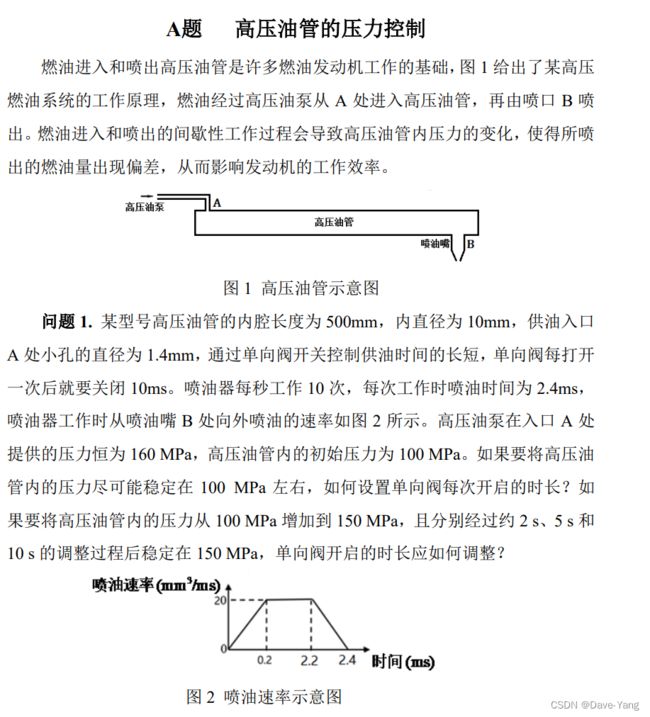

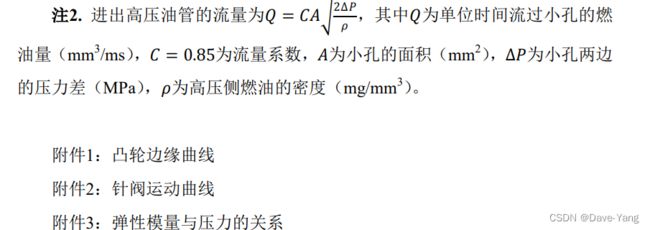

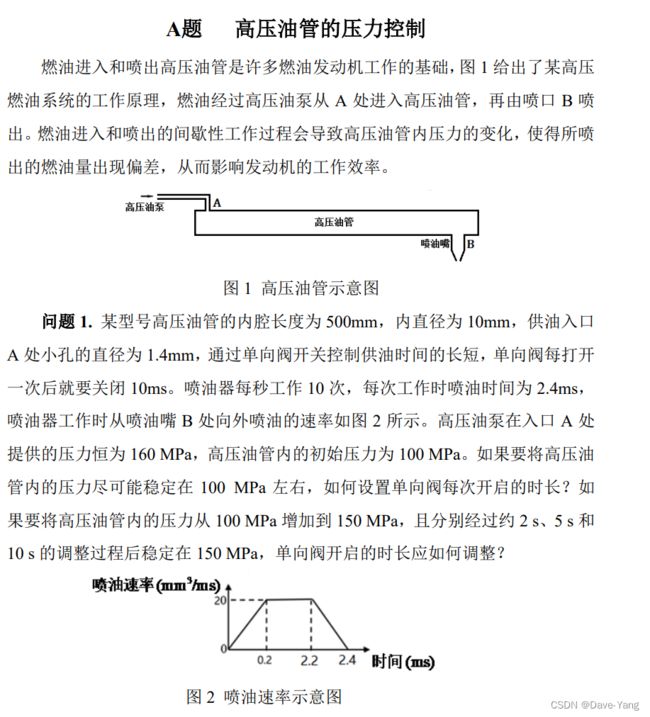

问题背景

各参数计算公式

弹性模量计算压力

function k = E2P(P,E)

k = polyfit(P,E,2);

end

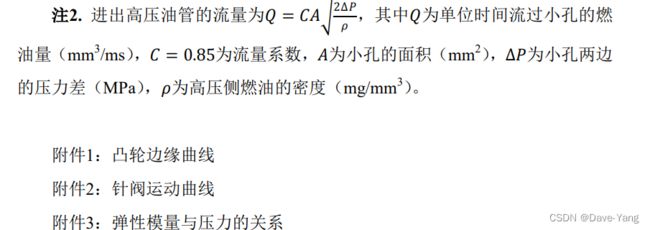

进油公式

function Q = Q_in(P1,P2,rho,t,T)

%% 仿真时间t时刻的进油量流量函数

C = 0.85;

A = pi*1.4*1.4/4;

t_convert = mod(t,T+10);

if t_convert <= T

Q = C*A*sqrt(2*(P1-P2)/rho);

else

Q = 0;

end

end

出油公式

function Q = Q_out(t)

%% 仿真时间t时刻的出油量流量函数

% 假设喷油嘴每秒以均匀频率工作10次,此时喷油量可看作周期函数

t_convert = mod(t,100); % 周期转换

if t_convert <= 0.2 && t_convert >= 0

Q = 100*t_convert;

elseif 0.2

欧拉法计算密度

function rho = rho_iter(rho0,dP,E,P)

if P > 100

rho = rho0*(1+dP/E);

else

rho = rho0*(1-dP/E);

end

end

密度计算压力

clear;clc

data = readmatrix('附件3-弹性模量与压力.xlsx','Range','A2:B402');

P = data(:,1);

E = data(:,2);

rho = zeros(size(P));

ind = find(P==100);

rho(ind) = 0.85;

n = length(P);

dP = mean(diff(P,1));

for i = ind:n-1

rho(i+1) = rho_iter(rho(i),dP,E(i),P(i));

end

for i = ind:-1:2

rho(i-1) = rho_iter(rho(i),dP,E(i),P(i));

end

k = polyfit(rho,P,2);

P_test = k(1)*rho.^2+k(2)*rho+k(3);

plot(rho,P)

hold on

plot(rho,P_test)

function P = rho2P(rho)

k = [10952.7722859703,-15955.0071828209,5749.08734491654];

P = k(1)*rho.^2+k(2)*rho+k(3);

end

压力计算

function [P,rho,M] = P_vessel(P1,P2,t,T,rho1,rho2,M,V,Qout,dt)

Qin = Q_in(P1,P2,rho1,t,T);

M = M+dt*rho1*Qin-dt*rho2*Qout;

rho = M/V;

P = rho2P(rho);

end

各时刻压力仿真计算

function [t,P] = pipe_sim(P0,T,t_sim)

%% 基本参数设置

% 油管参数

L = 500; % 油管长度

d_pipe = 10; % 油管直径

V = L*pi*(d_pipe/2)^2; % 油管体积

% 仿真时间参数

dt = 0.1;

t = 0:dt:t_sim; t = t';

% 状态量参数

rho0 = 0.8707;

Qout = zeros(size(t)); % 出油量

P = zeros(size(t)); P(1) = 100; % 管内压力

rho = zeros(size(t)); rho(1) = 0.85; % 管内燃油密度

M = zeros(size(t)); M(1) = rho(1)*V; % 管内燃油质量

for i = 1:length(t)

Qout(i) = Q_out(i);

end

for i = 1:length(t)-1

[P(i+1),rho(i+1),M(i+1)] = P_vessel(P0,P(i),t(i),T,rho0,rho(i),M(i),V,Qout(i),dt);

end

end

粒子群法计算单次阀门开启时间

function [e,T] = scope_T(P_target,t_sim,P0)

%% 粒子群算法中的预设参数

n = 10; % 粒子数量

narvs = 1; % 变量个数

c1 = 2; % 每个粒子的个体学习因子,也称为个体加速常数

c2 = 2; % 每个粒子的社会学习因子,也称为社会加速常数

w = 0.9; % 惯性权重

K = 50; % 迭代的次数

vmax = 1.2; % 粒子的最大速度

x_lb = 0; % x的下界

x_ub = 1; % x的上界

%% 初始化粒子的位置和速度

x = zeros(n,narvs);

for m = 1: narvs

x(:,m) = x_lb(m) + (x_ub(m)-x_lb(m))*rand(n,1);

end

v = -vmax + 2*vmax .* rand(n,narvs);

%% 计算适应度

fit = zeros(n,1);

for m = 1:n

fit(m) = Obj_fun(P0,x(m,:),t_sim,P_target);

end

pbest = x;

ind = find(fit == max(fit), 1);

gbest = x(ind,:);

%% 迭代K次来更新速度与位置

fitnessbest = ones(K,1);

for d = 1:K

for m = 1:n

v(m,:) = w*v(m,:) + c1*rand(1)*(pbest(m,:) - x(m,:)) + c2*rand(1)*(gbest - x(m,:)); % 更新第i个粒子的速度

% 如果粒子的速度超过了最大速度限制,就对其进行调整

for j = 1: narvs

if v(m,j) < -vmax(j)

v(m,j) = -vmax(j);

elseif v(m,j) > vmax(j)

v(m,j) = vmax(j);

end

end

x(m,:) = x(m,:) + v(m,:); % 更新第i个粒子的位置

% 如果粒子的位置超出了定义域,就对其进行调整

for j = 1: narvs

if x(m,j) < x_lb(j)

x(m,j) = x_lb(j);

elseif x(m,j) > x_ub(j)

x(m,j) = x_ub(j);

end

end

fit(m) = Obj_fun(P0,x(m,:),t_sim,P_target);

if fit(m) > Obj_fun(P0,pbest(m,:),t_sim,P_target)

pbest(m,:) = x(m,:);

end

if fit(m) > Obj_fun(P0,gbest,t_sim,P_target)

gbest = pbest(m,:);

end

end

fitnessbest(d) = Obj_fun(P0,gbest,t_sim,P_target);

end

T = gbest;

e = fitnessbest;

end

function e = Obj_fun(P0,x,t_sim,P_target)

[~,P] = pipe_sim(P0,x,t_sim);

P_mean = mean(P(80000:100000));

e = -abs(P_mean-P_target);

end

仿真过程

clear;clc

%% 仿真过程

t_sim = 10000;

P0 = 160;

P_target = input('请输入稳定时的压强:');

[e,T] = scope_T(P_target,t_sim,P0); e = -e;

[t,P] = pipe_sim(P0,T,t_sim);

%% 作图

figure(1)

plot(t,P,'k')

xlabel('时间/ms')

ylabel('压力/MPa')

axis([0 t_sim 0 200])

figure(2)

plot(e,'k')

xlabel('迭代次数')

ylabel('误差')