cordic算法详解

作者:善良的一休君

来源:CSDN

原文:https://blog.csdn.net/qq_39210023/article/details/77456031

版权声明:本文为博主原创文章,转载请附上博文链接!

---------------------

目前,学习与开发FPGA的程序员们大多使用的是Verilog HDL语言(以下简称为Verilog),关于Verilog的诸多优点一休哥就不多介绍了,在此,我们将重点放在Verilog的运算操作上。

我们都知道,在Verilog中,运算一般分为逻辑运算(与或非等)与算术运算(加减乘除等)。而在一开始学习Verilog时,老司机一定会提醒我们,“切记,千万别用‘/’除、‘%’取模(有的也叫取余)和‘**’幂。”这话说的不无道理,因为这三个运算是不可综合的。但,需清楚理解的是,不可综合的具体意思为不能综合为简单的模块,当我们在程序中调用了这些运算时,‘/’除和‘%’取模在Quartus软件中是可以综合的,因此可以正常调用运行,但是会消耗一些逻辑资源,而且会产生延时,即这两个运算的处理时间会很长,可能会大于时序控制时钟的单周期时间。此时呢,我们会建议你调用IP核来实现运算操作,虽然这样也会消耗许多逻辑资源,但产生的延时相对较小满足了你基本的需求。

问题好像迎刃而解了,可是仔细一想,除了这些运算,我们还剩下什么?对呀,三角函数,反三角函数,对数函数,指数函数呢,这些函数我们在高中就学习了的呀,难道在FPGA中就没有用武之地吗?有人会说,查找表呗,首先将某个运算的所有可能的输入与输出对一一罗列出来,然后放进Rom中,然后根据输入查表得到输出。这个方法虽然有效的避免了延时问题,却是一个十分消耗资源的方法,不适合资源紧张的设计。那么,就真的没有办法了吗?

答案就是咱们今天的标题了,CORDIC,而且CORDIC是一个比较全能的算法,通过这一原理,我们可以实现三角函数,反三角函数,对数函数,指数函数等多种运算。接下来,一休哥就带领大家来学习CORDIC的原理吧。(题外话:请相信一休哥,本文不会让你感到太多痛苦~)

本文将分三个小部分来展开介绍:

1、CORDIC的基本原理介绍

2、CORDIC的具体操作流程介绍

3、CORDIC的旋转模式——Verilog仿真

本文涉及到的全部资料链接:

链接:http://pan.baidu.com/s/1gfrJzMj 密码:x92u

一、CORDIC的基本原理介绍

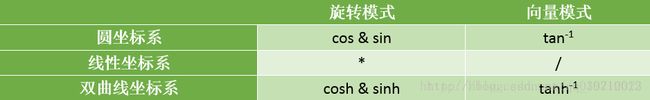

CORDIC算法是一个“化繁为简”的算法,将许多复杂的运算转化为一种“仅需要移位和加法”的迭代操作。CORDIC算法有旋转和向量两个模式,分别可以在圆坐标系、线性坐标系和双曲线坐标系使用,从而可以演算出8种运算,而结合这8种运算也可以衍生出其他许多运算。下表展示了8种运算在CORDIC算法中实现的条件。

首先,我们先从旋转模式下的圆坐标系讲起,这也是CORDIC方法最初的用途。

1、CORDIC的几何原理介绍

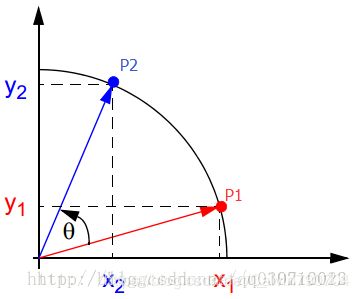

假设在xy坐标系中有一个点P1(x1,y1),将P1点绕原点旋转θ角后得到点P2(x2,y2)。

于是可以得到P1和P2的关系。

x2 = x1cosθ – y1sinθ = cosθ(x1 – y1tanθ)

y2 = y1cosθ + x1sinθ = cosθ(y1 +x1tanθ)

以上就是CORDIC的几何原理部分,而我们该如何深入理解这个几何原理的真正含义呢?

从原理中,我们可以知道,当已知一个点P1的坐标,并已知该点P1旋转的角度θ,则可以根据上述公式求得目标点P2的坐标。然后,麻烦来了,我们需要用FPGA去执行上述运算操作,而FPGA的Verilog语言根本不支持三角函数运算。因此,我们需要对上述式子进行简化操作,将复杂的运算操作转换为一种单一的“迭代位移”算法。那么,接下来我们介绍优化算法部分。

2、CORDIC的优化算法介绍

我们先介绍算法的优化原理:将旋转角θ细化成若干分固定大小的角度θi,并且规定θi满足tanθi = 2^(-i),因此∑θi的值在[-99.7°,99.7°]范围内,如果旋转角θ超出此范围,则运用简单的三角运算操作即可(加减π)。

然后我们需要修改几何原理部分的假设,假设在xy坐标系中有一个点P0(x0,y0),将P0点绕原点旋转θ角后得到点Pn(xn,yn)。

于是可以得到P0和Pn的关系。

xn = x0cosθ – y0sinθ = cosθ(x0 – y0tanθ)

yn = y0cosθ + x0sinθ = cosθ(y0 + x0tanθ)

然后,我们将旋转角θ细化成θi,由于每次的旋转角度θi是固定不变的(因为满足tanθi = 2^(-i)),如果一直朝着一个方向旋转则∑θi一定会超过θ(如果θ在[-99.7°,99.7°]范围内)。因此我们需要对θi设定一个方向值di。如果旋转角已经大于θ,则di为-1,表示下次旋转为顺时针,即向θ靠近;如果旋转角已经小于θ,则di为1,表示下次旋转为逆时针,即也向θ靠近。然后我们可以得到每次旋转的角度值diθi,设角度剩余值为zi+1,则有zi+1 = zi - diθi,其中z0为θ。如此随着i的增大,角度剩余值zi+1将会趋近于0,此时运算结束。(注:可以发现,di与zi的符号位相同)

第一次旋转θ0,d0为旋转方向:

x1 = cosθ0(x0 – d0y0tanθ0)

y1 = cosθ0(y0 + d0x0tanθ0)

第二次旋转θ1,d1为旋转方向:

x2 = cosθ1(x1 – d1y1tanθ1) = cosθ1cosθ0(x0 – d0y0tanθ0 – d1y0tanθ1 – d1d0 x0tanθ1 tanθ0)

y2 = cosθ1(y1 + d1x1tanθ1) = cosθ1cosθ0(y0 + d0x0tanθ0 + d1x0tanθ1 – d1d0y0tanθ1 tanθ0)

大家可能已经发现了,在我们旋转的过程中,式子里一直会有tanθi和cosθi,而每次都可以提取出cosθi。虽然我们的FPGA无法计算tanθi,但我们知道tanθi = 2^(-i),因此可以执行和tanθi效果相同的移位操作 2^(-i)来取代tanθi。而对于cosθi,我们可以事先全部提取出来,然后等待迭代结束之后(角度剩余值zi+1趋近于0,一般当系统设置最大迭代次数为16时zi+1已经很小了),然后计算出∏cosθi的值即可。

总结一下:

迭代公式有三:

xi+1 = xi – d iy i 2^(-i),提取了cosθi, 2^(-i)等效替换了tanθi之后

yi+1 = yi + d ix i 2^(-i),提取了cosθi, 2^(-i)等效替换了tanθi之后

zi+1 = zi - diθi

其中i从0开始迭代,假设当i = n-1时,zn趋近于0,迭代结束。然后对结果乘上∏cosθi(i从0至n-1),于是得到点Pn(xn∏cosθi,yn∏cosθi),此时的点Pn就近似等于之前假设中的点Pn(xn,yn)了,所以此时的点Pn同样满足之前假设得到的公式:

xn∏cosθi = x0cosθ – y0sinθ

yn∏cosθi = y0cosθ + x0sinθ

由于i从0至n-1,所以上式可以转化成下式:

xn = 1/∏cosθi(x0cosθ – y0sinθ),(其中i从0至n-1)

yn = 1/∏cosθi(y0cosθ + x0sinθ),(其中i从0至n-1)

注意:上式中的xn,yn是经过迭代后的结果,而不是之前假设中的点Pn(xn,yn)。了解这点是十分重要的。

根据高中学的三角函数关系,可以知道cosθi = 1/[(1+tan2θi)^0.5] = 1/[(1+2^(-2i))^0.5],而1/[(1+2^(-2i))^0.5]的极值为1,因此我们可以得出一个结论:当i的次数很大时,∏cosθi的值趋于一个常数。

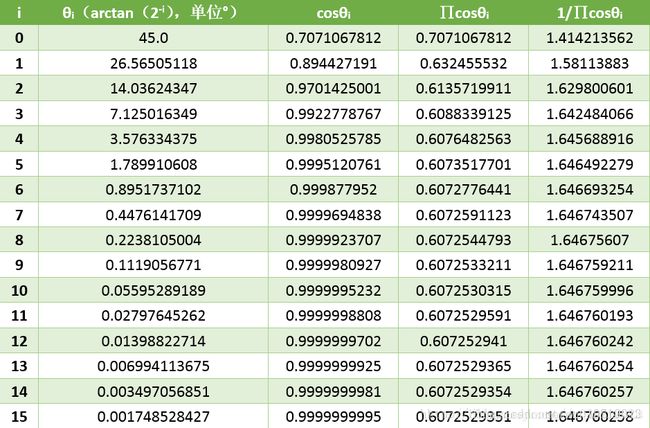

关于如何计算∏cosθi的代码如下所示:

close all;

clear;

clc;

% 初始化

die = 16;%迭代次数

jiao = zeros(die,1);%每次旋转的角度

cos_value = zeros(die,1);%每次旋转的角度的余弦值

K = zeros(die,1);%余弦值的N元乘积

K_1 = zeros(die,1);%余弦值的N元乘积的倒数

for i = 1 : die

a = 2^(-(i-1));

jiao(i) = atan(a);

cos_value(i) = cos(jiao(i));

if( i == 1)

K(i) = cos_value(i);

K_1(i) = 1/K(i);

else

K(i) = K(i-1)*cos_value(i);

K_1(i) = 1/K(i);

end

end

jiao = vpa(rad2deg(jiao)*256,10)

cos_value = vpa(cos_value,10)

K = vpa(K,10)

K_1 = vpa(K_1,10)

这里写图片描述

从上表也可以看出,当迭代次数为16,i=15时,cosθi的值已经非常趋近于1了,∏cosθi的值则约等于0.607253,1/∏cosθi为1.64676。所以当迭代次数等于16时,通过迭代得到的点Pn坐标已经非常接近之前假设中的点Pn。所以,当迭代次数等于16时,这个式子是成立的。

xn = 1/∏cosθi(x0cosθ – y0sinθ),(其中i从0至n-1)

yn = 1/∏cosθi(y0cosθ + x0sinθ),(其中i从0至n-1)

此时,已知条件有三个x0、y0和θ。通过16次迭代,我们可以得到xn和yn。而式中的∏cosθi是个随i变化的值,我们可以预先将其值存入系统中。

然后,我们人为设置x0 = ∏cosθi,y0 = 0,则根据等式,xn = cosθ,yn = sinθ。其中1/∏cosθi的值我们也同样预先存入系统中。如此,我们就实现了正弦和余弦操作了。

二、CORDIC的具体操作流程介绍

1、CORDIC的旋转模式

由于算法较复杂,一休哥再总结一些具体的操作流程。

1、 设置迭代次数为16,则x0 = 0.607253,y0 = 0,并输入待计算的角度θ,θ在[-99.7°,99.7°]范围内。

2、 根据三个迭代公式进行迭代,i从0至15:

xi+1 = xi – d iy i2-i

yi+1 = yi + d ix i2-i

zi+1 = zi - diθi

注:z0 = θ,di与zi同符号。

3、 经过16次迭代计算后,得到的x16 和y16分别为cosθ和sinθ。

至此,关于CORDIC的三角函数cosθ和sinθ的计算原理讲解结束。

关于CORDIC算法计算三角函数cosθ和sinθ的MATLAB代码如下所示:

close all;

clear;

clc;

% 初始化

die = 16;%迭代次数

x = zeros(die+1,1);

y = zeros(die+1,1);

z = zeros(die+1,1);

x(1) = 0.607253;%初始设置

z(1) = pi/4;%待求角度θ

%迭代操作

for i = 1:die

if z(i) >= 0

d = 1;

else

d = -1;

end

x(i+1) = x(i) - d*y(i)*(2^(-(i-1)));

y(i+1) = y(i) + d*x(i)*(2^(-(i-1)));

z(i+1) = z(i) - d*atan(2^(-(i-1)));

end

cosa = vpa(x(17),10)

sina = vpa(y(17),10)

c = vpa(z(17),10)

2、CORDIC的向量模式

讲完了旋转模式后,我们接着讲讲向量模式下的圆坐标系。

在这里,我们需从头来过了,假设在xy坐标系中有一个点P0(x0,y0),将P0点绕原点旋转θ角后得到点Pn(xn,0),θ在[-99.7°,99.7°]范围内。

于是可以得到P0和Pn的关系:

xn = x0cosθ – y0sinθ = cosθ(x0 – y0tanθ)

yn = y0cosθ + x0sinθ = cosθ(y0 + x0tanθ) = 0

如何得到Pn(xn,yn)一直是我们的目标。而此时,我们还是列出那几个等式:

根据三个迭代公式进行迭代,i从0至15:

xi+1 = xi – d iy i2-i

yi+1 = yi + d ix i2-i

zi+1 = zi - diθi

不过此时我们尝试改变初始条件:

设置迭代次数为16,则x0 = x,y0 = y,z0 = 0,di与yi的符号相反。表示,经过n次旋转,使Pn靠近x轴。

因此,当迭代结束之后,Pn将近似接近x轴,此时yn = 0,可知旋转了θ,即zn = θ = arctan(y/x)。

而

xn = 1/∏cosθi(x0cosθ – y0sinθ),(其中i从0至n-1)

yn = 1/∏cosθi(y0cosθ + x0sinθ),(其中i从0至n-1)

因此,可得ycosθ + xsinθ = 0,

xn = 1/∏cosθi(xcosθ – ysinθ) = 1/∏cosθi{ [ (xcosθ – ysinθ)^2]^(1/2)}

= 1/∏cosθi{ [ x2cos2θ + y2sin2θ – 2xysinθcosθ]^(1/2)}

= 1/∏cosθi{ [ x2cos2θ + y2sin2θ + y2 cos2θ + x2sin2θ]^(1/2)}

= 1/∏cosθi{ [ x2 + y2]^(1/2)}

由上可以知道,我们通过迭代,就算出了反正切函数zn = θ = arctan(y/x),以及向量OP0(x,y)的长度 d = xn * ∏cosθi。

关于反正切函数,一休哥要多啰嗦几句了,由于θ在[-99.7°,99.7°]范围内,所以我们输入向量OP0(x,y)时,需要保证其在第一、四象限。

关于CORDIC算法计算反三角函数arctanθ的MATLAB代码如下所示:

close all;

clear;

clc;

% 初始化

die = 16;%迭代次数

x = zeros(die+1,1);

y = zeros(die+1,1);

z = zeros(die+1,1);

x(1) = 100;%初始设置

y(1) = 200;%初始设置

k = 0.607253;%初始设置

%迭代操作

for i = 1:die

if y(i) >= 0

d = -1;

else

d = 1;

end

x(i+1) = x(i) - d*y(i)*(2^(-(i-1)));

y(i+1) = y(i) + d*x(i)*(2^(-(i-1)));

z(i+1) = z(i) - d*atan(2^(-(i-1)));

end

d = vpa(x(17)*k,10)

a = vpa(y(17),10)

c = vpa(rad2deg(z(17)),10)

三、CORDIC的旋转模式——Verilog仿真

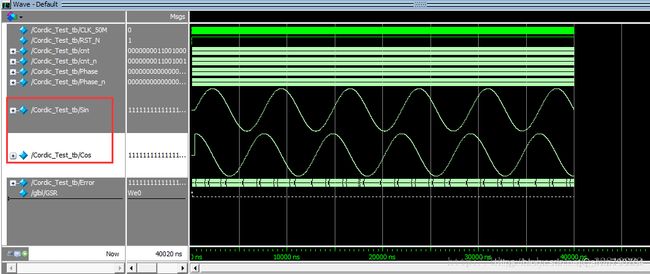

一休哥在编写CORDIC算法时,采用了16级流水线,仿真效果十分明显。以下是顶层文件的代码。

为了避免浮点运算,为了满足精度要求,一休哥对每个变量都放大了2^16倍,并且引入了有符号型reg和算术右移。

关于Verilog代码的编写,一休哥已经不想多说了,因为代码是完全符合我之前所讲的CORDIC的原理与MATLAB仿真代码。相信大家在看完本文的前两个部分之后,对Verilog的理解应该不是难事儿。

module Cordic_Test

(

CLK_50M,RST_N,

Phase,

Sin,Cos,Error

);

input CLK_50M;

input RST_N;

input [31:0] Phase;

output [31:0] Sin;

output [31:0] Cos;

output [31:0] Error;

`define rot0 32'd2949120 //45度*2^16

`define rot1 32'd1740992 //26.5651度*2^16

`define rot2 32'd919872 //14.0362度*2^16

`define rot3 32'd466944 //7.1250度*2^16

`define rot4 32'd234368 //3.5763度*2^16

`define rot5 32'd117312 //1.7899度*2^16

`define rot6 32'd58688 //0.8952度*2^16

`define rot7 32'd29312 //0.4476度*2^16

`define rot8 32'd14656 //0.2238度*2^16

`define rot9 32'd7360 //0.1119度*2^16

`define rot10 32'd3648 //0.0560度*2^16

`define rot11 32'd1856 //0.0280度*2^16

`define rot12 32'd896 //0.0140度*2^16

`define rot13 32'd448 //0.0070度*2^16

`define rot14 32'd256 //0.0035度*2^16

`define rot15 32'd128 //0.0018度*2^16

parameter Pipeline = 16;

parameter K = 32'h09b74; //K=0.607253*2^16,32'h09b74,

reg signed [31:0] Sin;

reg signed [31:0] Cos;

reg signed [31:0] Error;

reg signed [31:0] x0=0,y0=0,z0=0;

reg signed [31:0] x1=0,y1=0,z1=0;

reg signed [31:0] x2=0,y2=0,z2=0;

reg signed [31:0] x3=0,y3=0,z3=0;

reg signed [31:0] x4=0,y4=0,z4=0;

reg signed [31:0] x5=0,y5=0,z5=0;

reg signed [31:0] x6=0,y6=0,z6=0;

reg signed [31:0] x7=0,y7=0,z7=0;

reg signed [31:0] x8=0,y8=0,z8=0;

reg signed [31:0] x9=0,y9=0,z9=0;

reg signed [31:0] x10=0,y10=0,z10=0;

reg signed [31:0] x11=0,y11=0,z11=0;

reg signed [31:0] x12=0,y12=0,z12=0;

reg signed [31:0] x13=0,y13=0,z13=0;

reg signed [31:0] x14=0,y14=0,z14=0;

reg signed [31:0] x15=0,y15=0,z15=0;

reg signed [31:0] x16=0,y16=0,z16=0;

reg [ 1:0] Quadrant [Pipeline:0];

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x0 <= 1'b0;

y0 <= 1'b0;

z0 <= 1'b0;

end

else

begin

x0 <= K;

y0 <= 32'd0;

z0 <= Phase[15:0] << 16;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x1 <= 1'b0;

y1 <= 1'b0;

z1 <= 1'b0;

end

else if(z0[31])

begin

x1 <= x0 + y0;

y1 <= y0 - x0;

z1 <= z0 + `rot0;

end

else

begin

x1 <= x0 - y0;

y1 <= y0 + x0;

z1 <= z0 - `rot0;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x2 <= 1'b0;

y2 <= 1'b0;

z2 <= 1'b0;

end

else if(z1[31])

begin

x2 <= x1 + (y1 >>> 1);

y2 <= y1 - (x1 >>> 1);

z2 <= z1 + `rot1;

end

else

begin

x2 <= x1 - (y1 >>> 1);

y2 <= y1 + (x1 >>> 1);

z2 <= z1 - `rot1;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x3 <= 1'b0;

y3 <= 1'b0;

z3 <= 1'b0;

end

else if(z2[31])

begin

x3 <= x2 + (y2 >>> 2);

y3 <= y2 - (x2 >>> 2);

z3 <= z2 + `rot2;

end

else

begin

x3 <= x2 - (y2 >>> 2);

y3 <= y2 + (x2 >>> 2);

z3 <= z2 - `rot2;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x4 <= 1'b0;

y4 <= 1'b0;

z4 <= 1'b0;

end

else if(z3[31])

begin

x4 <= x3 + (y3 >>> 3);

y4 <= y3 - (x3 >>> 3);

z4 <= z3 + `rot3;

end

else

begin

x4 <= x3 - (y3 >>> 3);

y4 <= y3 + (x3 >>> 3);

z4 <= z3 - `rot3;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x5 <= 1'b0;

y5 <= 1'b0;

z5 <= 1'b0;

end

else if(z4[31])

begin

x5 <= x4 + (y4 >>> 4);

y5 <= y4 - (x4 >>> 4);

z5 <= z4 + `rot4;

end

else

begin

x5 <= x4 - (y4 >>> 4);

y5 <= y4 + (x4 >>> 4);

z5 <= z4 - `rot4;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x6 <= 1'b0;

y6 <= 1'b0;

z6 <= 1'b0;

end

else if(z5[31])

begin

x6 <= x5 + (y5 >>> 5);

y6 <= y5 - (x5 >>> 5);

z6 <= z5 + `rot5;

end

else

begin

x6 <= x5 - (y5 >>> 5);

y6 <= y5 + (x5 >>> 5);

z6 <= z5 - `rot5;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x7 <= 1'b0;

y7 <= 1'b0;

z7 <= 1'b0;

end

else if(z6[31])

begin

x7 <= x6 + (y6 >>> 6);

y7 <= y6 - (x6 >>> 6);

z7 <= z6 + `rot6;

end

else

begin

x7 <= x6 - (y6 >>> 6);

y7 <= y6 + (x6 >>> 6);

z7 <= z6 - `rot6;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x8 <= 1'b0;

y8 <= 1'b0;

z8 <= 1'b0;

end

else if(z7[31])

begin

x8 <= x7 + (y7 >>> 7);

y8 <= y7 - (x7 >>> 7);

z8 <= z7 + `rot7;

end

else

begin

x8 <= x7 - (y7 >>> 7);

y8 <= y7 + (x7 >>> 7);

z8 <= z7 - `rot7;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x9 <= 1'b0;

y9 <= 1'b0;

z9 <= 1'b0;

end

else if(z8[31])

begin

x9 <= x8 + (y8 >>> 8);

y9 <= y8 - (x8 >>> 8);

z9 <= z8 + `rot8;

end

else

begin

x9 <= x8 - (y8 >>> 8);

y9 <= y8 + (x8 >>> 8);

z9 <= z8 - `rot8;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x10 <= 1'b0;

y10 <= 1'b0;

z10 <= 1'b0;

end

else if(z9[31])

begin

x10 <= x9 + (y9 >>> 9);

y10 <= y9 - (x9 >>> 9);

z10 <= z9 + `rot9;

end

else

begin

x10 <= x9 - (y9 >>> 9);

y10 <= y9 + (x9 >>> 9);

z10 <= z9 - `rot9;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x11 <= 1'b0;

y11 <= 1'b0;

z11 <= 1'b0;

end

else if(z10[31])

begin

x11 <= x10 + (y10 >>> 10);

y11 <= y10 - (x10 >>> 10);

z11 <= z10 + `rot10;

end

else

begin

x11 <= x10 - (y10 >>> 10);

y11 <= y10 + (x10 >>> 10);

z11 <= z10 - `rot10;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x12 <= 1'b0;

y12 <= 1'b0;

z12 <= 1'b0;

end

else if(z11[31])

begin

x12 <= x11 + (y11 >>> 11);

y12 <= y11 - (x11 >>> 11);

z12 <= z11 + `rot11;

end

else

begin

x12 <= x11 - (y11 >>> 11);

y12 <= y11 + (x11 >>> 11);

z12 <= z11 - `rot11;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x13 <= 1'b0;

y13 <= 1'b0;

z13 <= 1'b0;

end

else if(z12[31])

begin

x13 <= x12 + (y12 >>> 12);

y13 <= y12 - (x12 >>> 12);

z13 <= z12 + `rot12;

end

else

begin

x13 <= x12 - (y12 >>> 12);

y13 <= y12 + (x12 >>> 12);

z13 <= z12 - `rot12;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x14 <= 1'b0;

y14 <= 1'b0;

z14 <= 1'b0;

end

else if(z13[31])

begin

x14 <= x13 + (y13 >>> 13);

y14 <= y13 - (x13 >>> 13);

z14 <= z13 + `rot13;

end

else

begin

x14 <= x13 - (y13 >>> 13);

y14 <= y13 + (x13 >>> 13);

z14 <= z13 - `rot13;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x15 <= 1'b0;

y15 <= 1'b0;

z15 <= 1'b0;

end

else if(z14[31])

begin

x15 <= x14 + (y14 >>> 14);

y15 <= y14 - (x14 >>> 14);

z15 <= z14 + `rot14;

end

else

begin

x15 <= x14 - (y14 >>> 14);

y15 <= y14 + (x14 >>> 14);

z15 <= z14 - `rot14;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

x16 <= 1'b0;

y16 <= 1'b0;

z16 <= 1'b0;

end

else if(z15[31])

begin

x16 <= x15 + (y15 >>> 15);

y16 <= y15 - (x15 >>> 15);

z16 <= z15 + `rot15;

end

else

begin

x16 <= x15 - (y15 >>> 15);

y16 <= y15 + (x15 >>> 15);

z16 <= z15 - `rot15;

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

Quadrant[0] <= 1'b0;

Quadrant[1] <= 1'b0;

Quadrant[2] <= 1'b0;

Quadrant[3] <= 1'b0;

Quadrant[4] <= 1'b0;

Quadrant[5] <= 1'b0;

Quadrant[6] <= 1'b0;

Quadrant[7] <= 1'b0;

Quadrant[8] <= 1'b0;

Quadrant[9] <= 1'b0;

Quadrant[10] <= 1'b0;

Quadrant[11] <= 1'b0;

Quadrant[12] <= 1'b0;

Quadrant[13] <= 1'b0;

Quadrant[14] <= 1'b0;

Quadrant[15] <= 1'b0;

Quadrant[16] <= 1'b0;

end

else

begin

Quadrant[0] <= Phase[17:16];

Quadrant[1] <= Quadrant[0];

Quadrant[2] <= Quadrant[1];

Quadrant[3] <= Quadrant[2];

Quadrant[4] <= Quadrant[3];

Quadrant[5] <= Quadrant[4];

Quadrant[6] <= Quadrant[5];

Quadrant[7] <= Quadrant[6];

Quadrant[8] <= Quadrant[7];

Quadrant[9] <= Quadrant[8];

Quadrant[10] <= Quadrant[9];

Quadrant[11] <= Quadrant[10];

Quadrant[12] <= Quadrant[11];

Quadrant[13] <= Quadrant[12];

Quadrant[14] <= Quadrant[13];

Quadrant[15] <= Quadrant[14];

Quadrant[16] <= Quadrant[15];

end

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

begin

Cos <= 1'b0;

Sin <= 1'b0;

Error <= 1'b0;

end

else

begin

Error <= z16;

case(Quadrant[16])

2'b00: //if the Phase is in first Quadrant,the Sin(X)=Sin(A),Cos(X)=Cos(A)

begin

Cos <= x16;

Sin <= y16;

end

2'b01: //if the Phase is in second Quadrant,the Sin(X)=Sin(A+90)=CosA,Cos(X)=Cos(A+90)=-SinA

begin

Cos <= ~(y16) + 1'b1;//-Sin

Sin <= x16;//Cos

end

2'b10: //if the Phase is in third Quadrant,the Sin(X)=Sin(A+180)=-SinA,Cos(X)=Cos(A+180)=-CosA

begin

Cos <= ~(x16) + 1'b1;//-Cos

Sin <= ~(y16) + 1'b1;//-Sin

end

2'b11: //if the Phase is in forth Quadrant,the Sin(X)=Sin(A+270)=-CosA,Cos(X)=Cos(A+270)=SinA

begin

Cos <= y16;//Sin

Sin <= ~(x16) + 1'b1;//-Cos

end

endcase

end

end

endmodule

以下是testbench文件代码

`timescale 1 ps/ 1 ps

module Cordic_Test_tb;

// Inputs

reg CLK_50M;

reg RST_N;

reg [15:0] cnt;

reg [15:0] cnt_n;

reg [31:0] Phase;

reg [31:0] Phase_n;

wire [31:0] Sin;

wire [31:0] Cos;

wire [31:0] Error;

// Instantiate the Unit Under Test (UUT)

Cordic_Test uut

(

.CLK_50M (CLK_50M ),

.RST_N (RST_N ),

.Phase (Phase ),

.Sin (Sin ),

.Cos (Cos ),

.Error (Error )

);

initial

begin

#0 CLK_50M = 1'b0;

#10000 RST_N = 1'b0;

#10000 RST_N = 1'b1;

#10000000 $stop;

end

always #10000

begin

CLK_50M = ~CLK_50M;

end

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

cnt <= 1'b0;

else

cnt <= cnt_n;

end

always @ (*)

begin

if(cnt == 16'd359)

cnt_n = 1'b0;

else

cnt_n = cnt + 1'b1;

end

//生成相位0-359度,Phase[17:16]为相位的象限,Phase[15:10]为相位的值

always @ (posedge CLK_50M or negedge RST_N)

begin

if(!RST_N)

Phase <= 1'b0;

else

Phase <= Phase_n;

end

always @ (*)

begin

if(cnt <= 16'd90)

Phase_n = cnt;

else if(cnt > 16'd90 && cnt <= 16'd180)

Phase_n = {2'd01,cnt - 16'd90};

else if(cnt > 16'd180 && cnt <= 16'd270)

Phase_n = {2'd10,cnt - 16'd180};

else if(cnt > 16'd270)

Phase_n = {2'd11,cnt - 16'd270};

end

endmodule

最后来一张效果图,可以发现,我们的16级流水线已经正常的运行起来了,由于我们仿真输入的相位值为0-359度循环,因此sin和cos也循环了~~~