换。

这就是EDA标准发挥作用的地方。

利用EDA标准

尽管SEMI EDA标准没有明确要求,但是它的设计者的意图和期望是支持一个比现实中大多数SECS/GEM实现更丰富(阅读“更多细节”)的设备元数据模型。关于机队匹配和管理,这不仅包括设备关键控制机制的高级状态变量(如上面列出的),还包括设定值、内部控制参数以及它们的底层组件的详细状态。

元数据模型还必须包含掌控设备操作的整套设备常量,因为这些“常量”有时会被操作人员在允许的范围内“动态地”更改。虽然这可能是一种可接受的生产实践,但它仍然影响设备的操作窗口,并且在匹配算法中必须考虑到这一点。

此外,通信接口应该支持这些详细参数的采样和数据收集,频率要足够观察这些控制机制完整实时运行,以便工艺和设备工程师能够更深入地了解设备的实际工作方式。支持这种层次的设备可见性也是EDA标准的一项规定要求。

一旦收集了这些数据,各种分析工具就可以在设备参数中寻找相似性和异常,从而确定实现工艺性能一致性最重要的因素。在撰写本文时,许多公司将该领域视为人工智能和机器学习技术的理想应用。请继续关注这一领域令人兴奋的发展。

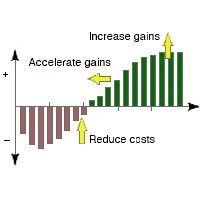

影响的KPI

受机队匹配和管理应用程序影响最大的KPI(关键性能指标)是整个工厂生产周期,因为调度系统可以优化利用所有可用的设备来在晶圆厂内运送材料。

设备的上线时间也得到了改善,因为作为机队匹配基础的设备持续的“辨识”过程也在某些潜在问题导致整个工具失败之前捕捉到了它们。最后,当更多的设备实例可用来运行实验批次时(而不是使用指定的设备),也可以缩短新工艺的产量提升所需要的时间。

如果你目前面临的挑战是如何让一大批本应相同的设备始终如一的运行,请联系我们。我们可以帮助您理解构建标准化的智能制造数据收集基础设施,以支持最新一代制造应用程序中日益流行的机器学习算法……包括机队匹配和管理。

EDA Applications and Benefits for Smart

Manufacturing Episode 5: Fleet Matching and Management

In the fourth article of this series, Fault Detection and Classification, we highlighted the application that has been the principal driver for the adoption of EDA (Equipment Data Acquisition) standards across the industry thus far, namely Fault Detection and Classification (FDC). In this posting, we’ll discuss another important application that effectively leverages the capabilities of the EDA standard: Fleet Matching and Management.

Problem Statement

The problem that fleet matching (which also covers chamber and tool matching) addresses is maintaining large sets of similar equipment types at the same operating point in order to maximize lot scheduling flexibility by the real-time scheduling and dispatching systems that run modern wafer fabs. This avoids the situation where specific equipment instances are dedicated to (and therefore reserved for) critical layers of certain products, processes or recipes, which can reduce the effective capacity of the affected process area. This situation can arise because tools naturally “drift” apart over time, especially when manual adjustments are made to the equipment, or other factors (maintenance actions, consumable material changes, key sub-system replacements, etc.) affect the equipment’s operating envelope.

Of course, part of the problem is choosing which equipment should be the one matched to—the so-called “golden tool.” And depending on the breadth of the fab’s product/process mix, there may be multiple targets to choose from, further complicating the task.

Solution Components

The solutions for many of today’s complex manufacturing problems require lots of high-quality equipment data, and fleet matching is no exception. Like FDC, choosing the golden tool(s) also requires some information about which recent lots exhibited the highest yields, which must be correlated with the equipment used throughout the process. Unlike FDC, however, it is NOT necessary to build hundreds (if not thousands) of multivariate fault models specific to the various context combinations, because the underlying principle of chamber/tool/fleet matching is that “if all the fundamental operating mechanisms of a set of equipment are working consistently, then the behavior of the equipment in aggregate should likewise be consistent.” This means that the matching process can be largely recipe independent, which is a major simplification over other statistically based applications.

This is not as simple as it may first appear, because a complex equipment may have scores of these mechanisms (pressure/flow control, multi-zone temperature control, motion control, power/phase generation, etc.) for which thousands of parameters must be collected to characterize and monitor equipment behavior accurately. Static and dynamic equipment configuration information also comes into play, since similar (but not identical) tools may be interchangeable for certain processes.

This is where the EDA standards enter the picture.

EDA Standards Leverage

Although not explicitly required by the SEMI EDA standards, the intent and expectation of its designers was to support a far richer (read “more detailed”) equipment metadata model than is practical in most SECS/GEM implementations. With respect to fleet matching and management, this would include not just the high-level status variables for key equipment mechanisms (listed above), but also the setpoints, internal control parameters, and detailed status of their underlying components.

The metadata model must also include the complete set of equipment constants that govern tool operation, since these “constants” are sometimes changed “on the fly” by an operator within some allowable range. While this may be an acceptable production practice, it nevertheless affects the tool’s operating window, and must be accounted for in the matching algorithms.

Moreover, the communications interface should support sampling and data collection of these detailed parameters at a frequency sufficient to observe the complete real-time operation of these mechanisms so the process and equipment engineers can more deeply understand how the equipment actually works. Support for this level of equipment visibility was also a stated requirement for the EDA standards.

Moreover, the communications interface should support sampling and data collection of these detailed parameters at a frequency sufficient to observe the complete real-time operation of these mechanisms so the process and equipment engineers can more deeply understand how the equipment actually works. Support for this level of equipment visibility was also a stated requirement for the EDA standards.

Once this data is collected, a variety of analysis tools can look for similarities and anomalies in the equipment parameters to identify the factors that matter most in achieving consistent

process performance. At this writing, a number of companies are looking at this domain as an ideal application for Artificial Intelligence and Machine Learning technology. Stay tuned for exciting developments in this area.

KPIs Affected

The KPI (Key Performance Indicators) most impacted by the fleet matching and management application is overall factory cycle time, since the scheduling systems can make optimal use of all available equipment to move material through the fab.

Equipment uptime is also improved, because the continuous equipment mechanism “fingerprinting” process which is fundamental to fleet matching also catches potential problems before they cause the entire tool to fail. Finally, when more equipment instances are available for running experimental lots (rather than having dedicated tools for this), the yield ramp for new processes can be shortened as well.

Equipment uptime is also improved, because the continuous equipment mechanism “fingerprinting” process which is fundamental to fleet matching also catches potential problems before they cause the entire tool to fail. Finally, when more equipment instances are available for running experimental lots (rather than having dedicated tools for this), the yield ramp for new processes can be shortened as well.

If keeping a large set of supposedly identical equipment operating consistently is a challenge you currently face, give us a call. We can help you understand the approaches for building a standards-based

Smart Manufacturing data collection infrastructure to support the machine learning algorithms that are increasingly prevalent in this latest generation of manufacturing applications… including fleet matching and management.

Posted by Alan Weber: Vice President, New Product Innovations on Sep 5, 2018 10:30:00 AM