Automotive SPICE(2)

AS Automotive SPICE

BP Base Practice

CAN Controller Area Network

CASE Computer-Aided Software Engineering,

CCB Change Control Board

CFP Call For Proposals

CPU Central Processing Unit

ECU Electronic Control Unit

EEPROM Electrically Erasable Programmable Read-Only Memory

GP Generic Practice

GR Generic Resource

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

I/O Input / Output

ISO International Organization for Standardization

ITT Invitation To Tender

LIN Local Interconnect Network

MISRA Motor Industry Software Reliability Association

MOST Media Oriented Systems Transport

PA Process Attribute

PAM Process Assessment Model

PRM Process Reference Model

PWM Pulse Width Modulation

RAM Random Access Memory

ROM Read Only Memory

SPICE Software Process Improvement and Capability dEtermination

SUG Spice User Group

USB Universal Serial Bus

WP Work Product

WPC Work Product Characteristic

- Process capability determination

The concept of process capability determination by using a process assessment model is based on a two-dimensional framework. The first dimension is provided by processes defined in a process reference model (process dimension). The second dimension consists of capability levels that are further subdivided into process attributes (capability dimension). The process attributes provide the measurable characteristics of process capability.

用一个二维的概念来描述过程能力模型。 第一个维度是流程参考模型(流程维度)中定义的流程。 第二个维度由能力级别组成,这些级别进一步细分为流程属性(能力维度)。 过程属性使得过程能力具有可测性。

The process assessment model selects processes from a process reference model and supplements with indicators. These indicators support the collection of objective evidence which enable an assessor to assign ratings for processes according to the capability dimension. The relationship is shown in Figure 1:

过程评估模型从过程参考模型中选择一个过程并补充指标。 该指标用于收集客观证据,并允许评估员根据能力判断分配过程评级。 关系如图1所示。

3.1. Process reference model

Processes are grouped by process category and at a second level into process groups according to the type of activity they address. There are 3 process categories: Primary life cycle processes, Organizational life cycle processes and Supporting life cycle processes. Each process is described in terms of a purpose statement. The purpose statement contains the unique functional objectives of the process when performed in a particular environment. For each purpose statement a list of specific outcomes is associated, as a list of expected positive results of the process performance. For the process dimension, the Automotive SPICE process reference model provides the set of processes shown in Figure 2.

有3个流程类别:主要生命周期流程,组织生命周期流程和支持生命周期流程。 每个过程都是根据描述过程目标来描述的。 过程目标描述包括在特定环境中实施过程时的过程特定功能目标。 流程目标与流程结果列表相关联。 该过程结果是实施该过程时预期的理想结果列表。 Automotive SPICE过程参考模型为过程坐标提供了图2所示的一系列过程。

3.1.1. Primary life cycle processes category

The primary life cycle processes category consists of processes that may be used by the customer when acquiring products from a supplier, and by the supplier when responding and delivering products to the customer including the engineering processes needed for specification, design, development, integration and testing. The primary life cycle processes category consists of the following groups:

主要生命周期过程类别包括客户用于从供应商处获取产品的过程,以及供应商用于响应客户和交付产品的过程,以及规范,设计, 包括开发,集成和测试所需的工程流程。 主生命周期过程类别包括以下过程组。

• the Acquisition process group;

• the Supply process group;

• the System engineering process group;

• the Software engineering process group.

The Acquisition process group (ACQ) consists of processes that are performed by the customer, or by the supplier when acting as a customer for its own suppliers, in order to acquire a product and/or service.

采购流程组

供应流程组

系统工程流程组

软件工程流程组采购流程组

(ACQ)是客户为获取产品和/或服务或其他供应商的供应商而执行的流程 它由供应商在成为客户时实施的流程组成。

ACQ.3 Contract Agreement 合同协议

ACQ.4 Supplier Monitoring

ACQ.11 Technical Requirements

ACQ.12 Legal and Administrative Requirements 法律和行政要求

ACQ.13 Project Requirements

ACQ.14 Request for Proposals 提案请求

ACQ.15 Supplier Qualification 供应商资格

Table 2 — Primary life cycle processes – ACQ process group

The Supply process group (SPL) consists of processes performed by the supplier in order to supply a product and/or a service.

SPL.1 Supplier Tendering 供应商招标

SPL.2 Product Release 产品发布

Table 3 — Primary life cycle processes – SPL process group

The System Engineering process group (SYS) consists of processes addressing the elicitation and management of customer and internal requirements, the definition of the system architecture and the integration and testing on the system level.

SYS.1 Requirements Elicitation 需求提取

SYS.2 System Requirements Analysis

SYS.3 System Architectural Design

SYS.4 System Integration and Integration Test

SYS.5 System Qualification Test

The Software Engineering process group (SWE) consists of processes addressing the management of software requirements derived from the system requirements, the development of the corresponding software architecture and design as well as the implementation, integration and testing of the software.

SWE.1 Software Requirements Analysis

SWE.2 Software Architectural Design

SWE.3 Software Detailed Design and Unit Construction

SWE.4 Software Unit Verification

SWE.5 Software Integration and Integration Test

SWE.6 Software Qualification Test

3.1.2. Supporting life cycle processes category

The supporting life cycle processes category consists of processes that may be employed by any of the other processes at various points in the life cycle.

SUP.1 Quality Assurance

SUP.2 Verification

SUP.4 Joint Review

SUP.7 Documentation

SUP.8 Configuration Management

SUP.9 Problem Resolution Management

SUP.10 Change Request Management

3.1.3. Organizational life cycle processes category

The organizational life cycle processes category consists of processes that develop process, product, and resource assets which, when used by projects in the organization, will help the organization achieve its business goals. The organizational life cycle processes category consists of the following groups:

• the Management process group; 管理流程群

• the Process Improvement process group; 流程改进流程群

• the Reuse process group. 再利用流程群

The Management process group (MAN) consists of processes that may be used by anyone who manages any type of project or process within the life cycle.

MAN.3 Project Management

MAN.5 Risk Management

MAN.6 Measurement

The Process Improvement process group (PIM) covers one process that contains practices to improve the processes performed in the organizational unit.

PIM.3 Process Improvement

The Reuse process group (REU) covers one process to systematically exploit reuse opportunities in organization’s reuse programs.

再利用过程组(REU)由一个过程组成,是一个系统地利用组织重用程序中的重用机会的过程。

REU.2 Reuse Program Management

3.2 Measurement framework 衡量/测量框架

The measurement framework provides the necessary requirements and rules for the capability dimension. It defines a schema which enables an assessor to determine the capability level of a given process. These capability levels are defined as part of the measurement framework. 能力水平被定义为测量框架的一部分

To enable the rating, the measurement framework provides process attributes defining a measurable property of process capability. Each process attribute is assigned to a specific capability level. The extent of achievement of a certain process attribute is represented by means of a rating based on a defined rating scale. The rules from which an assessor can derive a final capability level for a given process are represented by a process capability level model.

Automotive SPICE 3.1 uses the measurement framework defined in ISO/IEC 33020:2015.

NOTE: Text incorporated from ISO/IEC 33020 within this chapter is written in italic font and marked with a left side bar.

3.2.1. Process capability levels and process attributes

The process capability levels and process attributes are identical to those defined in ISO/IEC 33020 clause 5.2. The detailed descriptions of the capability levels and the corresponding process attributes can be found in chapter 5.

过程能力等级和过程属性与ISO / IEC 33020子条款5.2中定义的相同。 第5章介绍了功能级别和相应的进程属性的详细信息。

Process attributes are features of a process that can be evaluated on a scale of achievement, providing a measure of the capability of the process. They are applicable to all processes.

流程属性是流程的一个特征,通过提供流程能力的测量项目,可以评估成就度。 流程属性适用于所有流程。

A capability level is a set of process attribute(s) that work together to provide a major enhancement in the capability to perform a process. Each attribute addresses a specific aspect of the capability level. The levels constitute a rational way of progressing through improvement of the capability of any process.

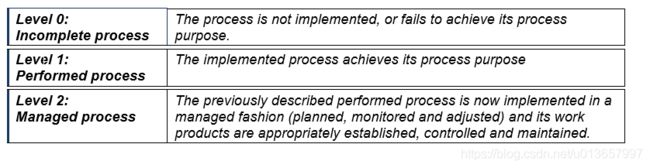

According to ISO/IEC 33020 there are six capability levels, incorporating nine process attributes:

基于ISO / IEC 33020,有六个能力等级,包括九个过程属性

L0:不完全流程

L1:已执行流程

L2(已管理流程):

上述“实施过程”在此以受控方式实施(计划,监测和协调方法),其工作产品得到适当建立,控制和维护。

L3(已确立流程):

上面提到的“管理过程”在这里使用可以实现其过程结果的已定义过程来实现.

L4,可预测流程

L5,与时俱进创新流程

— Process capability levels according to ISO/IEC 33020

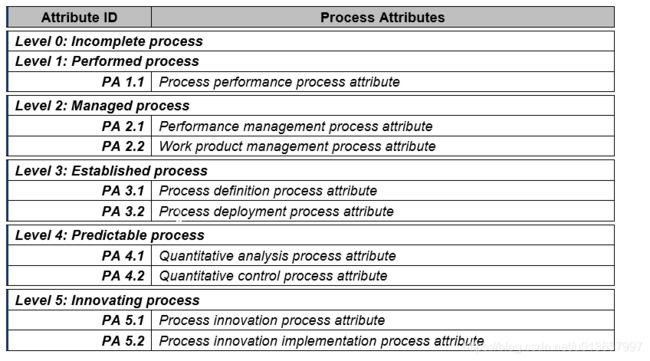

Within this process assessment model, the determination of capability is based upon the nine process attributes (PA) defined in ISO/IEC 33020 and listed in the following Table:

在这个过程评估模型中,能力的定义基于ISO/IEC 33020定义的9个过程属性(PA),如下表:

PA1.1 过程执行流程

PA2.1 执行管理属性

PA2.2 工作产品管理属性

PA3.2 过程部署属性

PA4.1 定量分析属性

PA4.2 定量控制属性

PA5.1 流程创新属性

PA5.2流程创新实施属性

3.2.2 Process attribute rating 过程属性等级

To support the rating of process attributes, the ISO/IEC 33020 measurement framework provides a defined rating scale with an option for refinement, different rating methods and different aggregation methods depending on the class of the assessment (e.g. required for organizational maturity assessments).

Rating scale 等级刻度

Within this process measurement framework, a process attribute is a measureable property of process capability. A process attribute rating is a judgement of the degree of achievement of the process attribute for the assessed process.

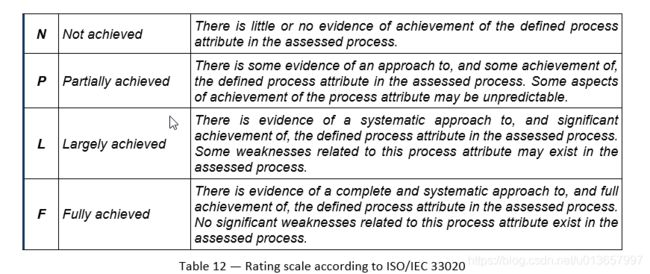

The rating scale is defined by ISO/IEC 33020 as shown in table 12.

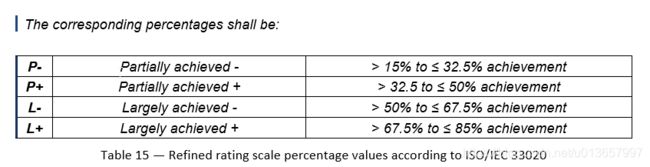

The ordinal scale defined above shall be understood in terms of percentage achievement of a process attribute. The corresponding percentages shall be:

The ordinal scale may be further refined for the measures P and L as defined below.

刻度可进一步划分为如下表

P-

有证据表明,评估过程正在处理定义的过程属性,并且有一些证据表明已经实现了一些已定义的过程属性。 实现此过程属性的许多方面可能是不可预测的。

P+

有证据表明,评估过程正在处理定义的过程属性,并且有一些证据表明已经实现了一些已定义的过程属性。 实现此过程属性的几个方面可能是不可预测的。

L-

有证据表明,评估过程系统地处理定义的过程属性,并且有一些证据表明定义的过程属性明显实现。 评估目标过程中可能存在与此过程属性相关的许多弱点

L+

有证据表明,评估过程系统地处理定义的过程属性,并且有一些证据表明定义的过程属性明显实现。 评估目标过程中可能存在与此过程属性相关的若干弱点.

Rating and aggregation method

分类和聚集方法

ISO/IEC 33020 provides the following definitions:

A process outcome is the observable result of successful achievement of the process purpose. 一个过程的结果应该是成功地满足了过程目标,且这个结果是可见的。

A process attribute outcome is the observable result of achievement of a specified process attribute. 一个过程属性的结果是满足了特定过程属性(PA)的可见结果

Process outcomes and process attribute outcomes may be characterised as an intermediate step to providing a process attribute rating.过程结果和过程属性结果应当被描述成一个中间步骤,用来提供一个过程属性分级 When performing rating, the rating method employed shall be specified relevant to the class of assessment. 当执行分级时,分级方法 应当被恰当的详细说明评估分类。

The following rating methods are defined. The use of rating method may vary according to the class, scope and context of an assessment. The lead assessor shall decide which (if any) rating method to use. The selected rating method(s) shall be specified in the assessment input and referenced in the assessment report.

ISO/IEC 33020 provides the following 3 rating methods:

ISO/IEC 33020 提供下面三种分级方法。

Rating method R1

The approach to process attribute rating shall satisfy the following conditions:

a) Each process outcome of each process within the scope of the assessment shall be characterized for each process instance, based on validated data;

在评估范围中的每个过程的结果应当因每个过程实例被赋予特征,基于被确认的数据。

b) Each process attribute outcome of each process attribute for each process within the scope of the assessment shall be characterised for each process instance, based on validated data;

在评估范围的每个过程中,每个过程属性的每个过程属性结果必须基于有效数据显示每个过程实例的特征。

c) Process outcome characterisations for all assessed process instances shall be aggregated to provide a process performance attribute achievement rating;

必须将要评估的所有流程实例的流程结果的特征制成表格,以评估流程实施属性的实现程度。

d) Process attribute outcome characterisations for all assessed process instances shall be aggregated to provide a process attribute achievement rating.

Rating method R2

The approach to process attribute rating shall satisfy the following conditions:

a) Each process attribute for each process within the scope of the assessment shall be characterized for each process instance, based on validated data;

b) Process attribute characterisations for all assessed process instances shall be aggregated to provide a process attribute achievement rating.

Rating method R3

Process attribute rating across assessed process instances shall be made without aggregation.*

In principle the three rating methods defined in ISO/IEC 33020 depend on

a) whether the rating is made only on process attribute level (Rating method 3 and 2) or – with more level of detail – both on process attribute and process attribute outcome level (Rating method 1); and

b) the type of aggregation ratings across the assessed process instances for each process

If a rating is performed for both process attributes and process attribute outcomes (Rating method 1), the result will be a process performance attribute outcome rating on level 1 and a process attribute achievement rating on higher levels.

Depending on the class, scope and context of the assessment an aggregation within one process (one-dimensional, vertical aggregation), across multiple process instances (one-dimensional, horizontal aggregation) or both (two-dimensional, matrix aggregation) is performed.

ISO/IEC 33020 provides the following examples:

When performing an assessment, ratings may be summarised across one or two dimensions. For example, when rating a

• process attribute for a given process, one may aggregate ratings of the associated process (attribute) outcomes – such an aggregation will be performed as a vertical aggregation (one dimension).

• process (attribute) outcome for a given process attribute across multiple process instances, one may aggregate the ratings of the associated process instances for the given process (attribute) outcome such an aggregation will be performed as a horizontal aggregation (one dimension)

• process attribute for a given process, one may aggregate the ratings of all the process (attribute) outcomes for all the processes instances – such an aggregation will be performed as a matrix aggregation across the full scope of ratings (two dimensions)

The standard defines different methods for aggregation. Further information can be taken from ISO/IEC 33020.