案例4:三个储罐串联的液位控制

(\Program Files\ShellGlobalSolutions\PCTP\Tutorial\SMOCPro\Tutorial4_TanksInSeries..wsp)

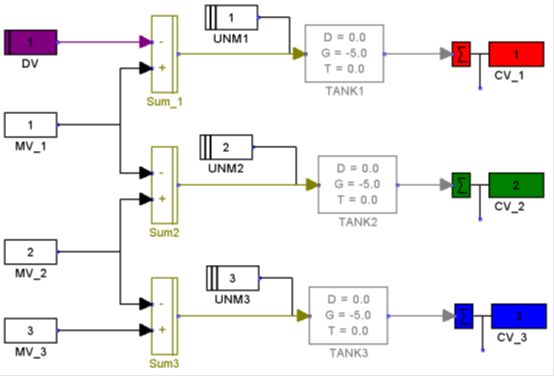

本例中所考虑的应用是此前研究中发现情况的延伸。考虑3个相等尺寸容器串联的一个流程。控制目标是保证3个容器的液位(CVs)对规定的用户指定设定点保持敏感。为此,可将三个流量速率阀门的OP(MVs)作为操作变量。第一个容器的进料流量速率是一个测量干扰,不适用于操作的(DV)。下图为流程原理图。

流程模型

下图为用于该系统的流程模型。注意模型中的彩色块与仿真曲线具有相同的颜色编码,紫色的是DV,红色的是CV1,绿色的是CV2,最后的蓝色是CV3。控制模型编译后控制周期为1.0分钟。

控制器设计

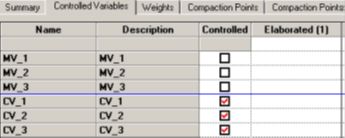

正在研究的控制器应用将所有的液位(CVs)定义在一个子控制器下。

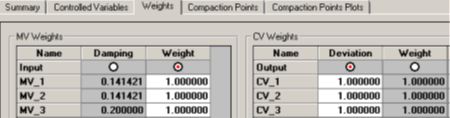

我们为所有的MVs和CVs指定共同的权重:

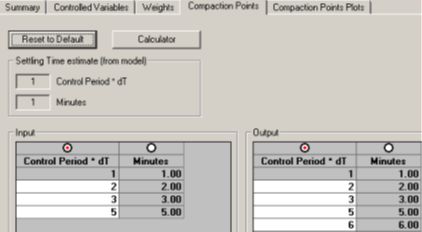

最后,如下图所示,与前面的单容器例子一样,我们将这个控制器的MV时域由其默认值100 × dT修改为5 × dT。同时记住要使用Calculator功能,这样CV预测时域就会相应的自动调整。

该控制器既没有经济函数也没有静态约束。

仿真

在这个例子中,我们研究了一系列的实验以建立在多个竞争斜坡CVs存在的情况下正确地指定CV优先次序的重要性。当控制器在残缺模式下运行时,正确地执行说明显得尤其重要。

本例中所要介绍的所有仿真的运行初始条件指定如下。POV的起始条件为:

|步骤| 部分 |变量| 属性| 新值|

| ------------- |:-------------:| -----:|

|1 |POV |All CVs |脉冲因子| 0.9|

|1 |POV |All CVs |操作点 |50.00|

基本上我们所有的液位CVs初始值都为50,并且都具有较高的Impulse Factor。然后,CV的起始条件为:

|步骤 |部分| 变量 |属性 |新值|

| ------------- |:-------------:| -----:|

|1 |CV |CV_1| Setrange High |60.00|

|1 |CV| CV_1| Setrange Low |60.00|

|1 |CV| CV_2| Setrange High |60.00|

|1| CV |CV_2| Setrange Low |50.00|

|1 |CV| CV_3 |Setrange High |40.00|

|1| CV |CV_4| Setrange Low |40.00|

液位所需设定值有60、50和40,分别表示为Level 1,Level 2和Level 3。最后,MV的起始条件和操作约束为:

|步骤 |部分 |变量 |属性 |新值|

| ------------- |:-------------:| -----:|

|1| MV |All MVs |Control Status(控制状态)| Remote|

|1| MV| All MVs| Maximum(最大值) |100.00|

|1| MV |All MVs| Maximum Move Size(最大动作幅度)| 10.00|

|1| MV |All MVs| Minimum(最小值)| 0.00|

|1| MV| All MVs |Operating Point(操作点)| 50.00|

原文:

Case 4: Level Control for Three Tanks in Series

The application under consideration in this example is an extension of the case seen in the previous case study. Consider a process containing three equally-sized vessels in series. The control objective is to maintain the three vessel levels (CVs) of interest at prescribed user-specified set points. To that end, three flow rates valve OPs (MVs) are available for manipulation. The inlet flow rate into the first vessel is a measured disturbance not available for manipulation (DV). The figure below shows the process schematic.

**Process Model **

The figure below shows the process model used for the system. Note the colored blocks in the model as the simulation plots will have the same color coding, purple for DV, red for CV1, green for CV2 and lastly blue for CV3. The control model is compiled with a Control Period of 1.0 minute.

Controller Design

The controller application under consideration has all the levels defined as CVs in a single sub-controller.

We specify unity weights for all the MVs as well as CVs:

Lastly, as in the previous single vessel example we modify the MV horizon for this controller from its default value of 100 × dT to 5 × dT as seen below. Again, remember to use the Calculator feature so that the CV prediction horizon gets automatically adjusted accordingly.

The controller has neither economic functions nor static constraints.

**Simulation **

In this example we consider a series of experiments to establish the importance of correctly specifying the CV priorities in the presence of multiple competing ramp CVs. Performing this specification properly is especially important when the controller runs in crippled mode.

All of the simulation runs to be presented in this example have the starting conditions specified below. The POV starting conditions are:

|Step| Section| Variable |Attribute| New Value|

| ------------- |:-------------:| -----:|

|1 |POV |All CVs| Impulse factor| 0.9|

|1 |POV |All CVs |Operating Point| 50.00|

Essentially we start all the level CVs at 50 and they all have a high Impulse Factor. Next, the CV starting conditions are:

|Step |Section |Variable |Attribute| New Value|

| ------------- |:-------------:| -----:|

|1 |CV| CV_1 |Setrange High |60.00|

|1 |CV| CV_1 |Setrange Low |60.00|

|1| CV| CV_2 |Setrange High |60.00|

|1| CV| CV_2| Setrange Low| 50.00|

|1| CV| CV_3| Setrange High| 40.00|

|1| CV |CV_4| Setrange Low| 40.00|

The desired setpoints for the levels are 60, 50 and 40 respectively for Level 1, Level 2 and Level 3. Lastly, the MV starting conditions as well as operating constraints are:

|Step| Section |Variable| Attribute |New Value|

| ------------- |:-------------:| -----:|

|1| MV| All MVs |Control Status| Remote|

|1| MV| All MVs| Maximum |100.00|

|1| MV| All MVs| Maximum Move Size |10.00|

|1| MV| All MVs| Minimum| 0.00|

|1| MV| All MVs| Operating Point| 50.00|

2016.5.26