小作文--流程图(练习1)

【【雅思写作】带你打破小作文‘流程图’的传说】 https://www.bilibili.com/video/BV1QP411Q7Gh/?share_source=copy_web&vd_source=78768d4ae65c35ff26534bbaa8afc267

雅思小作文-流程图, 看这一篇就够了! - 冯凯文的文章 - 知乎 https://zhuanlan.zhihu.com/p/35868880

1. 段落框架

开头段:一句话改写题目

概述段:两句话——可以写大概有多少个步骤, 涉及哪些部分, 开始结束分别是什么, 等等

描述段1:按顺序写(看图说话),客观的图文信息交代出来,加入衔接词(副词,代词,同意转换),阶段信息强化(目的是让读者知道你写到哪个地方了,不能一直然后然后)

描述段2:同描述段1

2.写作要点

时态:一般现在时

语态:被动语态(因为很多流程步骤我们是不清楚谁做的,要客观描述会用到很多“被动”的描述)

衔接词:

- The diagram shows the different stages in the process of ...

- the diagram shows how ... works

- the diagram explains the way in which sth. are made for ...

- the diagram illustrate the way in which sth. are made and how it is then used in the process of ...

- the diagram illustrates the basic principles of ...

- a complex process with no fewer than ... different parties involved and there are ... different steps until (sth. happen)

- the process requires ...

- there are ... stages in the process, beginning with ... and culminating in ...

- Overall, sth. pass through ... stages before ...

- the process of doing sth uses a number of tools

- the production of ... requires ...

- in the first stage of ...

- The first step is ...

- To begin, ...

- following this, ...

- Next, ...

- the resulting sth. is ... in order to ...

- In the subsequent stage, ...

- Finally, ...

- the final product is afterwards ...

- the first part of ... shows ...

- the second part of ... shows ...

- regarding the second diagram, ...

- at that point, ...

- in turn

- Once sth. have been done, ...

- ... does not ... until ...

- After sth have been done, ...

- at the end of ... is/are ...

- sth. can either happen as A, or B

- ... by either A or B

- ... makes up xx% of the ...

- the main ingredients consist of ...

3. 练习一篇

开头段

The flow diagram illustrates how to made sugar from sugar cance.

概述段

It is noticeable that there are seven distinct stages in the manufacturing process for making sugar from sugar cane. These mainly include growing and harvesting sugar canes, purifying and evaporating juice, and drying and cooling sugar crystals.

描述段1

At the first stage in the process, sugar canes are planted, and it takes 12 to 18 months to grow. Next, these sugar canes are harvested either by machines or farmers to be prepared for further manufacturing.

描述段2

At the third step show on the diagram, the sugar canes are crushed by a big crusher to produce juice. Then, a limestone filter is used to purify the sugar cane juice which is subsequently delivered into a big evaporater, the juice is heated to be turned into syrup which is more condensed. At stage six, a machine called "Centrifuge" is utilised to separate sugar crystals from the syrup. These sugar crystals are then dried and cooled in a big container, and sugar is finally produced.

开头段

The flow diagram explains the way in which bricks are made for the construction industry.

概述段

There are eight stages in the process, beginning with extracting raw material, clay, and culminating in making a delivery.

描述段1

At the first stage in the process, caly, which is the main ingredient for making bricks, is collected by using a large digger. It is then placed on a metal grid where clay is broken up into smaller pieces and transported to the next stage via a roller machine. Followong this, sand and water as the other two major ingredients are added, and the mixture is turned into bricks either by using a wire cutter or a mould.

描述段2

In the subsequent stage, bricks are moved to a drying oven in which they stayed for between one to two days to dry. Next, dry brics go into a kiln where they are heated at a temperature ranging from a low of 200 to a high of 1300. This is followed by a cooling process in a cooling chamber for approximately two to three days. The final product is afterwards packed and delivered for use in building sites.

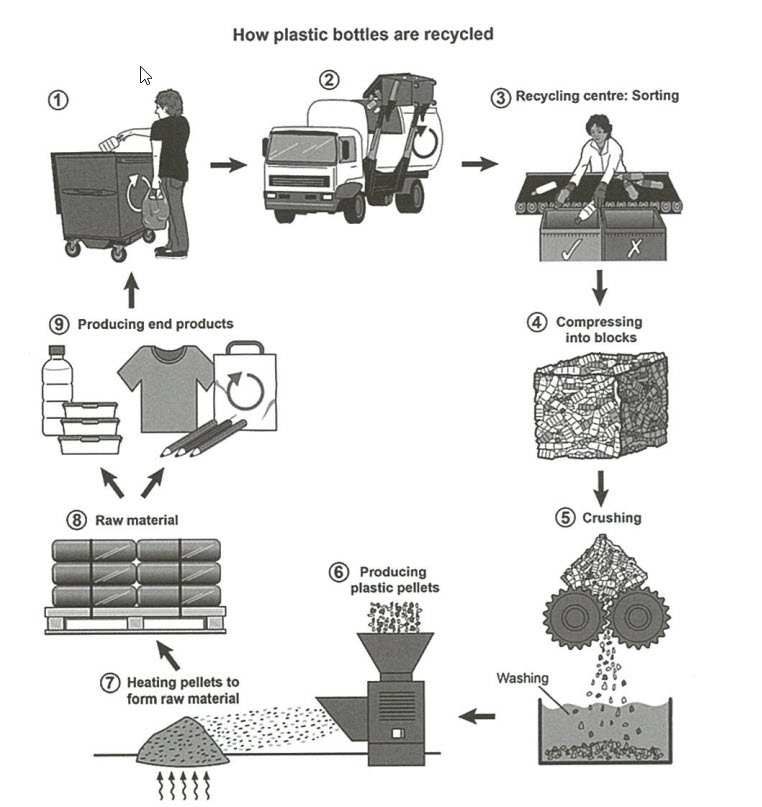

开头段

The flow diagram illustrates the way in which plastic bottles are recycled.

The flow diagram illustrates how plastic bottles are recycled.

The flow diagram illustrates how to recycle plastic bottles.

概述段

It is noticeable that there are nine distinct stages in the recycling process. These mainly include collecting and sorting plastic-bottles, compressing into blocks, and producing and heating pellets.

It is noticeable that there are nine distinct stages in plastic-bottle recycling. Roughly speaking, plastic bottles are collected, sorted, broken down, and finally made into new products.

There are nine stages in the process, beginning with collecting plastic-bottles from daily life, and culminating in making products.

描述段1

At the first stage in the process, plastic bottles from home, business, and other sites are collected. They are then transported by truck to the recycling center for the further sorting process. At the center, plastic-bottles are manually sorted and separated from irrelevant items, with recyclable bottles set apart for the following procedure. Those bottles are subsequently compressed into blocks and then crushed into small pieces, which are later washed in a container to remove all residues.

描述段2

At the six step show on the diagram, these cleaned fragments are sent into a machine to produce plastic pellets, and these pellets are heated afterward so that they become the raw materials for new products. Finally, end products are molded in various forms: plastic bottles, pencils, shirts, bags, and others. Those products then the market to fulfill their missions in people's daily lives, potentially to be recycled someday in the future.

开头段

The diagram on the left explains the process in which cement is made while the diagram on the right illustrates how concrete is made.

概述段

It is noticeable that the production of cement and concrete appear to be fairly simple processes. And cement is the raw material of concrete.

描述段1

As presented in the left dirgram, the first stage in cement production is to put two substances, limestone and clay, through a crusher to create a powder. This powder then goes through a mixer and is then heated in a rotating heater. Once the powder has gone through the mixer and heater, it is ground and the cement is packed into bags.

描述段2

The diagram on the right hand side tells us that concrete is a mixture of four ingredients in differing proportions. Cement makes up 15% of the mixture, water constitutes 10%, sand 25%, and gravel (i.e. small stones) 50%. These ingredients are mixed in a rotating concrete mixer to make concrete.