轮胎的魔术公式(Magic Fomula)模型

本篇结合Adams中的TR_rear_pac89.tir文件,介绍一下魔术公式的基本知识。使用魔术公式的轮胎模型主要有Pacejka ’89、Pacejka ’94、MF-Tyre、MF-Swift四种。

1. Pacejka ’89和’94轮胎模型

Pacejka ’89 和’94轮胎模型是以魔术公式主要提出者H. B. Pacejka教授命名的,根据其发布的年限命名。目前有两种直接被ADAMS引用。

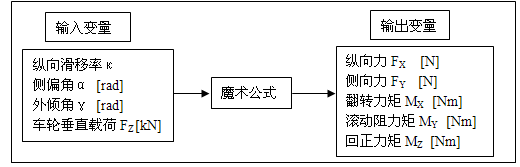

魔术公式是用三角函数的组合公式拟合轮胎试验数据,用一套形式相同的公式就可以完整地表达轮胎的纵向力Fx、侧向力Fy、回正力矩Mz、翻转力矩Mx、阻力矩My以及纵向力、侧向力的联合作用工况,故称为“魔术公式”。

魔术公式的一般表达式为:

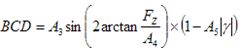

式中Y(x)可以是侧向力,也可以是回正力矩或者纵向力,自变量x可以在不同的情况下分别表示轮胎的侧偏角或纵向滑移率,式中的系数B、C、D依次由轮胎的垂直载荷和外倾角来确定。

Pacejka ’89轮胎模型认为轮胎在垂直、侧向方向上是线性的、阻尼为常量,这在侧向加速度常见范围≤0.4g,侧偏角≤5°的情景下对常规轮胎具有很高的拟合精度。此外,由于魔术公式基于试验数据,除在试验范围的高精度外,甚至在极限值以外一定程度仍可使用,可以对有限工况进行外推且具有较好的置信度。魔术公式正在成为工业标准,即轮胎制造商向整车厂提供魔术公式系数表示的轮胎数据,而不再是表格或图形。

基于魔术公式的轮胎模型还有较好的健壮性,如果没有某一轮胎的试验数据,而使用同类轮胎数据替代仍可取得很好的效果。

图 基于魔术公式的轮胎模型的输入和输出变量

Pacejka ’89轮胎力与力矩的计算

轮胎纵向力计算公式为:

其中X1为纵向力组合自变量:X1=(κ+Sh),κ为纵向滑移率(负值出现在制动态,-100表示车轮抱死)

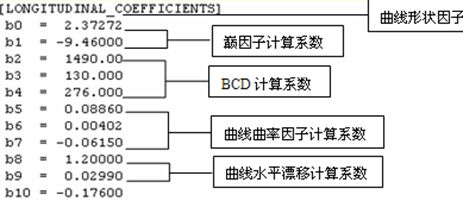

C——曲线形状因子,纵向力计算时取B0值:C = B0

B – 刚度因子:B=BCD/(C×D)

Sv——曲线的垂直方向漂移:Sv=0

图 轮胎属性文件中的纵向力计算系数数据块

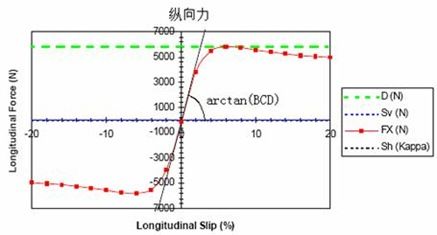

图 Pacejka ’89轮胎纵向力示例

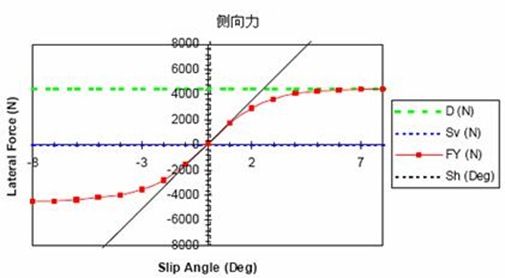

轮胎侧向力计算公式为:

此时的X1为侧向力计算组合自变量:X1=(α+Sh),α为侧偏角

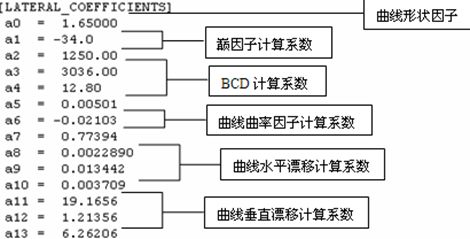

C——曲线形状因子,侧向力计算时取A0值:C = A0

B – 刚度因子:B=BCD/(C×D)

图 轮胎属性文件中的侧向力计算系数数据块

图 Pacejka ’89轮胎纵向力示例

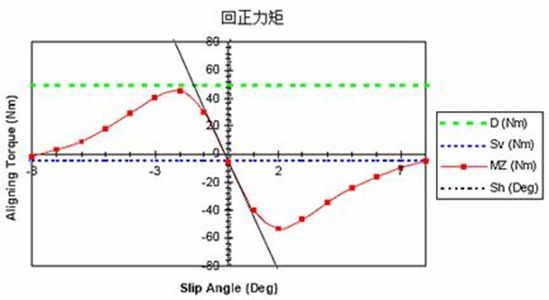

轮胎回正力矩计算公式为:

此时的X1为回正力矩计算组合自变量:X1=(α+Sh),α为侧偏角

C——曲线形状因子,回正力矩计算时取C0值:C = C0

B – 刚度因子:B=BCD/(C×D)

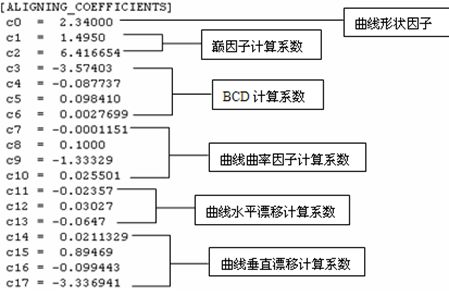

图 轮胎属性文件中的回正力矩计算系数数据块

图 Pacejka ’89轮胎回正力矩示例

侧偏刚度(Lateral Stiffness)

侧偏刚度在Pacejka ’89和’94轮胎模型中假定是一个常量,在轮胎属性文件的参数PARAMETER数据段中通过LATERAL_STIFFNESS语句设定。

侧向形变De:De=Fy /LATERAL_STIFFNESS;

翻转力矩:Mx = -Fz ×De;

纵向力和侧偏角联合作用的回正力矩Mz;

MZ = MZ,MF + Fx×De ,这里MZ,MF为魔术公式计算所得的回正力矩。

滚动阻力(Rolling resistance)

滚动阻力系数RR同样是在轮胎属性文件中规定的具体值,滚动阻力矩My:

My = Fz ×Re×RR

这里:Re为轮胎的滚动半径;RR为滚动阻力系数;Fz垂直载荷(kN)。

平滑过渡(Smoothing)

是否使用平滑过渡也在轮胎属性文件中规定:

² USE_MODE = 1 或 2:关闭平滑过渡

² USE_MODE = 3 或 4:使用平滑过渡

轮胎属性文件TR_rear_pac89.tir全文(示例整车模型MDI_Demo_Vehicle.asy使用的):

$---------------------------------------------------------------------MDI_HEADER

[MDI_HEADER]

FILE_TYPE = 'tir'

FILE_VERSION = 2.0

FILE_FORMAT = 'ASCII'

(COMMENTS)

{comment_string}

'Tire - XXXXXX'

'Pressure - XXXXXX'

'Test Date - XXXXXX'

'Test tire'

'New File Format v2.1'

$--------------------------------------------------------------------------UNITS

[UNITS]

LENGTH = 'mm'

FORCE = 'newton'

ANGLE = 'radians'

MASS = 'kg'

TIME = 'sec'

$--------------------------------------------------------------------------MODEL

[MODEL]

! use mode 1 2 3 4

! -------------------------------------------

! smoothing X X

! combined X X

!

PROPERTY_FILE_FORMAT = 'PAC89' 轮胎模型关键词

FUNCTION_NAME = 'TYR900' 解算器函数

USE_MODE = 4.0 平滑过渡模式

$----------------------------------------------------------------------DIMENSION

[DIMENSION]

UNLOADED_RADIUS = 340.6 轮胎自由半径

WIDTH = 255.0 轮胎宽度

ASPECT_RATIO = 0.35 高宽比

$----------------------------------------------------------------------PARAMETER

[PARAMETER]

VERTICAL_STIFFNESS = 310.0 纵向刚度系数

VERTICAL_DAMPING = 3.1 纵向阻尼系数

LATERAL_STIFFNESS = 190.0 侧偏刚度

ROLLING_RESISTANCE = 0.0 滚动阻力系数

$-----------------------------------------------------------LATERAL_COEFFICIENTS

[LATERAL_COEFFICIENTS]

a0 = 1.65000

a1 = -34.0

a2 = 1250.00

a3 = 3036.00

a4 = 12.80

a5 = 0.00501

a6 = -0.02103

a7 = 0.77394

a8 = 0.0022890

a9 = 0.013442

a10 = 0.003709

a11 = 19.1656

a12 = 1.21356

a13 = 6.26206

$-------------------------------------------------------------------longitudinal

[LONGITUDINAL_COEFFICIENTS]

b0 = 2.37272

b1 = -9.46000

b2 = 1490.00

b3 = 130.000

b4 = 276.000

b5 = 0.08860

b6 = 0.00402

b7 = -0.06150

b8 = 1.20000

b9 = 0.02990

b10 = -0.17600

$----------------------------------------------------------------------aligning

[ALIGNING_COEFFICIENTS]

c0 = 2.34000

c1 = 1.4950

c2 = 6.416654

c3 = -3.57403

c4 = -0.087737

c5 = 0.098410

c6 = 0.0027699

c7 = -0.0001151

c8 = 0.1000

c9 = -1.33329

c10 = 0.025501

c11 = -0.02357

c12 = 0.03027

c13 = -0.0647

c14 = 0.0211329

c15 = 0.89469

c16 = -0.099443

c17 = -3.336941

注意:属性文件中的单位数据块[UNITS]不用于魔术公式的系数a,b,c。

2. 代码

MF5.2的实现代码:

void RPacejka::CalcMF52() // Pacejka MF5.2 (~2006) { rfloat Fx0,Dx,Cx,Ex,Bx,dfz,Fz0,Fz0_der; // Nominal load, adapted nominal load rfloat kx,k,mux,sign_kx; rfloat Shx,Svx,Kx,gamma,gamma_x; rfloat Fzn; // Fz in Newtons rfloat tmp; // // Global // k=slipPercentage*0.01f; // Slip ratio Fzn=Fz*1000.0f; Fz0=fz0; //4500; Fz0_der=lfz0*Fz0; dfz=(Fzn-Fz0_der)/Fz0_der; gamma=camber/RR_RAD2DEG; // // Fx (pure slip) // Shx=(phx1+phx2*dfz)*lhx; Svx=Fzn*(pvx1+pvx2*dfz)*lvx*lmux; kx=k+Shx; if(kx<0)sign_kx=-1.0f; else sign_kx=1.0f; gamma_x=gamma*lgax; Cx=pcx1*lcx; mux=(pdx1+pdx2*dfz)*(1.0f-pdx3*gamma_x*gamma_x)*lmux; // Different in Pac2006 Ex=(pex1+pex2*dfz+pex3*dfz*dfz)*(1.0f-pex4*sign_kx)*lex; // Limiter on Ex (eq 23) if(Ex>1.0f)Ex=1.0f; Dx=mux*Fzn; Kx=Fzn*(pkx1+pkx2*dfz)*expf(pkx3*dfz)*lkx; // K=BCD (=stiffness) // Low velocity trouble tmp=Cx*Dx; if(fabs(tmp)<0.001f) Bx=Kx/(tmp+0.001f); else Bx=Kx/tmp; tmp=Bx*kx; Fx0=Dx*sinf(Cx*atanf(tmp-Ex*(tmp-atanf(tmp))))+Svx; // // Fy // rfloat Fy0,Dy,Cy,Ey,By; rfloat localMuy; rfloat Shy,Svy,Ky; rfloat say,sign_alpha_y; rfloat gamma_y; rfloat alpha; alpha=sideSlip/RR_RAD2DEG; gamma_y=gamma*lgay; Cy=pcy1*lcy; localMuy=(pdy1+pdy2*dfz)*(1.0f-pdy3*gamma_y*gamma_y)*lmuy; Dy=localMuy*Fzn; Ky=pky1*Fz0_der*sinf(2.0f*atanf(Fzn/(pky2*Fz0_der)))*(1.0f-pky3*fabs(gamma_y))*lfz0*lky; // =BCD=stiffness at slipangle 0 tmp=Cy*Dy; if(fabs(tmp)<0.001f) By=Ky/(tmp+0.001f); else By=Ky/tmp; Shy=(phy1+phy2*dfz)*lhy+phy3*gamma_y; Svy=Fzn*((pvy1+pvy2*dfz)*lvy+(pvy3+pvy4*dfz)*gamma_y)*lmuy; say=alpha+Shy; if(say<0)sign_alpha_y=-1.0f; else sign_alpha_y=1.0f; Ey=(pey1+pey2*dfz)*(1.0f-(pey3+pey4*gamma_y)*sign_alpha_y)*ley; // Limiter on Ey (eq 35) if(Ey>1.0f)Ey=1.0f; // Lateral base force tmp=By*say; Fy0=Dy*sinf(Cy*atanf(tmp-Ey*(tmp-atan(tmp))))+Svy; // // Mz // rfloat Mzr; rfloat t0,Dt,Ct,Bt,alpha_t,Et,gamma_z; rfloat Sht,Shf; rfloat Br,R0; rfloat alpha_r,Dr; const float lr=1.0f; // Not found in paper at lambda section R0=r0; gamma_z=gamma*lgaz; Sht=qhz1+qhz2*dfz+(qhz3+qhz4*dfz)*gamma_z; alpha_t=alpha+Sht; // Avoid division by zero if(fabs(Ky)<0.001f) if(Ky<0)Ky=-0.001f; else Ky=0.001f; Shf=Shy+Svy/Ky; alpha_r=alpha+Shf; Bt=(qbz1+qbz2*dfz+qbz3*dfz*dfz)*(1.0f+qbz4*gamma_z+qbz5*fabs(gamma_y))*lky/lmuy; // Pac2006 adds gamma_y^2 dependence (qbz6) Ct=qcz1; Dt=Fzn*(qdz1+qdz2*dfz)*(1.0f+qdz3*gamma_z+qdz4*gamma_z*gamma_z)*(R0/Fz0_der)*lt; // lt=lamba_t? Et=(qez1+qez2*dfz+qez3*dfz*dfz)*(1.0f+(qez4+qez5*gamma_z)*(2.0f/3.14159265f)*atanf(Bt*Ct*alpha_t)); // <=1 // Clamp Et (eq 51) if(Et>1.0f)Et=1.0f; Br=qbz9*lky/lmuy+qbz10*By*Cy; // Preferred qbz9=0 tmp=Bt*alpha_t; t0=Dt*cosf(Ct*atanf(tmp-Et*(tmp-atan(tmp))))*cosf(alpha); // t_alpha_t in the paper Dr=Fzn*((qdz6+qdz7*dfz)*lr+(qdz8+qdz9*dfz)*gamma_z)*R0*lmuy; // *cosf(alpha_t) for Pac2006 (in MF52 this is still in Mzr=... below) Mzr=Dr*cosf(Ct*atanf(Br*alpha_r))*cos(alpha); // last cos(alpha) is cos(alpha_t) in Pac2006 // No combined aligning moment Mz=-t0*Fy0+Mzr; // // Combined slip // // Combine (page 30+) // Longitudinal float Shxa,Exa,Cxa,Bxa,alpha_s,Gxa0,Gxa; Shxa=rhx1; Exa=rex1+rex2*dfz; Cxa=rcx1; Bxa=rbx1*cosf(atan(rbx2*k))*lxal; // +rbx3*gammaStar*gammaStar) (Pac2006) alpha_s=alpha+Shxa; Gxa0=cos(Cxa*atan(Bxa*Shxa-Exa*(Bxa*Shxa-atan(Bxa*Shxa)))); if(fabs(Gxa0)>D3_EPSILON) Gxa=cos(Cxa*atan(Bxa*alpha_s-Exa*(Bxa*alpha_s-atan(Bxa*alpha_s))))/Gxa0; else Gxa=0; // Or 1 for super grip? Fx=Gxa*Fx0; // Lateral float Dvyk,Svyk,Shyk,Eyk,Cyk,Byk,ks,Gyk0,Gyk; Dvyk=muy*Fz*(rvy1+rvy2*dfz+rvy3*gamma)*cosf(atanf(rvy4*alpha)); Svyk=Dvyk*sin(rvy5*atan(rvy6*k))*lvyka; Shyk=rhy1+rhy2*dfz; Eyk=rey1+rey2*dfz; Cyk=rcy1; Byk=rby1*cosf(atanf(rby2*(alpha-rby3)))*lyka; ks=k+Shyk; Gyk0=cosf(Cyk*atanf(Byk*Shyk-Eyk*(Byk*Shyk-atanf(Byk*Shyk)))); Gyk=cosf(Cyk*atanf(Byk*ks-Eyk*(Byk*ks-atanf(Byk*ks))))/Gyk0; Fy=Gyk*Fy0+Svyk; // Aligning torque float alpha_r_eq,alpha_t_eq,Mzr,Fy_der; float sign_alpha_t,sign_alpha_r; float kk,s,t; if(alpha_t>=0)sign_alpha_t=1.0f; else sign_alpha_t=-1.0f; if(alpha_r>=0)sign_alpha_r=1.0f; else sign_alpha_r=-1.0f; kk=Kx/Ky; kk=(kk*kk*k*k); // kk^2*k^2 alpha_r_eq=sqrtf(alpha_r*alpha_r+kk)*sign_alpha_r; alpha_t_eq=sqrtf(alpha_t*alpha_t+kk)*sign_alpha_t; s=(ssz1+ssz2*(Fy/Fz0_der)+(ssz3+ssz4*dfz)*gamma)*R0*ls; Mzr=Dr*cosf(atanf(Br*alpha_r_eq))*cosf(alpha); Fy_der=Fy-Svyk; // New pneumatic trail tmp=Bt*alpha_t_eq; t=Dt*cosf(Ct*atanf(tmp-Et*(tmp-atanf(tmp))))*cosf(alpha); // Add all aligning forces Mz=-t*Fy_der+Mzr+s*Fx; // Postprocess; negate for Racer?! Fy=-Fy; Mz=-Mz; // Static results latStiffness=-By*Cy*Dy; // There's that '-' again for lateral force (Fy) longStiffness=Bx*Cx*Dx; }

MF6.1实现代码:

rfloat RPacejka::CalcMz96() // Calculates aligning moment { rfloat Mz; rfloat B,C,D,E,Sh,Sv; rfloat FzSquared; // Calculate derived coefficients FzSquared=Fz*Fz; C=c0; D=c1*FzSquared+c2*Fz; E=(c7*FzSquared+c8*Fz+c9)*(1.0f-c10*fabs(camber)); if((C>-D3_EPSILON&&C<D3_EPSILON)|| (D>-D3_EPSILON&&D<D3_EPSILON)) { B=99999.0f; } else { B=((c3*FzSquared+c4*Fz)*(1-c6*fabs(camber))*expf(-c5*Fz))/(C*D); } Sh=c11*camber+c12*Fz+c13; Sv=(c14*FzSquared+c15*Fz)*camber+c16*Fz+c17; Mz=D*sinf(C*atanf(B*(1.0f-E)*(sideSlip+Sh)+ E*atanf(B*(sideSlip+Sh))))+Sv; return Mz; }

// Fx - longitudinal rfloat RPacejka::CalcFx96() // Pacejka96 model // Calculates longitudinal force (Fx) // From G. Genta's book, page 63 // Note that the units are inconsistent: // Fz is in kN // slipRatio is in percentage (=slipRatio*100=slipPercentage) // camber and slipAngle are in degrees // Resulting forces are better defined: // Fx, Fy are in N // Mz is in Nm { rfloat B,C,D,E; rfloat Fx; rfloat Sh,Sv; rfloat uP; rfloat FzSquared; // Calculate derived coefficients FzSquared=Fz*Fz; C=b0; uP=b1*Fz+b2; D=uP*Fz; // Avoid div by 0 if((C>-D3_EPSILON&&C<D3_EPSILON) || (D>-D3_EPSILON&&D<D3_EPSILON)) { B=99999.0f; } else { B=((b3*FzSquared+b4*Fz)*expf(-b5*Fz))/(C*D); } E=b6*FzSquared+b7*Fz+b8; Sh=b9*Fz+b10; Sv=b11*Fz+b12; // Notice that product BCD is the longitudinal tire stiffness longStiffness=B*C*D; // *RR_RAD2DEG; // RR_RAD2DEG == *360/2PI // Remember the max longitudinal force (where sin(...)==1) maxForce.x=D+Sv; // Calculate result force Fx=D*sinf(C*atanf(B*(1.0f-E)*(slipPercentage+Sh)+E*atanf(B*(slipPercentage+Sh))))+Sv; return Fx; }

// Fy - lateral rfloat RPacejka::CalcFy96() // Pacejka 96 // Calculates lateral force // Note that B*C*D is the cornering stiffness, and // Sh and Sv account for ply steer and conicity forces { rfloat B,C,D,E; rfloat Fy; rfloat Sh,Sv; rfloat uP; // Calculate derived coefficients C=a0; uP=a1*Fz+a2; D=uP*Fz; E=a6*Fz+a7; // Avoid div by 0 if((C>-D3_EPSILON&&C<D3_EPSILON) || (D>-D3_EPSILON&&D<D3_EPSILON)) { B=99999.0f; } else { if(a4>-D3_EPSILON&&a4<D3_EPSILON) { B=99999.0f; } else { // Notice that product BCD is the lateral stiffness (=cornering) latStiffness=a3*sinf(2*atanf(Fz/a4))*(1.0f-a5*fabs(camber)); B=latStiffness/(C*D); } } Sh=a8*camber+a9*Fz+a10; Sv=(a111*Fz+a112)*camber*Fz+a12*Fz+a13; // Remember maximum lateral force maxForce.y=D+Sv; // Calculate result force Fy=D*sinf(C*atanf(B*(1.0f-E)*(sideSlip+Sh)+ E*atanf(B*(sideSlip+Sh))))+Sv; return Fy; }