【STM32】实战3.1—用STM32与TB6600驱动器驱动42步进电机(一)

目录

0 参考资料出处

1 实验预期效果

2 硬件学习

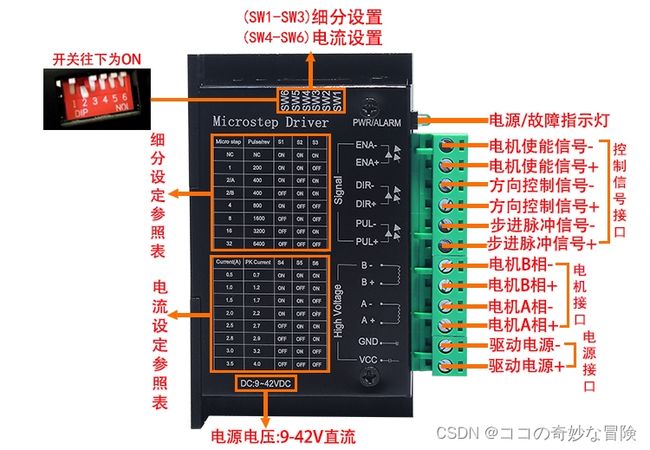

2.1 TB6600驱动器

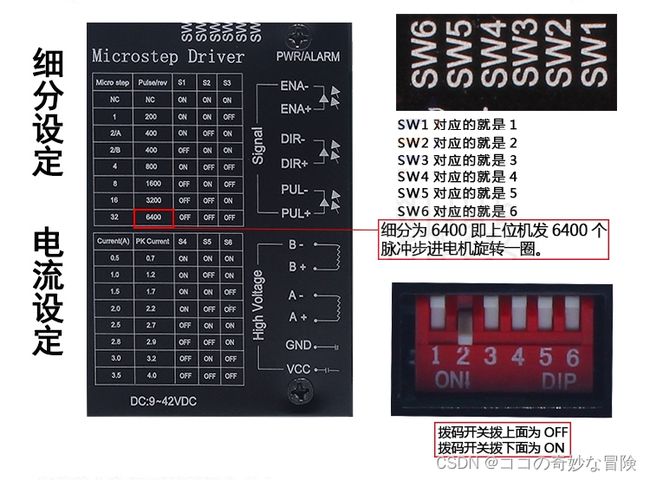

2.1.1 通过拨码开关设定细分与电流

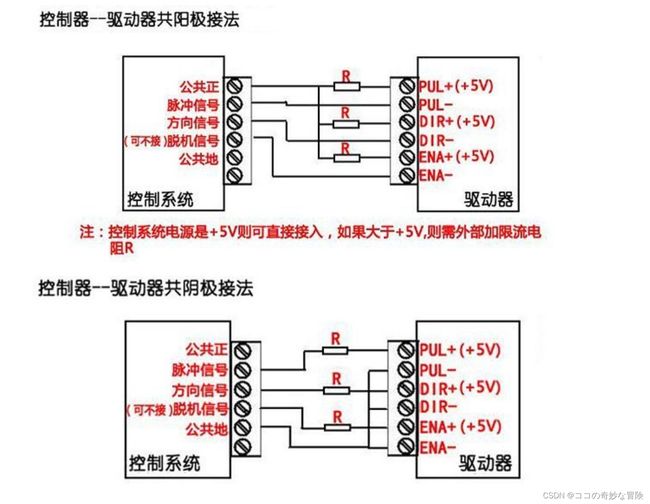

2.1.2 共阴共阳接线法

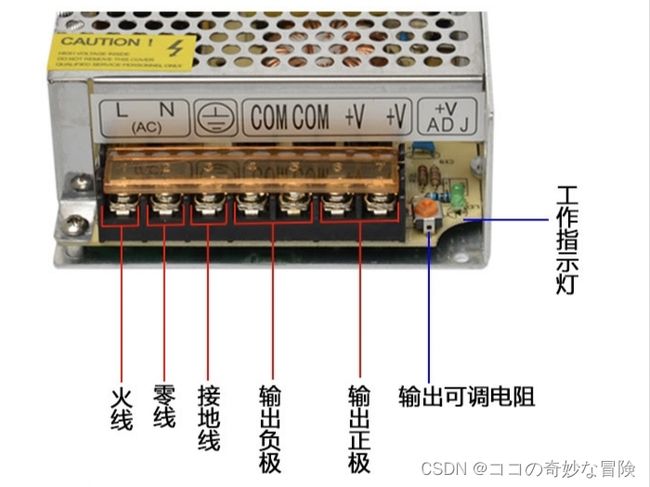

2.2 开关电源(AC转DC变压器)& 电源线

2.3 42步进电机

2.3.1 基本知识

2.3.2 转速细分控制

2.3.3 满步、半步、微步驱动原理

3 软件配置与硬件接线

3.1 STM32CubeMX的配置

3.1.1 配置定时器TIM2 编辑

3.1.2 配置引脚PA1

3.2 驱动器的接线方式

3.3 细分与电流调节

编辑

4 代码编写

5 最终效果

6 附录

6.1 TB6600驱动器

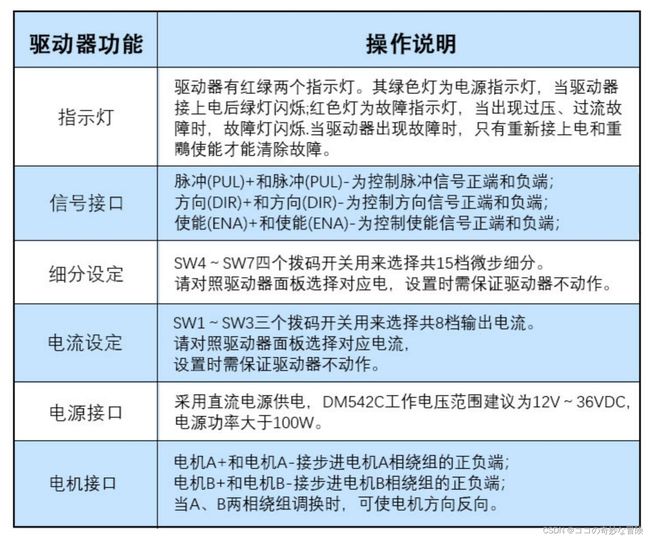

6.1.1 驱动器功能

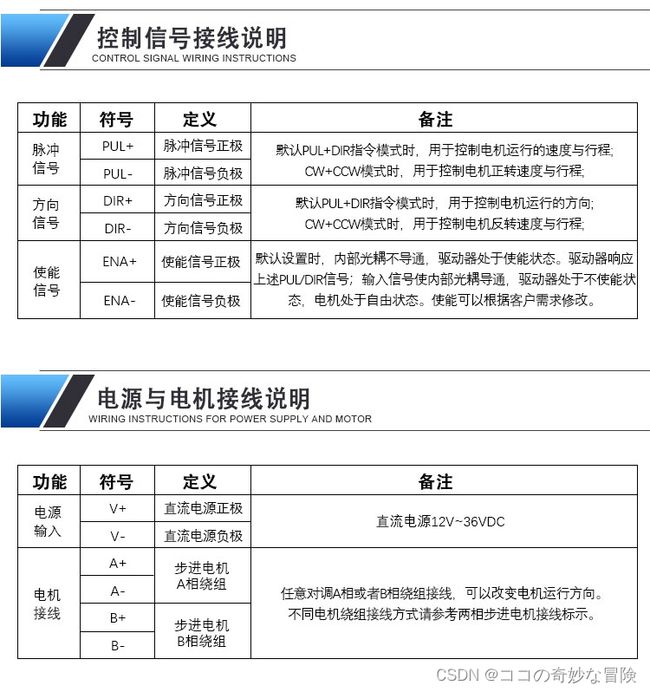

6.1.2 接线

6.1.3 常见故障及对策

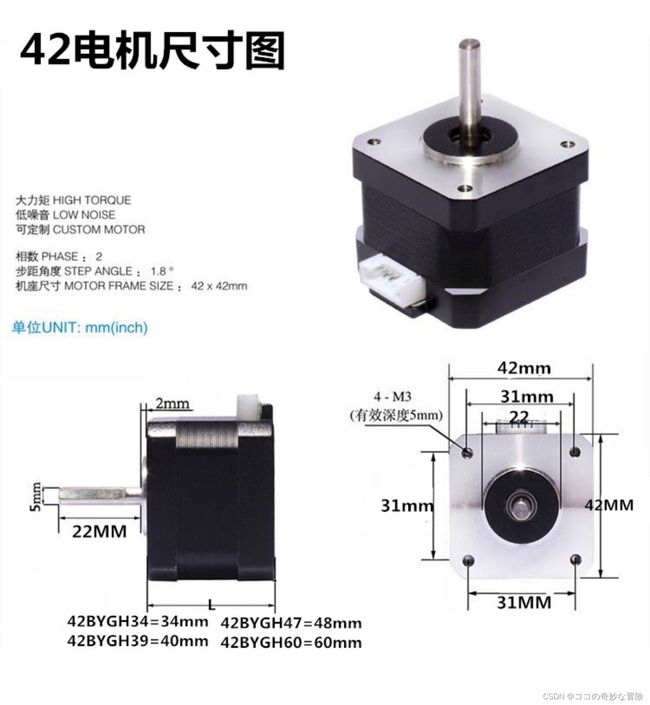

6.2 42步进电机尺寸图与内部结构

0 参考资料出处

参考博客:

1、利用STM32F103精确控制步进电机_jl_mlh的博客-CSDN博客_stm32控制步进电机;

2、图文介绍步进电机的满步、半步、微步驱动原理-深圳东么川伺服控制有限公司;

3、【STM32】stm32驱动TB6600控制42/57步进电机的案例(TIM中断和PWM实验)_创客协会的阿蛋°的博客-CSDN博客_stm32驱动42步进电机程序;

4、STM32之TIM定时器驱动42步进电机-驱动器型号TB6600_为丽力的博客-CSDN博客_stm32驱动42步进电机;

参考论文:

1、侯艳霞. 混合式步进电机工作原理及其PLC控制;

1 实验预期效果

完成步进电机的正转(不通过串口控制、非可移动供电)。

2 硬件学习

2.1 TB6600驱动器

2.1.1 通过拨码开关设定细分与电流

2.1.2 共阴共阳接线法

共阴:

驱动器 —— stm32

DIR- 与 PUL- —— GND

DIR+ —— 方向引脚

PUL+ —— 脉冲引脚共阳:

驱动器 —— stm32

DIR+ 与 PUL+ —— +5V

DIR- —— 方向引脚

PUL- —— 脉冲引脚

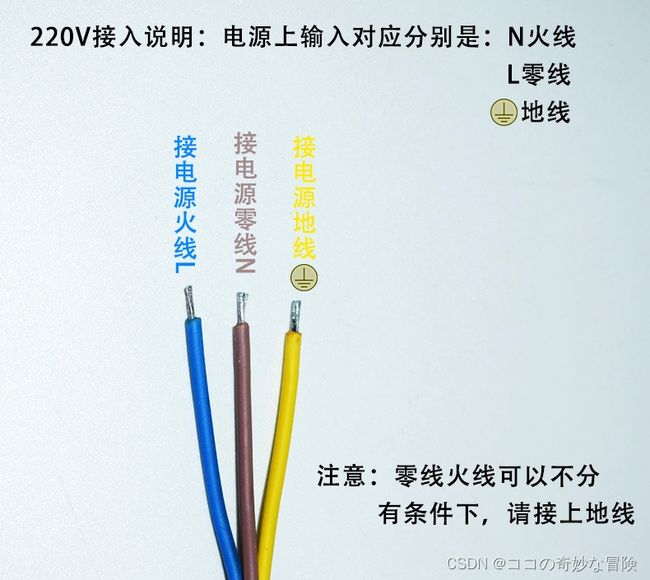

2.2 开关电源(AC转DC变压器)& 电源线

2.3 42步进电机

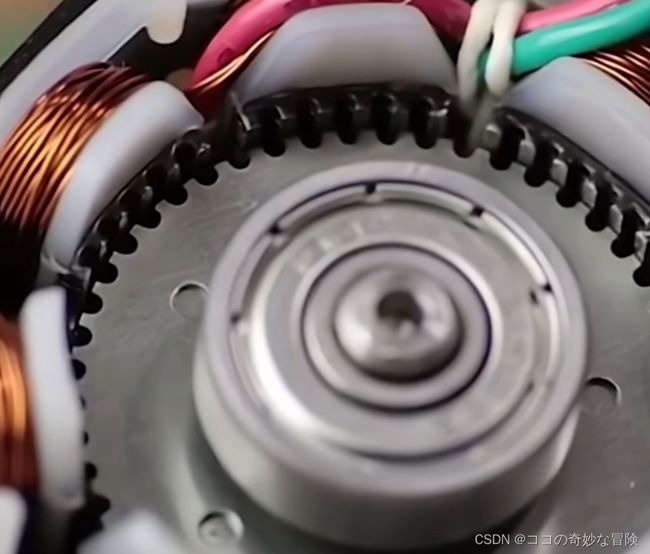

2.3.1 基本知识

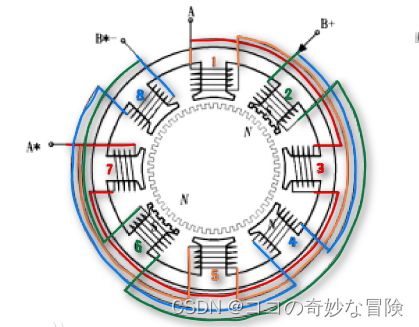

由商家提供资料可知:42步进电机的相数为2(A、B两相,每相并联支路数为2,每条支路串联2个线圈)、步距角为1.8°(满步时)、转子齿数为50。

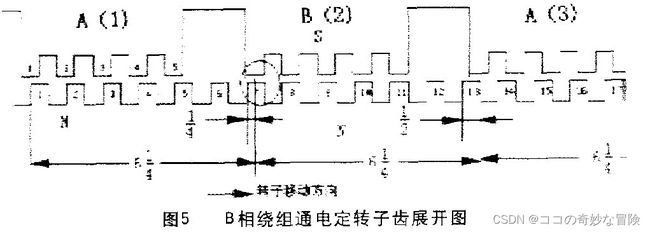

每拍只有一相绕组通电,四拍构成一个循环。上图中,定子的B相通电,磁极2的5个齿与转子齿对齿(如下图4),由分析可知,磁极6也同转子齿对齿,而磁极4和8是齿对槽(如下图2)。旁边的A相绕组的磁极3的5个齿和转子齿有1/4齿距的错位(如下图3),即1.8°(360°/50/4)。

当B相断电A相通电时,磁极3产生N极性,吸合离它最近的S极转子齿,使得转子沿顺时针方向转过1.8°,实现磁极3和转子齿对齿,此时磁极4和转子齿有1/4齿距的错位。

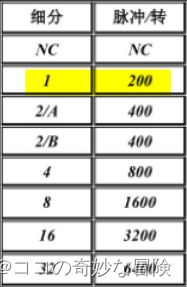

依次类推若继续按四拍的顺序通电,转子就按顺时针方向一步一步地转动,每通电一次(即每来一个脉冲)转子转过1.8°,即称步距角为1.8°,转子转过一圈需要360°/1.8° =200个脉冲。与表相符。

【参数及公式可参阅文章:利用STM32F103精确控制步进电机_jl_mlh的博客-CSDN博客】

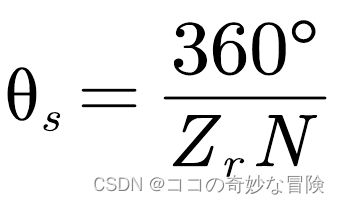

① 拍数(N=km)——每一次循环所包含的通电状态数(电机转过一个齿距角所需脉冲数);

单拍制(k=1)——拍数 = 相数;双拍制(k=2)——拍数 = 相数的两倍;② 相数(m)——即电机内部的线圈组数。如果使用细分驱动器,则相数将变得没有意义,只需在驱动器上改变细分数,就可以改变步距角;

③ 转子齿数(Zr);

④ 步距角(θs)——步进机通过一个电脉冲转子转过的角度;

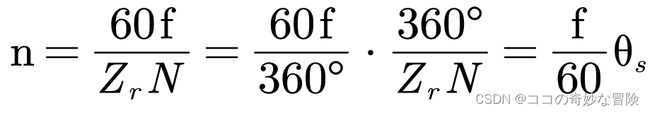

⑤ 转速(n)

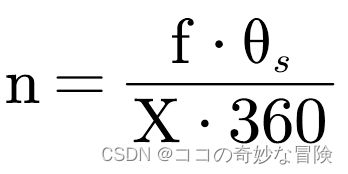

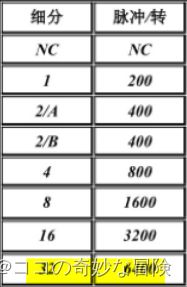

2.3.2 转速细分控制

电机的转速与脉冲频率成正比,电机转过的角度与脉冲数成正比。所以控制脉冲数和脉冲频率就可以精确调速。

f:脉冲频率;θs:步距角;X:细分值;n:转速(rad/s)。

若已知步距角=1.8°,细分值=32,想要达到1rad/s的转速(每秒转一圈),则脉冲频率=1*32*360/1.8=6400,即6400个脉冲为一转,与所给表相符合。

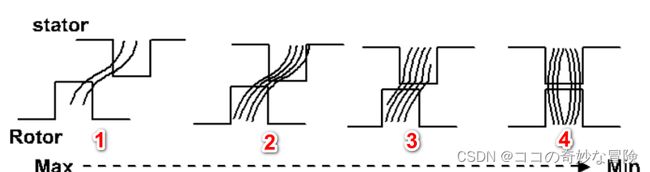

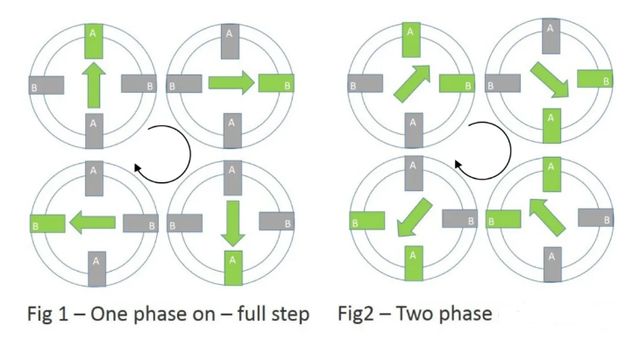

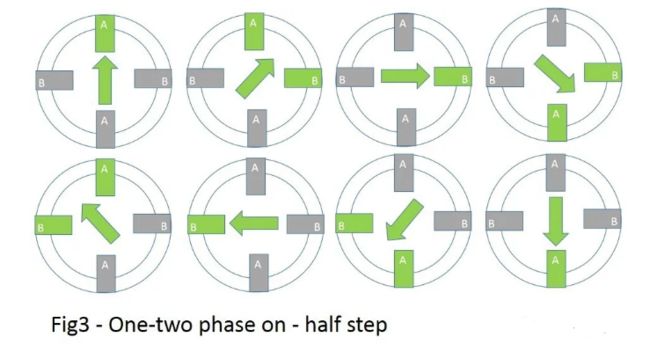

2.3.3 满步、半步、微步驱动原理

【该部分摘自文章:图文介绍步进电机的满步、半步、微步驱动原理】

满步驱动(单拍满步驱动和双拍满步驱动 ):

半步驱动:

半步驱动的好处是提高分辨率,但是缺点是扭矩只有满步驱动的70%,当然,也可以通过优化线圈中电流大小,来提高半步驱动扭矩。

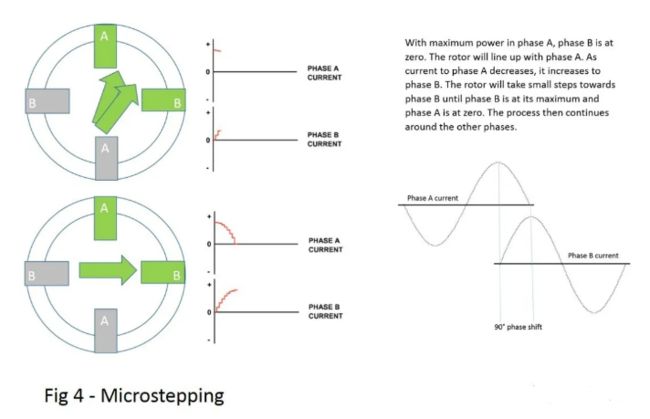

微步驱动:

图上英文为:With maximum power in phase A, phase B is at zero. The rotor will line up with phase A. As current to phase A decreases, it increases to phase B. The rotor will take small steps towards phase B until phase B is at its maximum and phase A is at zero. The process then continues around the other phases.

翻译过来大致意思就是:A线圈开始有最大电流,B线圈电流为0,转子指向A线圈。如果A线圈电流慢慢减小,B线圈电流慢慢增大,转子就会慢慢的转向B线圈。

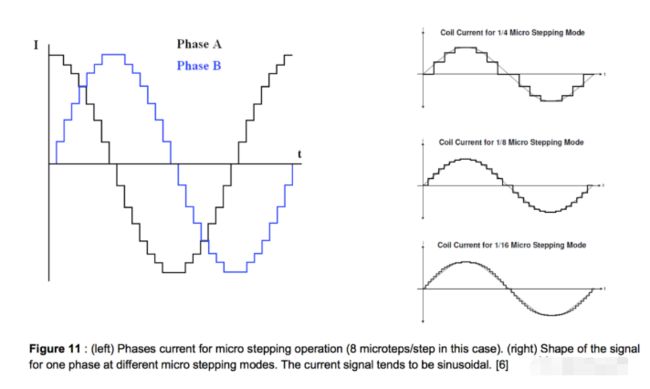

宏观来看,A、B线圈的电流变化都接近于三角函数曲线。电流每一步变化的大小,则决定了微步运动的大小。虽然步数越多,运动越平滑,但是扭矩也会相应的减小。

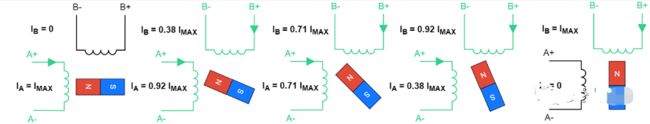

电流每一步的变化的大小,决定了微步运动的大小,右上图为1/4,1/8,1/16微步电流变化示意图。

微步运动举例:在图1中,A线圈通满电流,图2中A线圈通最大电流的0.92倍,而B线圈通最大电流的0.38倍,实现22.5°旋转。同理,图3中,A和B线圈同时通最大电流的0.71倍,可以实现45°旋转。

步数越多,可以获得越平滑的运动,噪声也越小,不容易失步(丢步),但是代价就是扭矩大大减小。

3 软件配置与硬件接线

3.1 STM32CubeMX的配置

【基础配置见【STM32】1—零基础硬件软件配置 & 完成LED的闪烁_ココの奇妙な冒険的博客-CSDN博客_stm32配置软件】

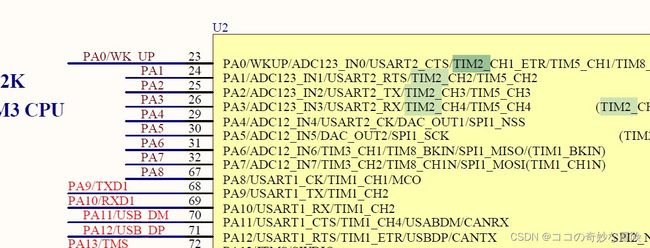

原理图:

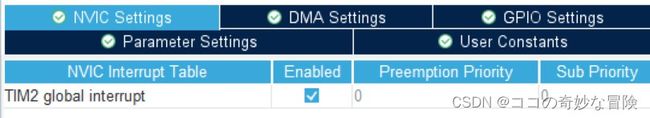

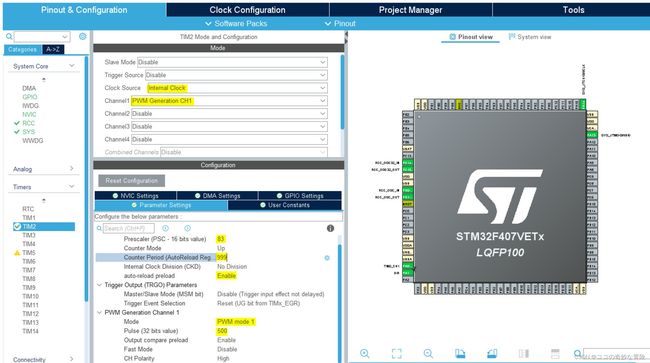

3.1.1 配置定时器TIM2

其输出引脚为PA0。

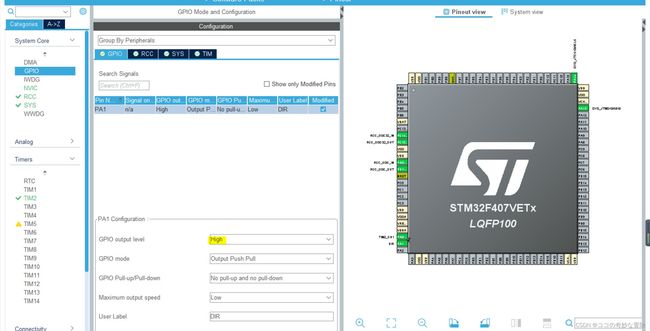

3.1.2 配置引脚PA1

因希望其正转,则将电平拉高:

3.2 驱动器的接线方式

采用共阴接法:

3.3 细分与电流调节

相关见2.1.1

4 代码编写

【代码参考博客STM32之TIM定时器驱动42步进电机-驱动器型号TB6600_stm32驱动42步进电机】

在自动生成代码的基础上需在main.c中增加:

定义变量:

int count;开启PWM中断并拉高引脚(后者可省去):

HAL_TIM_PWM_Start_IT(&htim2,TIM_CHANNEL_1);

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET); 计数1000次后停转:

void HAL_TIM_PWM_PulseFinishedCallback(TIM_HandleTypeDef *htim)

{

if(htim == &htim2)

{

if(count <1000)

{

count++;

}

else

{

HAL_TIM_PWM_Stop_IT(&htim2, TIM_CHANNEL_1);

count = 0;

}

}

}

总代码如下:

main.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

#include "tim.h"

#include "gpio.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

int count;

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

/* USER CODE BEGIN PFP */

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_TIM2_Init();

/* USER CODE BEGIN 2 */

HAL_TIM_PWM_Start_IT(&htim2,TIM_CHANNEL_1);

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET);

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Configure the main internal regulator output voltage

*/

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE1);

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSI;

RCC_OscInitStruct.PLL.PLLM = 8;

RCC_OscInitStruct.PLL.PLLN = 168;

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV2;

RCC_OscInitStruct.PLL.PLLQ = 4;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV4;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV2;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_5) != HAL_OK)

{

Error_Handler();

}

}

/* USER CODE BEGIN 4 */

void HAL_TIM_PWM_PulseFinishedCallback(TIM_HandleTypeDef *htim)

{

if(htim == &htim2)

{

if(count <1000)

{

count++;

}

else

{

HAL_TIM_PWM_Stop_IT(&htim2, TIM_CHANNEL_1);

count = 0;

}

}

}

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

gpio.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file gpio.c

* @brief This file provides code for the configuration

* of all used GPIO pins.

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "gpio.h"

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/*----------------------------------------------------------------------------*/

/* Configure GPIO */

/*----------------------------------------------------------------------------*/

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/** Configure pins as

* Analog

* Input

* Output

* EVENT_OUT

* EXTI

*/

void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOC_CLK_ENABLE();

__HAL_RCC_GPIOH_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET);

/*Configure GPIO pin : PtPin */

GPIO_InitStruct.Pin = DIR_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

HAL_GPIO_Init(DIR_GPIO_Port, &GPIO_InitStruct);

}

/* USER CODE BEGIN 2 */

/* USER CODE END 2 */

tim.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file tim.c

* @brief This file provides code for the configuration

* of the TIM instances.

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "tim.h"

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

TIM_HandleTypeDef htim2;

/* TIM2 init function */

void MX_TIM2_Init(void)

{

/* USER CODE BEGIN TIM2_Init 0 */

/* USER CODE END TIM2_Init 0 */

TIM_ClockConfigTypeDef sClockSourceConfig = {0};

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_OC_InitTypeDef sConfigOC = {0};

/* USER CODE BEGIN TIM2_Init 1 */

/* USER CODE END TIM2_Init 1 */

htim2.Instance = TIM2;

htim2.Init.Prescaler = 83;

htim2.Init.CounterMode = TIM_COUNTERMODE_UP;

htim2.Init.Period = 999;

htim2.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim2.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_ENABLE;

if (HAL_TIM_Base_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sClockSourceConfig.ClockSource = TIM_CLOCKSOURCE_INTERNAL;

if (HAL_TIM_ConfigClockSource(&htim2, &sClockSourceConfig) != HAL_OK)

{

Error_Handler();

}

if (HAL_TIM_PWM_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

if (HAL_TIMEx_MasterConfigSynchronization(&htim2, &sMasterConfig) != HAL_OK)

{

Error_Handler();

}

sConfigOC.OCMode = TIM_OCMODE_PWM1;

sConfigOC.Pulse = 500;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

if (HAL_TIM_PWM_ConfigChannel(&htim2, &sConfigOC, TIM_CHANNEL_1) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN TIM2_Init 2 */

/* USER CODE END TIM2_Init 2 */

HAL_TIM_MspPostInit(&htim2);

}

void HAL_TIM_Base_MspInit(TIM_HandleTypeDef* tim_baseHandle)

{

if(tim_baseHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspInit 0 */

/* USER CODE END TIM2_MspInit 0 */

/* TIM2 clock enable */

__HAL_RCC_TIM2_CLK_ENABLE();

/* TIM2 interrupt Init */

HAL_NVIC_SetPriority(TIM2_IRQn, 0, 0);

HAL_NVIC_EnableIRQ(TIM2_IRQn);

/* USER CODE BEGIN TIM2_MspInit 1 */

/* USER CODE END TIM2_MspInit 1 */

}

}

void HAL_TIM_MspPostInit(TIM_HandleTypeDef* timHandle)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

if(timHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspPostInit 0 */

/* USER CODE END TIM2_MspPostInit 0 */

__HAL_RCC_GPIOA_CLK_ENABLE();

/**TIM2 GPIO Configuration

PA0-WKUP ------> TIM2_CH1

*/

GPIO_InitStruct.Pin = GPIO_PIN_0;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

GPIO_InitStruct.Alternate = GPIO_AF1_TIM2;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

/* USER CODE BEGIN TIM2_MspPostInit 1 */

/* USER CODE END TIM2_MspPostInit 1 */

}

}

void HAL_TIM_Base_MspDeInit(TIM_HandleTypeDef* tim_baseHandle)

{

if(tim_baseHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspDeInit 0 */

/* USER CODE END TIM2_MspDeInit 0 */

/* Peripheral clock disable */

__HAL_RCC_TIM2_CLK_DISABLE();

/* TIM2 interrupt Deinit */

HAL_NVIC_DisableIRQ(TIM2_IRQn);

/* USER CODE BEGIN TIM2_MspDeInit 1 */

/* USER CODE END TIM2_MspDeInit 1 */

}

}

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

5 最终效果

42步进电机的转动

6 附录

6.1 TB6600驱动器

某宝店家提供资料如下: