7-4、S加减速转动实现【51单片机控制步进电机-TB6600系列】

摘要:本节介绍实现步进电机S曲线运动的代码

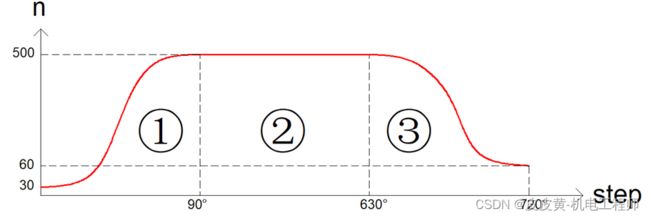

一、目标功能

实现步进电机转动总角度720°,其中加减速各90°

加速段:加速类型:S曲线

加速角度:角度为90°

起步速度:30RPM,

终止速度:500RPM

匀速段:匀速角度:角度为540°

匀速速度:500RPM

减速段:减速类型:S曲线

减速角度:角度为90°

起步速度:500RPM

终止速度:60RPM

二、生成器计算

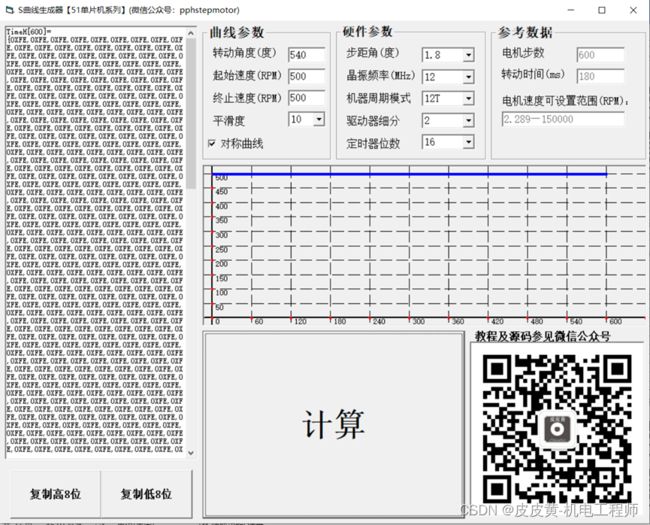

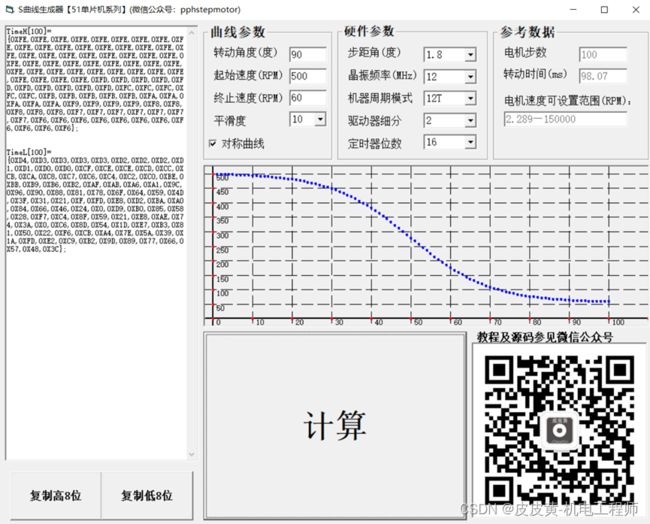

加速参数计算

匀速参数计算,主要计算电机步数

减速参数计算

三、程序代码

//加速、匀速、减速步数

#define step0 100

#define step1 600

#define step2 100

unsigned int n=0;//步数计数变量

unsigned int flag=0;//标志位,0:加速段 1:匀速段 2:减速段

//加速段90°,30RPM-500RPM

const unsigned char code TimeH0[100]={0XEC,0XEC,0XEC,0XED,0XED,0XED,0XEE,0XEE,0XEE,0XEF,0XEF,0XF0,0XF0,0XF1,0XF1,0XF2,0XF2,0XF3,0XF3,0XF4,0XF4,0XF5,0XF5,0XF6,0XF6,0XF7,0XF7,0XF8,0XF8,0XF8,0XF9,0XF9,0XFA,0XFA,0XFA,0XFB,0XFB,0XFB,0XFB,0XFC,0XFC,0XFC,0XFC,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE};

const unsigned char code TimeL0[100]={0X78,0XB4,0XF5,0X3B,0X86,0XD6,0X2A,0X84,0XE4,0X48,0XB1,0X1F,0X92,0X9,0X83,0X1,0X82,0X5,0X8A,0X10,0X96,0X1C,0XA0,0X24,0XA5,0X23,0X9E,0X15,0X88,0XF7,0X61,0XC5,0X25,0X80,0XD5,0X26,0X71,0XB7,0XF9,0X36,0X6E,0XA3,0XD3,0X0,0X29,0X4F,0X71,0X91,0XAE,0XC9,0XE1,0XF8,0XC,0X1F,0X2F,0X3F,0X4D,0X59,0X65,0X6F,0X79,0X82,0X8A,0X91,0X97,0X9D,0XA2,0XA7,0XAB,0XAF,0XB3,0XB6,0XB9,0XBC,0XBE,0XC1,0XC2,0XC4,0XC6,0XC7,0XC9,0XCA,0XCB,0XCC,0XCD,0XCE,0XCE,0XCF,0XD0,0XD0,0XD1,0XD1,0XD2,0XD2,0XD2,0XD3,0XD3,0XD3,0XD3,0XD4};

//减速段90°,500RPM-60RPM

const unsigned char code TimeH2[100]={0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFE,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFD,0XFC,0XFC,0XFC,0XFC,0XFC,0XFB,0XFB,0XFB,0XFB,0XFB,0XFA,0XFA,0XFA,0XFA,0XFA,0XF9,0XF9,0XF9,0XF9,0XF8,0XF8,0XF8,0XF8,0XF8,0XF7,0XF7,0XF7,0XF7,0XF7,0XF7,0XF7,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6,0XF6};

const unsigned char code TimeL2[100]={0XD4,0XD3,0XD3,0XD3,0XD3,0XD2,0XD2,0XD2,0XD1,0XD1,0XD0,0XD0,0XCF,0XCE,0XCE,0XCD,0XCC,0XCB,0XCA,0XC8,0XC7,0XC6,0XC4,0XC2,0XC0,0XBE,0XBB,0XB9,0XB6,0XB2,0XAF,0XAB,0XA6,0XA1,0X9C,0X96,0X90,0X88,0X81,0X78,0X6F,0X64,0X59,0X4D,0X3F,0X31,0X21,0XF,0XFD,0XE8,0XD2,0XBA,0XA0,0X84,0X66,0X46,0X24,0X0,0XD9,0XB0,0X85,0X58,0X28,0XF7,0XC4,0X8F,0X59,0X21,0XE8,0XAE,0X74,0X3A,0X0,0XC6,0X8D,0X54,0X1D,0XE7,0XB3,0X81,0X50,0X22,0XF6,0XCB,0XA4,0X7E,0X5A,0X39,0X1A,0XFD,0XE2,0XC9,0XB2,0X9D,0X89,0X77,0X66,0X57,0X48,0X3C};

void main()

{

while(1)

{

}

}

//定时器0中断程序

void time0_int() interrupt 1

{

//产生一个脉冲

PUL=1;

_nop_();_nop_();nop_();nop_();

PUL=0;

n++;//步数加1

switch (flag)//判断运动状态

{

case 0://加速段

{

if(n==step0)//加速段完成

{

n=0;

flag=1;

TH0=TimeH2[0];//装载定时寄存器匀速段初值

TL0=TimeL2[0];

}

else

{

TH0=TimeH0[n];//装载定时寄存器加速段初值

TL0=TimeL0[n];

}

}break;

case 1://匀速段

{

TH0=TimeH2[0];//装载定时寄存器匀速段初值

TL0=TimeL2[0];

if(n==step1)//匀速段完成

{

n=0;

flag=2;

TH0=TimeH2[n];//装载定时寄存器减速段初值

TL0=TimeL2[n];

}

}break;

case 2://减速段

{

if(n==step2)//减速段完成

{

n=0;

flag=0;

TR0=0; //电机停止

}

else

{

TH0=TimeH2[n];//装载定时寄存器减速段初值

TL0=TimeL2[n];

}

}break;

default:

break;

}

}

四.总结

通过上述计算,完成S曲线加减速运动。通过调整匀速运动的角度,加减速过程不变,可以实现总转动角度的变化,适用于总转角需要变化且需要较高速度的情况,并且满足总转角应大于加减速转角之和。

对于大多数情况,加减速的过程可以合并,即用S加速的逆过程去实现减速,可以实现代码的简化