16路PWM使用方法简单描述

16路PWM使用方法简单描述

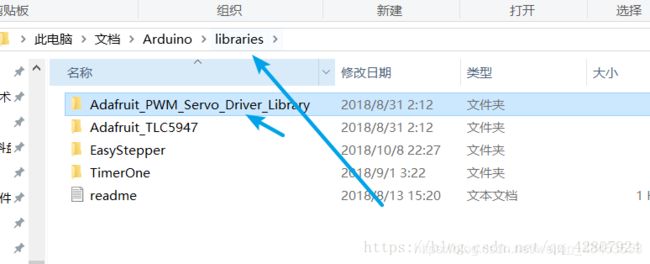

注意!!!下面例子需要用到外部库文件,如果你IDE没有

16路舵机驱动板资料(内含模块级联说明):https://pan.baidu.com/s/1gfhFGDP

把下载文件放入如下位置:

PCA9685模块

PCA9685是16路12位PWM信号发生器,可用于控制舵机、led、电机等设备,采用I2C通信。主机只需要I2C接口即可实现16路舵机控制。

PCA9685的I2C地址默认0x40,如果需要改变地址,则需要将板上A0-A5焊通即可对应的bit置1,此时地址为:0x40+A5:A0。这也意味着主机可以通过I2C地址控制64个PCA9685模块,从而实现最大16*64路舵机控制。

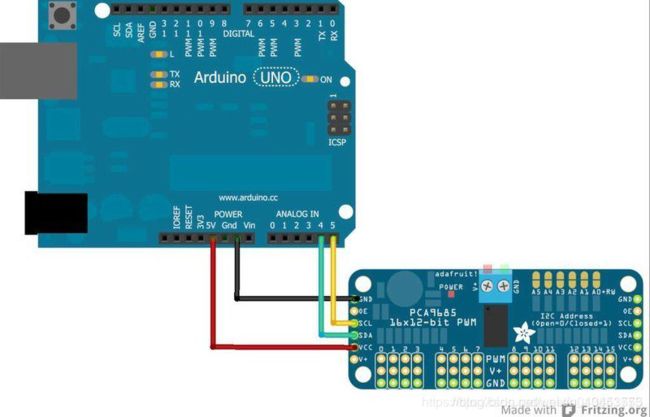

Arduino uno与模块连线

AIN4 ------- SDA

AIN5 ------- SCL

5V -------- VCC

3.3V -------- V+

GND -------- GND

舵机线按照颜色对应接模块0控制口。

V+是舵机电源,试验采用的是9g小舵机,所以也可以用3.3V带动,但是mg995这种大舵机,则需要5V以上才能带动。

VCC是模块的电源,用于PCA9685芯片。

控制程序

舵机的控制一般需要一个20ms的时基脉冲,该脉冲的高电平部分一般为0.5ms~2.5ms范围内的角度控制脉冲部分。以180度角度舵机为例,那么对应的控制关系是这样的:

0.5ms————–0度;

1.0ms————45度;

1.5ms————90度;

2.0ms———–135度;

2.5ms———–180度;

PCA9685可以设置更新频率,时基脉冲周期20ms相当于50HZ更新频率。PCA9685采用12位的寄存器来控制PWM占比,对于0.5ms,相当于0.5/204096=102的寄存器值。以此类推如下:

0.5ms————–0度:0.5/204096 = 102

1.0ms————45度:1/204096 = 204

1.5ms————90度:1.5/204096 = 306

2.0ms———–135度:2/204096 = 408

2.5ms———–180度:2.5/204096 =510

但是实际使用的时候,还是有偏差,除了0度以及180度,其他需要乘以0.915系数。最后的寄存器值如下:

0.5ms————–0度:0.5/204096 = 102

1.0ms————45度:1/204096 = 204 * 0.915 = 187

1.5ms————90度:1.5/204096 = 306 * 0.915 = 280

2.0ms———–135度:2/204096 = 408 * 0.915 = 373

2.5ms———–180度:2.5/20*4096 =510

例子程序1

16路舵机同时转动。原理是定义脉宽最大和最小,通过改变0-15号舵机的脉宽大小实现角度转动:

#include

#include

// called this way, it uses the default address 0x40

////以这种方式调用,它使用默认地址0x40。

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

// you can also call it with a different address you want

//Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver(0x41);

//也可以用不同的地址调用它

/* Depending on your servo make, the pulse width min and max may vary, you want these to be as small/large as possible without hitting the hard stop

for max range. You'll have to tweak them as necessary to match the servos you

have!*/

/*根据你的伺服制作,脉冲宽度最小和最大可能变化,你想要这些尽可能小大而不碰到

硬停止,对于最大范围。你必须调整它们以匹配你的伺服系统!*/

#define SERVOMIN 150 // this is the 'minimum' pulse length count (out of 4096)

//这是“最小”脉冲长度计数(在4096)中

#define SERVOMAX 600 // this is the 'maximum' pulse length count (out of 4096)

//这是“最大”脉冲长度计数(在4096中)

// our servo # counter

//uint8_t servonum = 0;

void setup() {

Serial.begin(9600);

Serial.println("16 channel Servo test!");

pwm.begin();

pwm.setPWMFreq(60); // Analog servos run at ~60 Hz updates

////模拟伺服在60赫兹更新下运行

}

// you can use this function if you'd like to set the pulse length in seconds

// e.g. setServoPulse(0, 0.001) is a ~1 millisecond pulse width. its not precise!

//如果您想以秒为单位设置脉冲长度,则可以使用此函数。

//例如SET伺服脉冲(0,0.001)是一个1毫秒的脉冲宽度。它不是

void setServoPulse(uint8_t n, double pulse) {

double pulselength;//精度浮点数

pulselength = 1000000; // 1,000,000 us per second 每秒100万

pulselength /= 60; // 60 Hz

Serial.print(pulselength); Serial.println(" us per period");

pulselength /= 4096; // 12 bits of resolution 12位分辨率

Serial.print(pulselength); Serial.println(" us per bit");

pulse *= 1000;

pulse /= pulselength;

Serial.println(pulse);

pwm.setPWM(n, 0, pulse);

}

void loop() {

// Drive each servo one at a time

//Serial.println(servonum);

//每次驱动一个伺服驱动器

//串行打印(伺服);

for (uint16_t pulselen = SERVOMIN; pulselen < SERVOMAX; pulselen++) {

pwm.setPWM(0, 0, pulselen);

pwm.setPWM(1, 0, pulselen);

pwm.setPWM(2, 0, pulselen);

pwm.setPWM(3, 0, pulselen);

pwm.setPWM(4, 0, pulselen);

pwm.setPWM(5, 0, pulselen);

pwm.setPWM(6, 0, pulselen);

pwm.setPWM(7, 0, pulselen);

pwm.setPWM(8, 0, pulselen);

pwm.setPWM(9, 0, pulselen);

pwm.setPWM(10, 0, pulselen);

pwm.setPWM(11, 0, pulselen);

pwm.setPWM(12, 0, pulselen);

pwm.setPWM(13, 0, pulselen);

pwm.setPWM(14, 0, pulselen);

pwm.setPWM(15, 0, pulselen);

}

delay(500);

for (uint16_t pulselen = SERVOMAX; pulselen > SERVOMIN; pulselen--) {

pwm.setPWM(0, 0, pulselen);

pwm.setPWM(1, 0, pulselen);

pwm.setPWM(2, 0, pulselen);

pwm.setPWM(3, 0, pulselen);

pwm.setPWM(4, 0, pulselen);

pwm.setPWM(5, 0, pulselen);

pwm.setPWM(6, 0, pulselen);

pwm.setPWM(7, 0, pulselen);

pwm.setPWM(8, 0, pulselen);

pwm.setPWM(9, 0, pulselen);

pwm.setPWM(10, 0, pulselen);

pwm.setPWM(11, 0, pulselen);

pwm.setPWM(12, 0, pulselen);

pwm.setPWM(13, 0, pulselen);

pwm.setPWM(14, 0, pulselen);

pwm.setPWM(15, 0, pulselen);

}

delay(500);

}

例子程序2:

控制程序使用串口通讯接受指令,实现0/45/90/135/180度,总共5种角度的控制。

#include

#include

// 默认地址 0x40

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

#define SERVO_0 102

#define SERVO_45 187

#define SERVO_90 280

#define SERVO_135 373

#define SERVO_180 510

// our servo # counter

uint8_t servonum = 0;

char comchar;

void setup() {

Serial.begin(9600);

Serial.println("8 channel Servo test!");

pwm.begin();

pwm.setPWMFreq(50); // 50HZ更新频率,相当于20ms的周期

delay(10);

}

void loop() {

while(Serial.available()>0){

comchar = Serial.read();//读串口第一个字节

switch(comchar)

{

case '0':

pwm.setPWM(0, 0, SERVO_0);

Serial.write(comchar);

break;

case '1':

pwm.setPWM(0, 0, SERVO_45);

Serial.write(comchar);

break;

case '2':

pwm.setPWM(0, 0, SERVO_90);

Serial.write(comchar);

break;

case '3':

pwm.setPWM(0, 0, SERVO_135);

Serial.write(comchar);

break;

case '4':

pwm.setPWM(0, 0, SERVO_180);

Serial.write(comchar);

break;

default:

Serial.write(comchar);

break;

}

}

}

例子程序3:

#include

#include

//默认地址 0x40

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

//9g舵机 高电平宽度在20ms内通过控制脉冲宽度范围0.5ms~2.5ms

#define SERVOMIN 102 // this is the 'minimum' pulse length count (out of 4096) 0度

#define SERVOMAX 512 // this is the 'maximum' pulse length count (out of 4096) 180度

void setup() {

Serial.begin(9600);

Serial.println("16 channel Servo test!");

pwm.begin();

pwm.setPWMFreq(50); //频率 50Hz,最高60Hz

}

void setServoPulse(uint8_t n, double pulse) {

double pulselength;

pulselength = 1000000; // 1,000,000 us per second

pulselength /= 50; // 50 Hz

Serial.print(pulselength); Serial.println(" us per period");

pulselength /= 4096; // 12 bits of resolution

Serial.print(pulselength); Serial.println(" us per bit");

pulse *= 1000;

pulse /= pulselength;

Serial.println(pulse);

pwm.setPWM(n, 0, pulse);

}

//设置9g舵机角度

void servo_9g_write(uint8_t n,int Angle)

{

double pulse = Angle;

pulse = pulse/90 + 0.5;

setServoPulse(n,pulse);//0到180度映射为0.5到2.5ms

}

void loop()

{

unsigned char serialRead;

if (Serial.available() > 0)

{

serialRead = Serial.read();

servo_9g_write(0,serialRead);//控制第一路度数

}

}