VSC/SMC(一)——基于趋近律的滑模控制(白嫖程序模型)

目录

1.几种典型的趋近律

1.1等速趋近律

1.2指数趋近律

1.3幂次趋近律

1.4一般趋近律

2.控制器设计

2.1被控对象

2.2选取滑膜面

2.3定义跟踪误差

2.4计算控制律

3.Simulink仿真分析

3.1利用S函数编写被控对象

3.2利用S函数编写控制器

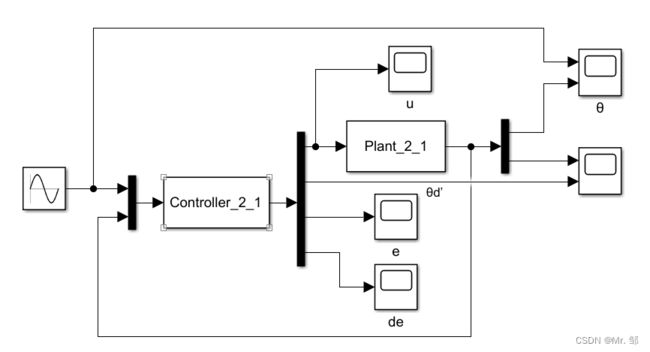

3.3simulink模型

3.4结果分析

1.几种典型的趋近律

1.1等速趋近律

特点:ε表示趋近滑膜面/切换面s = 0的速率;ε越大,则到达切换面越快,但引起的抖动也较大。

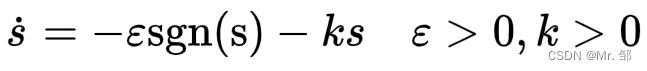

1.2指数趋近律

特点:-ks是指数趋近项,k越大,趋近滑模面速度越大;-εsgn(s)是等速趋近项,是为了消除抖振。所以为了保证快速趋近的同时削弱抖振,应增大k的同时减小ε。一般情况该趋近律使用较多。

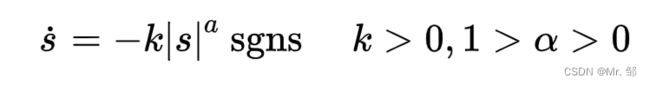

1.3幂次趋近律

1.4一般趋近律

上述四种趋近律均能保证系统从任意初始状态趋向切换面,即做趋近运动:s-->0;满足滑模到达条件:s*s' ≤ 0。

2.控制器设计

2.1被控对象

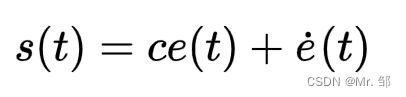

2.2选取滑模面

为满足Huiwitz多项式条件,c > 0。

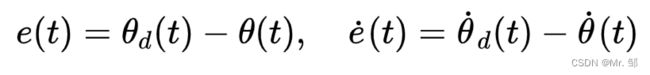

2.3定义跟踪误差

其中:θd(t)为理想位置信号/跟踪信号。

2.4计算控制律

(1)选取指数趋近律:

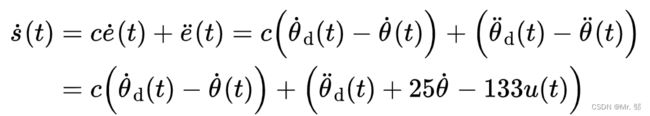

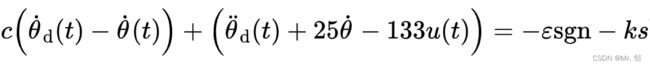

(2)将误差代入选取的滑模面,并进行求导,有:

(3)联立趋近律,即:

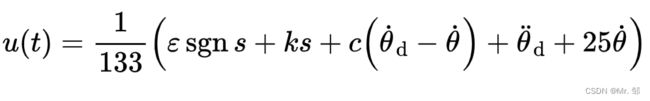

(4)得到控制律/滑模控制器:

3.Simulink仿真分析

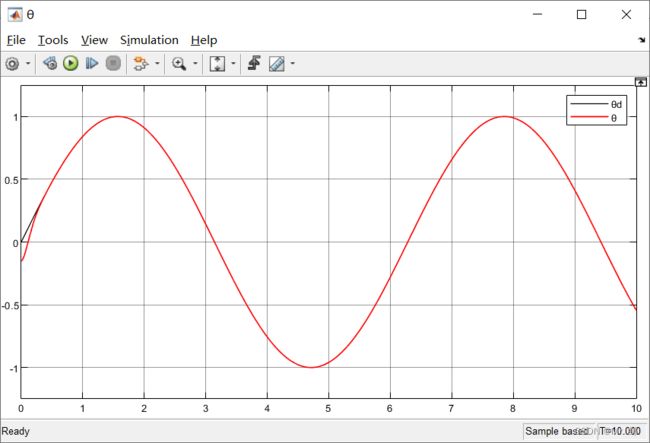

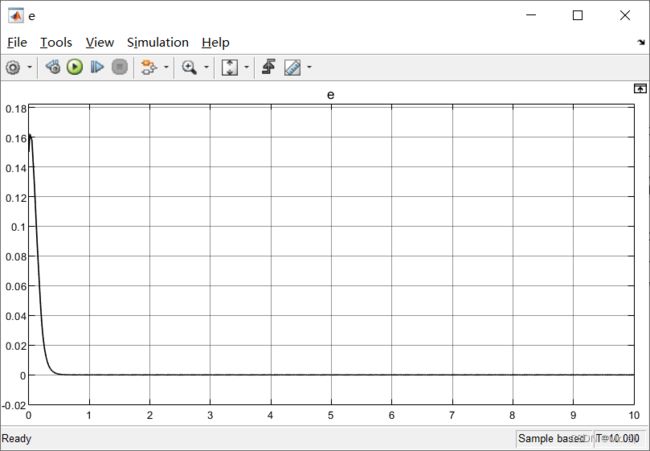

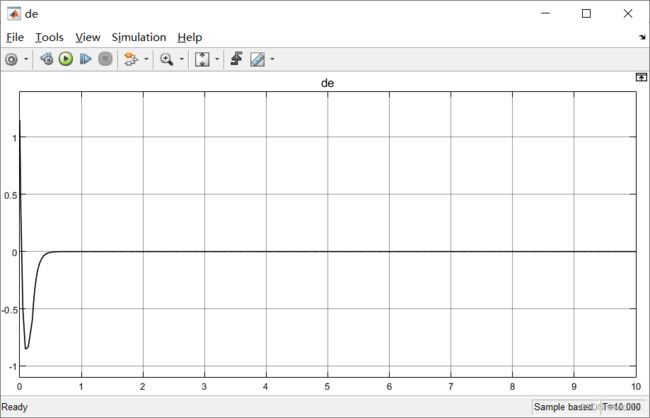

取理想信号θd(t) = sint(t),即跟踪该正弦曲线;选取被控对象状态变量为[θ θ’],初始状态为[-0.15 -0.15]

3.1利用S函数编写被控对象

程序如下:

function [sys,x0,str,ts,simStateCompliance] = Plant_2_1(t,x,u,flag)

switch flag,

case 0,

[sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes;

case 1,

sys=mdlDerivatives(t,x,u);

case 2,

sys=mdlUpdate(t,x,u);

case 3,

sys=mdlOutputs(t,x,u);

case 4,

sys=mdlGetTimeOfNextVarHit(t,x,u);

case 9,

sys=mdlTerminate(t,x,u);

otherwise

DAStudio.error('Simulink:blocks:unhandledFlag', num2str(flag));

end

function [sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes

sizes = simsizes;

sizes.NumContStates = 2;

sizes.NumDiscStates = 0;

sizes.NumOutputs = 2;

sizes.NumInputs = 1;

sizes.DirFeedthrough = 0;%注无直接馈通关系

sizes.NumSampleTimes = 1; % at least one sample time is needed

sys = simsizes(sizes);

x0 = [-0.15;-0.15];%设定状态变量初值

str = [];

ts = [0 0];

simStateCompliance = 'UnknownSimState';

function sys=mdlDerivatives(t,x,u)

theta = x(1);%θ

dtheta = x(2);%θ'

ddtheta = -25*dtheta+133*u;%θ''

sys = [dtheta;ddtheta];%dx

function sys=mdlUpdate(t,x,u)

sys = [];

function sys=mdlOutputs(t,x,u)

sys = x;

function sys=mdlGetTimeOfNextVarHit(t,x,u)

sampleTime = 1; % Example, set the next hit to be one second later.

sys = t + sampleTime;

function sys=mdlTerminate(t,x,u)

sys = [];3.2利用S函数编写控制器

程序如下:

function [sys,x0,str,ts,simStateCompliance] = Controller_2_1(t,x,u,flag)

switch flag,

case 0,

[sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes;

case 1,

sys=mdlDerivatives(t,x,u);

case 2,

sys=mdlUpdate(t,x,u);

case 3,

sys=mdlOutputs(t,x,u);

case 4,

sys=mdlGetTimeOfNextVarHit(t,x,u);

case 9,

sys=mdlTerminate(t,x,u);

otherwise

DAStudio.error('Simulink:blocks:unhandledFlag', num2str(flag));

end

function [sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes

sizes = simsizes;

sizes.NumContStates = 0;

sizes.NumDiscStates = 0;

sizes.NumOutputs = 4;

sizes.NumInputs = 3;

sizes.DirFeedthrough = 1;

sizes.NumSampleTimes = 1; % at least one sample time is needed

sys = simsizes(sizes);

x0 = [];

str = [];

ts = [0 0];

simStateCompliance = 'UnknownSimState';

function sys=mdlDerivatives(t,x,u)

sys = [];

function sys=mdlUpdate(t,x,u)

sys = [];

function sys=mdlOutputs(t,x,u)

thetad = u(1);%理想位置信号θd

dthetad = cos(t);%θd'

ddthetad = -sin(t);%θd''

theta = u(2);

dtheta = u(3);

e = thetad-theta;%跟踪误差

de = dthetad-dtheta;

c = 15;

epsilon = 5;k = 10;%调节参数

s = c*e+de;%滑模面

ut = (epsilon*sign(s)+k*s+c*de+ddthetad+25*dtheta)/133;%控制律/滑模控制器

sys = [ut;dthetad;e;de];

function sys=mdlGetTimeOfNextVarHit(t,x,u)

sampleTime = 1; % Example, set the next hit to be one second later.

sys = t + sampleTime;

function sys=mdlTerminate(t,x,u)

sys = [];3.3simulink模型

3.4结果分析

角度θ

角速度θ'

误差e

误差变化率de

控制输入u

结论:从角位置和角速度可见,该滑膜控制器能实现较好的追踪效果;从误差和误差变化率看,能够通过控制力较快消除误差;但是从控制输入看,出现了很糟糕的抖动,所以后续会提出改进的滑模控制设计。

注:仅为便利自己学习,错误在所难免,如有侵权,请联系删除,有兴趣的学者可以参考学习交流,谢谢!

参考资料:

《滑膜变结构控制MATLAB仿真:基本理论与设计方法第四版》---刘金琨