FPGA基础入门【15】开发板I2C温度传感器配置

上一篇教程挖了一个NEXYS4 开发板中MicroSD的天坑,发现难度过高,打算放到之后再完成,这一篇来电不这么重口味的温度传感器配置。在NEXYS 4开发板上的温度传感器使用的是I2C接口,这个接口很常见,可以写一个模块留着以后使用

FPGA基础入门【15】开发板I2C温度传感器配置

- 开发板温度传感器

- I2C接口简介

- ADT7420简介

- 寄存器

- 逻辑设计

- I2C控制模块

- UART串口控制模块

- 顶层逻辑

- 模拟仿真

- Testbench

- 仿真脚本

- 仿真结果

- 编译测试

- 结果

- 总结

开发板温度传感器

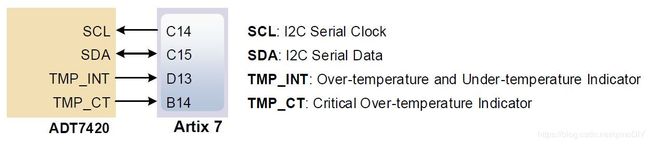

NEXYS 4文档中写着它使用的温度传感器名字是Analog Device ADT7420,提供16位精度,一般精确到0.25摄氏度,用I2C接口和FPGA连接如下:

SCL和SDA是I2C接口,用来和FPGA连接。可以看到它只有两根线,非常精简,一般用来和不太复杂的外围设备连接。并且它还有地址识别,因此1个master设备可以同时和多个slave设备相连。剩下两条线表示温度溢出(过高或者过低),以及温度高到有危险的程度。

ADT7420的文档链接:ADT7420

I2C接口简介

从ADT7420的文档中读到,它的时钟需求是400kHz以下,我们采用200kHz,需要把系统时钟100MHz减慢500倍

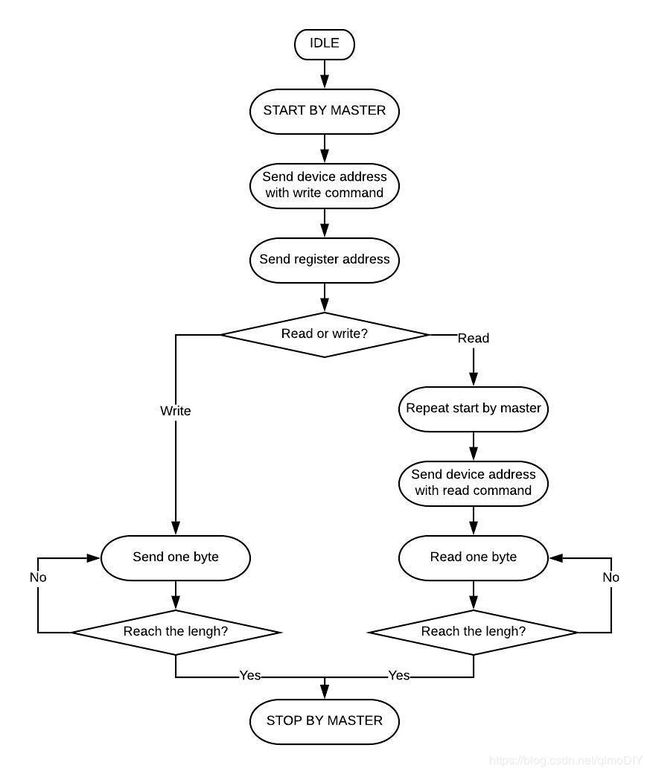

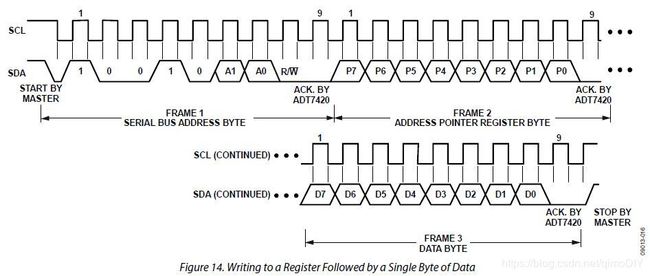

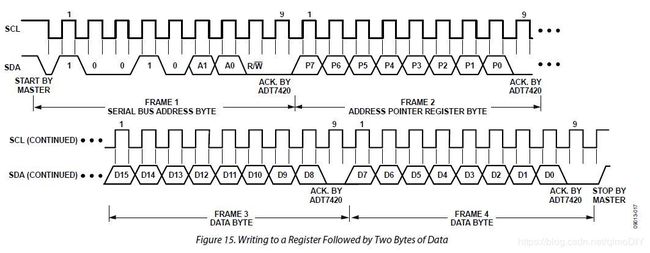

和这款芯片相关的I2C的时序如下:

写单字节数据

写双字节数据:

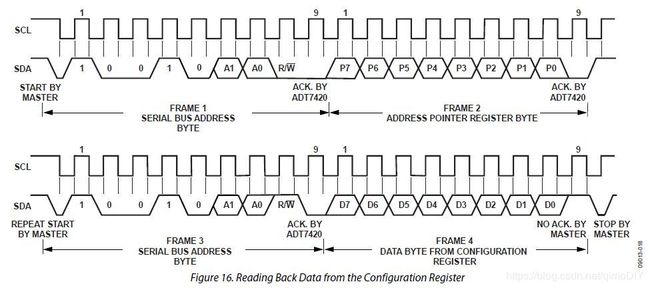

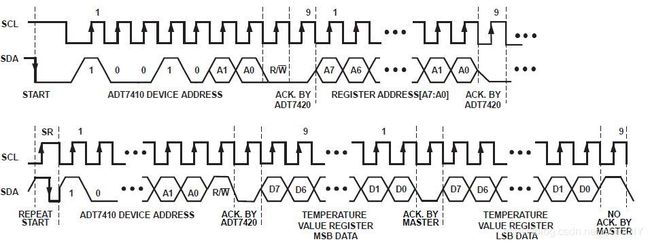

从配置寄存器中读取数据:

读取温度数据:

- 在SCL为高电平时,拉低SDA是开始信号

- 在SCL为高电平时,拉高SDA是结束信号

- Master设备在读回信号的最后传出低电平表示,再来一个,高电平表示,够了够了不用再传了

从这个时序图看出,I2C读写控制参数有四个:读写控制、寄存器地址、读写数据长度、写的8位数据(每完成一次输出就更新一次)

ADT7420简介

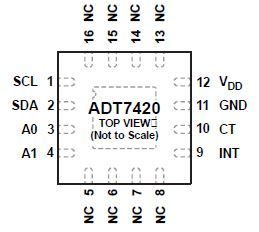

网上很多Arduino用的温度传感器模块用的就是这款芯片,引脚如下:

其中SCL和SDA是和FPGA相连的I2C接口,CT和INT是临界温度警告,VDD和GND是电源和接地,A0和A1是低地址位,在芯片较少时可以直接通过连线来同时连接几个芯片。

NEXYS 4文档中说要制定slave地址0x4B来和传感器通信,通过前面的I2C接口介绍可以看出,开发板把A0和A1两个引脚都拉高了。

ADT7420在上电后会自动进入简单温度传感器模式,不需要初始化配置。设备地址寄存器一开始被指向温度数据的高位MSB,因此不用制定地址读出来的第一个字节就是温度的MSB,第二个字节是LSB,组成需要的16位结果。因此上面的时序图中读取温度的两步,如果一开始没有做别的操作,可以把写地址省略。把16位结果右移3位,再除以16,就可以得到摄氏温度

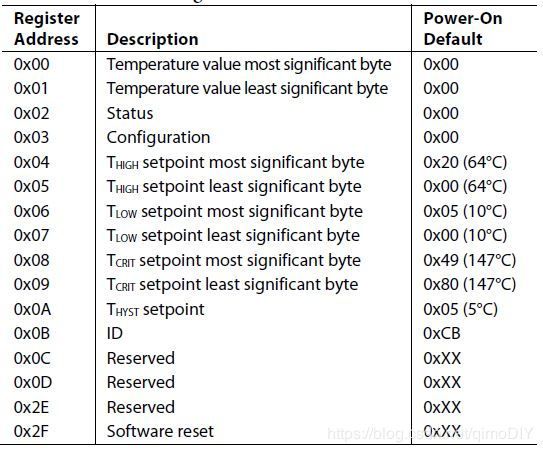

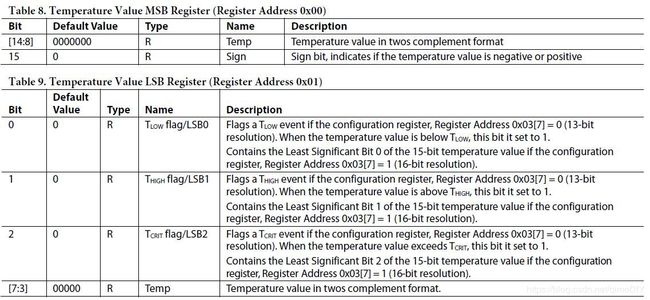

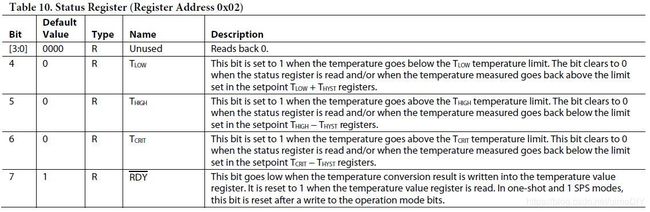

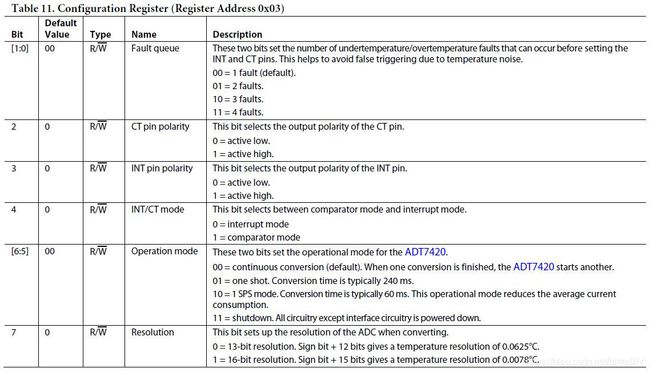

寄存器

ADT7420的寄存器全家福及其默认值如下:

这里我们只关注温度高低位、状态和配置四个寄存器

温度高低位:

状态寄存器,复位后要先等这个寄存器的最高位变成0:

配置寄存器:

逻辑设计

首先需要一个I2C的控制逻辑模块I2C_transmitter.v,然后就可以配置一个串口控制器,随时读取寄存器与数据。这里我们把之前做过的串口模块集成一下,加个FIFO以便之后再使用

这次的代码比较长,要把之前做过的一些东西做个综合

I2C控制模块

从前面的I2C时序逻辑可以分析,定义一段I2C数据传输参数有这么几个:寄存器地址、读写选择、读写长度、需要写入的8位数据。

新建一个代码文件I2C_transmitter.v,代码如下:

顶层接口配置,前面分析过I2C必要参数,还需要一些其他的控制信号

- 设备地址dev_addr,这个应该连到固定值0x4B

- 读写控制rdh_wrl,高电平代表读,低电平代表写

- 寄存器地址reg_addr

- 操作准备信号ready,它的上升沿代表数据准备完成,可以进行I2C传输

- 输出8位数据dout

- 传输长度dout_length

- 输出确认dout_ack,表示一个byte已经输出完成,可以更新到下一个byte

- 输入8位数据din

- 输入准备信号din_valid,每当此信号升高,就有一个byte输入在din接口准备好

module I2C_transmitter(

input clk,

input rst,

output reg I2C_SCL,

output reg I2C_SDA_out,

input I2C_SDA_in,

output reg I2C_SDA_oe,

input [6:0] dev_addr, // device address

input [7:0] reg_addr, // register address

input rdh_wrl, // 1 is read, 0 is write

input ready, // write and read ready

input [7:0] dout, // write data

output reg dout_ack, // write data acknowledge by slave device

input [3:0] dout_length, // the number of bytes of write and read data

output reg [7:0] din,

output reg din_valid

);

生成I2C接口需要的100kHz时钟,用I2C_SCL_en来使能控制

// SCL clock generator, 100MHz => 200kHz

reg [7:0] I2C_SCL_counter;

reg I2C_SCL_en; // enable signal, SCL only driven when this one asserted

reg I2C_SCL_d;

wire I2C_SCL_posedge;

wire I2C_SCL_negedge;

always @(posedge clk) begin

if(rst | ~(I2C_SCL_en)) begin

I2C_SCL_counter <= 8'd0;

I2C_SCL <= 1'b1;

end

else if(I2C_SCL_counter < 8'd250) begin

I2C_SCL_counter <= I2C_SCL_counter + 8'd1;

end

else begin

I2C_SCL_counter <= 8'd0;

I2C_SCL <= ~I2C_SCL;

end

end

实时监测SCL的上升沿和下降沿,由于SDA是双向的信号,读的时候用上升沿,写的时候用下降沿,经常需要切换

// detection of falling edge of SCL

always @(posedge clk) begin

I2C_SCL_d <= I2C_SCL;

end

assign I2C_SCL_negedge = ({I2C_SCL_d,I2C_SCL}==2'b10) ? 1'b1 : 1'b0;

assign I2C_SCL_posedge = ({I2C_SCL_d,I2C_SCL}==2'b01) ? 1'b1 : 1'b0;

探测ready信号的上升沿以开始I2C传输

// ready rising edge detection

reg ready_d;

wire ready_posedge;

always @(posedge clk) begin

ready_d <= ready;

end

assign ready_posedge = ({ready_d, ready}==2'b01) ? 1'b1 : 1'b0;

状态机配置

// state machine

parameter [3:0] IDLE = 0;

parameter [3:0] WAIT = 1;

parameter [3:0] ADDR_DEV_WRITE = 2;

parameter [3:0] ADDR_REG = 3;

parameter [3:0] REPEAT_START = 4;

parameter [3:0] ADDR_DEV_READ = 5;

parameter [3:0] WRITE = 6;

parameter [3:0] READ = 7;

parameter [3:0] ENDING = 8;

reg [3:0] state;

reg [3:0] next_state;

reg [3:0] I2C_SCL_count;

reg [7:0] dout_buf;

reg [3:0] dout_count;

reg [7:0] din_buf;

reg [7:0] end_count;

always @(posedge clk or posedge rst) begin

if(rst) begin

state <= IDLE;

end

else begin

state <= next_state;

end

end

always @(posedge clk) begin

case(state)

IDLE: begin

dout_ack <= 1'b0;

I2C_SCL_count <= 4'd0;

din <= 8'h00;

din_valid <= 1'b0;

I2C_SDA_out <= 1'b1;

I2C_SDA_oe <= 1'b1;

next_state <= WAIT;

dout_buf <= 8'h00;

I2C_SCL_en <= 1'b0;

dout_count <= 4'd0;

end_count <= 8'd0;

end

侦测到ready上升沿,在SCL为高的情况下拉低SDA表示开始(Start by master),这也就是SCL生成器在复位情况下为高的原因

WAIT: begin

if(ready_posedge) begin

next_state <= ADDR_DEV_WRITE;

dout_buf <= {dev_addr, 1'b0}; // the first step is always write register address

I2C_SDA_out <= 1'b0;

I2C_SDA_oe <= 1'b1;

I2C_SCL_en <= 1'b1;

end

end

输出设备地址0x4B,带上最低位为1表示写入,经历9个时钟周期,最后一个上升沿观察设备是否传回一个ack信号

ADDR_DEV_WRITE: begin

if(I2C_SCL_negedge && (I2C_SCL_count < 4'd8) ) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

{I2C_SDA_out, dout_buf} <= {dout_buf, 1'b0};

I2C_SDA_oe <= 1'b1;

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd8)) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

I2C_SDA_oe <= 1'b0;

end

else if(I2C_SCL_posedge && (I2C_SCL_count == 4'd9)) begin

I2C_SCL_count <= 4'd0;

dout_buf <= reg_addr;

if(~I2C_SDA_in) begin // acknowledged by device and turn to ADDR_REG state

next_state <= ADDR_REG;

end

else begin // not acknowledged, go to ENDING

next_state <= ENDING;

end

end

end

写入寄存器地址,根据读写控制信号进入读流程或者写流程

ADDR_REG: begin

if(I2C_SCL_negedge && (I2C_SCL_count < 4'd8) ) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

{I2C_SDA_out, dout_buf} <= {dout_buf, 1'b0};

I2C_SDA_oe <= 1'b1;

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd8)) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

I2C_SDA_oe <= 1'b0;

end

else if(I2C_SCL_posedge && (I2C_SCL_count == 4'd9)) begin

I2C_SCL_count <= 4'd0;

if(rdh_wrl && ~I2C_SDA_in) begin // acknowledged by device and turn to read state

next_state <= REPEAT_START;

dout_buf <= {dev_addr, 1'b1};

end

else if(~rdh_wrl && ~I2C_SDA_in) begin // acknowledged by device and turn to write state

next_state <= WRITE;

dout_buf <= dout;

end

else begin // not acknowledged, go to ENDING

next_state <= ENDING;

end

end

end

当需要读数据时,需要再次进行Start by master,拉高SDA后,在SCL的高电平时拉低SDA

REPEAT_START: begin

// not stopped by master

if(I2C_SCL_negedge) begin

I2C_SDA_oe <= 1'b1;

I2C_SDA_out <= 1'b1;

end

else if(I2C_SCL_posedge) begin

I2C_SCL_en <= 1'b0;

end

// delay a while and pull down the SDA, indicating repeat start

else if(~I2C_SCL_en && (end_count < 8'd250)) begin

end_count <= end_count + 8'd1;

end

else if(~I2C_SCL_en) begin

end_count <= 8'd0;

I2C_SDA_out <= 1'b0;

I2C_SCL_en <= 1'b1;

next_state <= ADDR_DEV_READ;

end

end

读流程还需要再写一次设备地址,并把最后一位改成高电平以表示读取

ADDR_DEV_READ: begin

if(I2C_SCL_negedge && (I2C_SCL_count < 4'd8) ) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

{I2C_SDA_out, dout_buf} <= {dout_buf, 1'b0};

I2C_SDA_oe <= 1'b1;

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd8)) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

I2C_SDA_oe <= 1'b0;

end

else if(I2C_SCL_posedge && (I2C_SCL_count == 4'd9)) begin

I2C_SCL_count <= 4'd0;

if(~I2C_SDA_in) begin // acknowledged by device and turn to read state

next_state <= READ;

end

else begin // not acknowledged, go to ENDING

next_state <= ENDING;

end

end

end

写操作,将一个byte输出给设备,获得ack信号后计算是否已经输出到指定长度,如果已经达到则进入结束流程

WRITE: begin

if(I2C_SCL_negedge && (I2C_SCL_count < 4'd8) ) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

{I2C_SDA_out, dout_buf} <= {dout_buf, 1'b0};

dout_ack <= 1'b0;

I2C_SDA_oe <= 1'b1;

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd8)) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

dout_ack <= 1'b1; // indicate that ready to take next output data

I2C_SDA_oe <= 1'b0;

end

else if(I2C_SCL_posedge && (I2C_SCL_count == 4'd9)) begin

dout_buf <= dout;

I2C_SCL_count <= 4'd0;

if(~I2C_SDA_in && (dout_count == (dout_length - 4'd1)) ) begin // acknowledged by device, write enough, go to ENDING

next_state <= ENDING;

dout_count <= 4'd0;

end

else if(~I2C_SDA_in) begin // acknowledged by device, not write enough, keep in WRITE

next_state <= WRITE;

dout_count <= dout_count + 4'd1;

end

else begin // not acknowledged by device, go to ENDING

next_state <= ENDING;

dout_count <= 4'd0;

end

end

else begin

dout_ack <= 1'b0;

end

end

读操作,从设备读取一个byte后,如果还没有读取足够数据,则在第九个时钟周期输出一个低电平作为ack信号,否则输出一个高电平作为no ack信号,表示master已经读取了足够的数据

READ: begin

if(I2C_SCL_posedge && (I2C_SCL_count < 4'd8) ) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

din_buf <= {din_buf[6:0], I2C_SDA_in};

din_valid <= 1'b0;

I2C_SDA_oe <= 1'b0;

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd8)) begin

I2C_SCL_count <= I2C_SCL_count + 4'd1;

din <= din_buf;

din_valid <= 1'b1;

I2C_SDA_oe <= 1'b1;

if(dout_count == (dout_length - 4'd1) ) begin // already read enough, send no ack

I2C_SDA_out <= 1'b1;

end

else begin // need more data, send ack to device

I2C_SDA_out <= 1'b0;

end

end

else if(I2C_SCL_negedge && (I2C_SCL_count == 4'd9)) begin

I2C_SCL_count <= 4'd0;

I2C_SDA_oe <= 1'b0;

if(dout_count == (dout_length - 4'd1) ) begin // already read enough, go to ENDING

next_state <= ENDING;

dout_count <= 4'd0;

end

else begin // need more data, continue in READ state

next_state <= READ;

dout_count <= dout_count + 4'd1;

end

end

else begin

din_valid <= 1'b0;

end

end

结尾操作,关闭SCL生成器,在SCL的高电平拉高SDA(Stop by master)

ENDING: begin

if(I2C_SCL_posedge) begin

I2C_SCL_en <= 1'b0;

I2C_SDA_oe <= 1'b1;

I2C_SDA_out <= 1'b0;

end

// delay a while and pull up the SDA, indicating the end

if(~I2C_SCL_en && (end_count < 8'd250)) begin

end_count <= end_count + 8'd1;

end

else if(~I2C_SCL_en) begin

I2C_SDA_out <= 1'b1;

next_state <= IDLE;

end

end

endcase

end

endmodule

UART串口控制模块

看过前面教程的人可能会觉得奇怪,为什么还需要写UART串口控制的模块,明明已经有它的逻辑代码了。问题是ADT7420的I2C接口(包括不少其他芯片的I2C)使用的时钟是400kHz以下,一般比UART串口用的波特率115200要高很多,如果继续用之前的简单逻辑会出现串口数据还没送完,新的数据就已经进来的情况。

这里我们改进一下串口逻辑,添加一个同步先入先出队列(First in first out, FIFO)。FIFO在FPGA设计中非常常见,通过调用少量存储器平衡写入和读出两端的速度差。同步是指读写用的是同一个时钟,读写使能可以在不同的时间段激活,对于高速时钟控制低速接口很有用。异步FIFO是用在读写用的是不同时钟的情况下(不是读写使能信号),比起同步FIFO,它的难点在于跨越了时钟域,这部分有很多细节,以后再写。

同步FIFO的代码syn_fifo.v如下:

顶层接口定义,这里我们用了模块定义参数,在名称后面加上井号#与一对括号,在其中定义一些与该模块有关的参数,比如FIFO的数据宽度和地址长度,这样在调用相似模块时不用写多个模块,只需要在调用时候配置不同参数即可

接口比较简单,rd_en读使能的高电平时读取一个FIFO数据到data_out,wr_en写使能的高电平时写一个data_in到FIFO中,empty和full分表代表FIFO空了或者满了,避免出现错误

module syn_fifo #

(

// FIFO constants

parameter DATA_WIDTH = 8,

parameter ADDR_WIDTH = 8

)

(

input clk , // Clock input

input rst , // Active high reset

input [DATA_WIDTH-1:0] data_in , // Data input

input rd_en , // Read enable

input wr_en , // Write Enable

output reg [DATA_WIDTH-1:0] data_out , // Data Output

output empty , // FIFO empty

output full // FIFO full

);

最大深度由地址宽度决定,定义RAM的读指针和写指针(可循环),加上一个FIFO有效计数器,用来观察FIFO是空还是满。

这里data_ram是RAM的核心,定义比较特殊,前面的宽度代表每个地址对应的数据宽度,后面的是定义它的深度

// RAM definition

parameter RAM_DEPTH = (1 << ADDR_WIDTH);

reg [DATA_WIDTH-1:0] data_ram[ADDR_WIDTH-1:0];

// Pointers and counters

reg [ADDR_WIDTH-1:0] wr_pointer;

reg [ADDR_WIDTH-1:0] rd_pointer;

reg [ADDR_WIDTH :0] status_cnt;

assign full = (status_cnt == (RAM_DEPTH-1));

assign empty = (status_cnt == 0);

// WRITE_POINTER

always @(posedge clk or posedge rst) begin

if(rst) begin

wr_pointer <= 0;

end else if(wr_en) begin

wr_pointer <= wr_pointer + 1;

end

end

// READ_POINTER

always @(posedge clk or posedge rst) begin

if(rst) begin

rd_pointer <= 0;

end

else if(rd_en) begin

rd_pointer <= rd_pointer + 1;

end

end

定义一个RAM,通过操控读写的地址来读写数据

// READ DATA

always @(posedge clk or posedge rst) begin

if(rst) begin

data_out <= 0;

end

else if(rd_en) begin

data_out <= data_ram[rd_pointer];

end

end

// WRITE DATA

always @(posedge clk) begin

if(wr_en) begin

data_ram[wr_pointer] <= data_in;

end

end

// STATUS COUNTER

always @(posedge clk or posedge rst) begin

if(rst) begin

status_cnt <= 0;

// Read but no write.

end

else if(rd_en && !wr_en && (status_cnt != 0)) begin

status_cnt <= status_cnt - 1;

// Write but no read.

end

else if(wr_en && !rd_en && (status_cnt != RAM_DEPTH)) begin

status_cnt <= status_cnt + 1;

end

end

endmodule

有了FIFO的代码,我们可以改进之前的串口控制代码为UART_transmitter.v:

顶层定义,除了UART必要的接口外,加上dout、din以及他们的准备信号。这些信号都是十六进制数,每4位都是一位数

module UART_transmitter(

input clk,

input rst,

// UART port

output reg TXD,

input RXD,

output reg CTS,

input RTS,

// Control port

input [7:0] dout,

input dout_ready,

output reg [3:0] din,

output reg din_valid

);

加入前面写好的FIFO代码,调用时参数的配置可以参考下面的代码

// FIFO definition

wire [7:0] fifo_data_in;

wire [7:0] fifo_data_out;

reg fifo_rd_en;

reg fifo_rd_en_d1;

reg fifo_rd_en_d2;

wire fifo_wr_en;

wire fifo_empty;

wire fifo_full;

assign fifo_data_in = dout;

assign fifo_wr_en = dout_ready;

syn_fifo #

(

// FIFO constants

.DATA_WIDTH(8),

.ADDR_WIDTH(4)

) syn_fifo

(

.clk (clk), // Clock input

.rst (rst), // Active high reset

.data_in (fifo_data_in), // Data input

.rd_en (fifo_rd_en), // Read enable

.wr_en (fifo_wr_en), // Write Enable

.data_out (fifo_data_out), // Data Output

.empty (fifo_empty), // FIFO empty

.full (fifo_full) // FIFO full

);

和之前差不多的串口发送端代码,去除了接收回传,这部分由调用串口模块的顶层做

// resource definition

reg [15:0] tx_count;

reg [19:0] tx_shift;

reg tx_start;

reg [19:0] CTS_delay;

reg [7:0] RXD_delay;

reg [15:0] rx_count;

reg [3:0] rx_bit_count;

reg rx_start;

always @(posedge clk) begin

fifo_rd_en_d1 <= fifo_rd_en;

fifo_rd_en_d2 <= fifo_rd_en_d1;

end

always @(posedge clk or posedge rst) begin

if(rst) begin

tx_count <= 16'd0;

TXD <= 1'b1;

tx_shift <= 20'hFFFFF;

CTS <= 1'b1;

CTS_delay <= 20'hFFFFF;

fifo_rd_en <= 1'b0;

tx_start <= 1'b0;

end

// When FIFO is not empty, and last sending completed, read the next data, and send through UART

else if(~tx_start && ~fifo_empty) begin

fifo_rd_en <= 1'b1;

tx_start <= 1'b1;

end

// FIFO ready complete, get the data, transfer and buffer it into register

else if(fifo_rd_en_d2) begin

fifo_rd_en <= 1'b0;

case(fifo_data_out[3:0])

4'h0: begin tx_shift[9:0] <= 10'b0000011001; end

4'h1: begin tx_shift[9:0] <= 10'b0100011001; end

4'h2: begin tx_shift[9:0] <= 10'b0010011001; end

4'h3: begin tx_shift[9:0] <= 10'b0110011001; end

4'h4: begin tx_shift[9:0] <= 10'b0001011001; end

4'h5: begin tx_shift[9:0] <= 10'b0101011001; end

4'h6: begin tx_shift[9:0] <= 10'b0011011001; end

4'h7: begin tx_shift[9:0] <= 10'b0111011001; end

4'h8: begin tx_shift[9:0] <= 10'b0000111001; end

4'h9: begin tx_shift[9:0] <= 10'b0100111001; end

4'hA: begin tx_shift[9:0] <= 10'b0100000101; end

4'hB: begin tx_shift[9:0] <= 10'b0010000101; end

4'hC: begin tx_shift[9:0] <= 10'b0110000101; end

4'hD: begin tx_shift[9:0] <= 10'b0001000101; end

4'hE: begin tx_shift[9:0] <= 10'b0101000101; end

4'hF: begin tx_shift[9:0] <= 10'b0011000101; end

endcase

case(fifo_data_out[7:4])

4'h0: begin tx_shift[19:10] <= 10'b0000011001; end

4'h1: begin tx_shift[19:10] <= 10'b0100011001; end

4'h2: begin tx_shift[19:10] <= 10'b0010011001; end

4'h3: begin tx_shift[19:10] <= 10'b0110011001; end

4'h4: begin tx_shift[19:10] <= 10'b0001011001; end

4'h5: begin tx_shift[19:10] <= 10'b0101011001; end

4'h6: begin tx_shift[19:10] <= 10'b0011011001; end

4'h7: begin tx_shift[19:10] <= 10'b0111011001; end

4'h8: begin tx_shift[19:10] <= 10'b0000111001; end

4'h9: begin tx_shift[19:10] <= 10'b0100111001; end

4'hA: begin tx_shift[19:10] <= 10'b0100000101; end

4'hB: begin tx_shift[19:10] <= 10'b0010000101; end

4'hC: begin tx_shift[19:10] <= 10'b0110000101; end

4'hD: begin tx_shift[19:10] <= 10'b0001000101; end

4'hE: begin tx_shift[19:10] <= 10'b0101000101; end

4'hF: begin tx_shift[19:10] <= 10'b0011000101; end

endcase

CTS_delay <= 20'h00000;

end

// Shift out the received data

else begin

fifo_rd_en <= 1'b0;

if(tx_count < 16'd867) begin

tx_count <= tx_count + 16'd1;

end

else begin

tx_count <= 16'd0;

end

if(tx_count == 16'd0) begin

TXD <= tx_shift[19];

tx_shift <= {tx_shift[18:0], 1'b1};

CTS <= CTS_delay[19];

CTS_delay <= {CTS_delay[18:0], 1'b1};

tx_start <= ~CTS_delay[19];

end

end

end

和之前差不多的串口接收逻辑,加入了转换成16进制数的逻辑,每次输出一个4位的十六进制数

// Input from uart

always @(posedge clk or posedge rst) begin

if(rst) begin

RXD_delay <= 8'h00;

rx_count <= 16'd0;

rx_bit_count <= 4'd0;

din_valid <= 1'b0;

rx_start <= 1'b0;

end

else if(~RTS) begin

if(rx_count < 16'd867) begin

rx_count <= rx_count + 16'd1;

end

else begin

rx_count <= 16'd0;

end

if( (rx_count == 16'd0) && (~RXD) && (~rx_start) ) begin

RXD_delay <= 8'h00;

rx_bit_count <= 4'd0;

rx_start <= 1'b1;

end

else if( (rx_count == 16'd0) && rx_start && (rx_bit_count != 4'd8)) begin

rx_bit_count <= rx_bit_count + 4'd1;

RXD_delay <= {RXD_delay[6:0], RXD};

end

else if( (rx_count == 16'd0) && rx_start) begin

rx_start <= 1'b0;

rx_bit_count <= 4'd0;

din_valid <= 1'b1;

// Need to transfer the received data into hex data

case(RXD_delay[7:0])

8'b00001100 : begin din <= 4'h0; end

8'b10001100 : begin din <= 4'h1; end

8'b01001100 : begin din <= 4'h2; end

8'b11001100 : begin din <= 4'h3; end

8'b00101100 : begin din <= 4'h4; end

8'b10101100 : begin din <= 4'h5; end

8'b01101100 : begin din <= 4'h6; end

8'b11101100 : begin din <= 4'h7; end

8'b00011100 : begin din <= 4'h8; end

8'b10011100 : begin din <= 4'h9; end

8'b10000010 : begin din <= 4'hA; end

8'b01000010 : begin din <= 4'hB; end

8'b11000010 : begin din <= 4'hC; end

8'b00100010 : begin din <= 4'hD; end

8'b10100010 : begin din <= 4'hE; end

8'b01100010 : begin din <= 4'hF; end

endcase

end

else begin

din_valid <= 1'b0;

end

end

end

endmodule

顶层逻辑

做好两个接口的准备工作,开始写顶层的temperature.v:

顶层定义,时钟复位和LED,I2C接口以及UART串口接口

module temperature(

input clk,

input rst,

output reg [1:0] led,

// I2C port

output SCL,

inout SDA,

input TMP_INT,

input TMP_CT,

// UART port

input RXD,

output TXD,

output CTS,

input RTS

);

将ADT7420另外两个引脚直接连接到LED上

// LED on when the temperature over limit

always @(posedge clk or posedge rst) begin

if(rst) begin

led <= 2'b00;

end

else begin

led <= {TMP_CT, TMP_INT};

end

end

// output control of pin SDA

wire SDA_in, SDA_out, SDA_oe;

assign SDA = (SDA_oe) ? SDA_out : 1'bz;

assign SDA_in = SDA;

// I2C interface controller

reg [7:0] I2C_reg_addr;

reg I2C_rdh_wrl;

reg I2C_ready;

reg [7:0] I2C_dout;

wire I2C_dout_ack;

reg [3:0] I2C_dout_length;

wire [7:0] I2C_din;

wire I2C_din_valid;

调用前面写好的I2C控制器

I2C_transmitter I2C_transmitter(

.clk (clk),

.rst (rst),

.I2C_SCL (SCL),

.I2C_SDA_out (SDA_out),

.I2C_SDA_in (SDA_in),

.I2C_SDA_oe (SDA_oe),

.dev_addr (7'h4B), // device address

.reg_addr (I2C_reg_addr), // register address

.rdh_wrl (I2C_rdh_wrl), // 1 is read, 0 is write

.ready (I2C_ready), // write and read ready

.dout (I2C_dout), // write data

.dout_ack (I2C_dout_ack), // write data acknowledge by slave device

.dout_length (I2C_dout_length), // the number of bytes of write and read data

.din (I2C_din),

.din_valid (I2C_din_valid)

);

调用前面写好的UART串口控制模块

// Data IO with UART

wire [3:0] uart_din;

wire uart_din_valid;

reg [7:0] uart_dout;

reg uart_dout_ready;

UART_transmitter UART_transmitter(

.clk (clk),

.rst (rst),

// UART port

.TXD (TXD),

.RXD (RXD),

.CTS (CTS),

.RTS (RTS),

// Control port

.dout (uart_dout),

.dout_ready (uart_dout_ready),

.din (uart_din),

.din_valid (uart_din_valid)

);

根据串口接收到的指令,进行不同的读写操作

- 0读取温度数据,传回四个byte

- 1读取ADT7420的状态寄存器,期望是0x00

- 2读取温度上限高位寄存器

- 3把温度上限设置为28摄氏度

- 4把温度上限改回默认的64摄氏度

另外把串口接收到的数据重传回PC,用来显示自己打入的命令,由于收到的是4位,而输出是8位,在高位加4位0

// Interface between UART and I2C

always @(posedge clk or posedge rst) begin

if(rst) begin

uart_dout <= 8'h00;

uart_dout_ready <= 1'b0;

end

else if(uart_din_valid) begin

// return it back to UART, to show up in console

uart_dout <= {4'h0,uart_din};

uart_dout_ready <= 1'b1;

// send command to I2C according to the number

I2C_ready <= 1'b1;

case(uart_din)

4'h0: begin

I2C_dout <= 8'h00; I2C_reg_addr <= 8'h00; I2C_rdh_wrl <= 1'b1; I2C_dout_length <= 4'd2;

end // Read two bytes from device

4'h1: begin

I2C_dout <= 8'h00; I2C_reg_addr <= 8'h02; I2C_rdh_wrl <= 1'b1; I2C_dout_length <= 4'd1;

end // Read Status

4'h2: begin

I2C_dout <= 8'h00; I2C_reg_addr <= 8'h04; I2C_rdh_wrl <= 1'b1; I2C_dout_length <= 4'd1;

end // Read back from T_high MSB

4'h3: begin

I2C_dout <= 8'h0E; I2C_reg_addr <= 8'h04; I2C_rdh_wrl <= 1'b0; I2C_dout_length <= 4'd1;

end // Set T_high to 28 Celsius

4'h4: begin

I2C_dout <= 8'h20; I2C_reg_addr <= 8'h04; I2C_rdh_wrl <= 1'b0; I2C_dout_length <= 4'd1;

end // Set T_high to 64 Celsius again

default: begin

I2C_dout <= 8'h00; I2C_reg_addr <= 8'h00; I2C_rdh_wrl <= 1'b1; I2C_dout_length <= 4'd2;

end

endcase

end

else if(I2C_din_valid) begin

// receive data from I2C and transfer it to UART

uart_dout <= I2C_din;

uart_dout_ready <= 1'b1;

end

else begin

// in case some signal is two clock cycles wide

uart_dout_ready <= 1'b0;

I2C_ready <= 1'b0;

end

end

endmodule

模拟仿真

和之前一样,要写一个Testbench和一个仿真脚本来仿真

Testbench

代码tb_temperature如下:

`timescale 1ns/1ns

module tb_temperature;

reg clock;

reg reset;

wire SCL;

wire SDA;

reg SDA_oe;

reg SDA_in;

wire SDA_out;

wire TMP_INT;

wire TMP_CT;

assign SDA = (SDA_oe) ? 1'bz : SDA_in;

assign SDA_out = SDA;

reg RXD;

wire TXD;

wire CTS;

reg RTS;

reg [9:0] RXD_buf;

reg [7:0] SDA_out_buf;

复位以后,参考I2C的时序,接收或者传回生成的数据,使用指令0,读取温度数据

initial begin

clock = 1'b0;

reset = 1'b0;

RXD = 1'b1;

RTS = 1'b1;

SDA_oe = 1'b1;

SDA_in = 1'b0;

SDA_out_buf = 8'h00;

// Reset for 1us

#100

reset = 1'b1;

#1000

reset = 1'b0;

// Send a number 0 into uart

RXD_buf = 10'b0000011001;

RTS = 1'b0;

repeat(10) begin

repeat(867) @(posedge clock);

{RXD, RXD_buf} = {RXD_buf, 1'b1};

end

// Send signal to I2C port to read

@(negedge SCL)

SDA_oe = 1'b1;

repeat(8) begin

@(posedge SCL) SDA_out_buf = {SDA_out_buf[6:0], SDA_out};

end

// Ack from device to FPGA

@(posedge SCL)

SDA_oe = 1'b0;

SDA_in = 1'b0;

@(negedge SCL)

SDA_oe = 1'b1;

repeat(8) begin

@(posedge SCL) SDA_out_buf = {SDA_out_buf[6:0], SDA_out};

end

// Ack from device to FPGA

@(posedge SCL)

SDA_oe = 1'b0;

SDA_in = 1'b0;

@(posedge SCL); // waiting for the repeat start

@(negedge SCL)

SDA_oe = 1'b1;

repeat(8) begin

@(posedge SCL) SDA_out_buf = {SDA_out_buf[6:0], SDA_out};

end

// Ack from device to FPGA

@(posedge SCL)

SDA_oe = 1'b0;

SDA_in = 1'b0;

repeat(8) begin

@(posedge SCL) SDA_in <= ~SDA_in;

end

// Ack from FPGA to device

@(negedge SCL)

SDA_oe = 1'b1;

@(posedge SCL)

SDA_oe = 1'b0;

SDA_in = 1'b0;

repeat(8) begin

@(posedge SCL) SDA_in <= ~SDA_in;

end

// Ack from FPGA to device

@(negedge SCL)

SDA_oe = 1'b1;

end

// Generate 100MHz clock signal

always #5 clock <= ~clock;

temperature temperature(

.clk (clock),

.rst (reset),

// I2C port

.SCL (SCL),

.SDA (SDA),

.TMP_INT (TMP_INT),

.TMP_CT (TMP_CT),

// UART port

.RXD (RXD),

.TXD (TXD),

.CTS (TXD),

.RTS (RTS)

);

endmodule

仿真脚本

写脚本sim.do如下:

vlib work

vlog ../src/temperature.v ../src/I2C_transmitter.v ../src/UART_transmitter.v ../src/syn_fifo.v ./tb_temperature.v

vsim work.tb_temperature -voptargs=+acc +notimingchecks

log -depth 7 /tb_temperature/*

#do wave.do

run 1ms

调用前面全部的代码,打开ModelSim后转到脚本在的路径,使用命令do sim.do即可开始仿真。

仿真时可以添加想要的信号到waveform窗口中观察,然后可以保存为wave.do,这样下次可以通过调用它来加入一样的信号,节省一个一个加入的时间,这时你可以把sim.do中被#注释掉的那行去注释

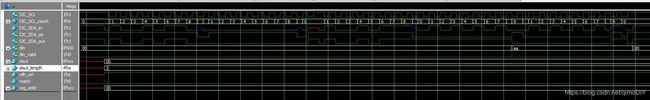

仿真结果

调用仿真脚本得到的结果如下:

和前面介绍的I2C时序比较可以看出是符合预期的,当中的一些蓝色和红色是由于Testbench毕竟不是真实芯片,无法返回完美的确认信号ack,之后可以用ChipScope来观察I2C信号

编译测试

新建一个叫temperature的project,配置为开发板NEXYS4。添加代码文件temperature.v、I2C_transmitter.v、UART_transmitter.v和syn_fifo.v

下一步加入约束constraint文件temperature.xdc,同样这是用标准模板取自己需要部分修改出来的(NEXYS 4 DDR Master XDC):

## This file is a general .xdc for the Nexys4 DDR Rev. C

## To use it in a project:

## - uncomment the lines corresponding to used pins

## - rename the used ports (in each line, after get_ports) according to the top level signal names in the project

## Clock signal

set_property -dict {PACKAGE_PIN E3 IOSTANDARD LVCMOS33} [get_ports clk]

create_clock -period 10.000 -name sys_clk_pin -waveform {0.000 5.000} -add [get_ports clk]

## LEDs

set_property -dict {PACKAGE_PIN H17 IOSTANDARD LVCMOS33} [get_ports {led[0]}]

set_property -dict {PACKAGE_PIN K15 IOSTANDARD LVCMOS33} [get_ports {led[1]}]

##Switches

set_property -dict {PACKAGE_PIN J15 IOSTANDARD LVCMOS33} [get_ports rst]

##Temperature Sensor

set_property -dict {PACKAGE_PIN C14 IOSTANDARD LVCMOS33} [get_ports SCL]

set_property -dict {PACKAGE_PIN C15 IOSTANDARD LVCMOS33} [get_ports SDA]

set_property -dict {PACKAGE_PIN D13 IOSTANDARD LVCMOS33} [get_ports TMP_INT]

set_property -dict {PACKAGE_PIN B14 IOSTANDARD LVCMOS33} [get_ports TMP_CT]

##USB-RS232 Interface

set_property -dict {PACKAGE_PIN C4 IOSTANDARD LVCMOS33} [get_ports RXD]

set_property -dict {PACKAGE_PIN D4 IOSTANDARD LVCMOS33} [get_ports TXD]

set_property -dict {PACKAGE_PIN D3 IOSTANDARD LVCMOS33} [get_ports CTS]

set_property -dict {PACKAGE_PIN E5 IOSTANDARD LVCMOS33} [get_ports RTS]

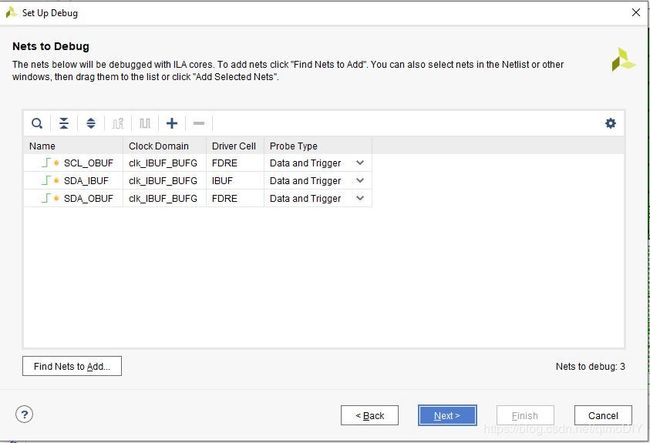

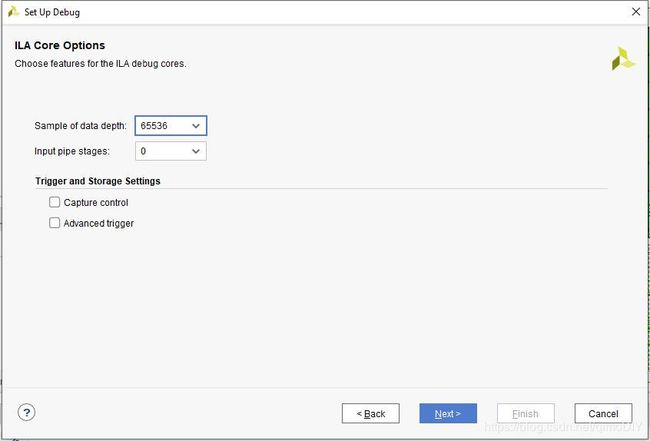

到这里可以点击 Run Synthesis做综合,几分钟完成后用Set Up Debug配置ChipScope,加入和I2C有关的接口SCL和SDA(进出两个口),并设置长度为65536:

下面就可以Run Implementation和Generate Bitstream生成bitstream了。

和前面的教程一样,USB线连接NEXYS4板子,开启Hardware Manager,然后auto连接上板子,Program Device烧写进程序,注意Debug probes file有对应的ltx文件。

结果

打开Putty串口接口,具体配置可以参考教程系列11,分别打入几个指令后收到结果如下:

- 指令00读取温度,返回0x0DC8,根据温度的计算方式,右移3位后除以16,得到温度27.5625摄氏度,当然精度没有这么高,只是计算的结果

- 指令01读取状态寄存器,如同预料的返回0x00

- 指令02读取温度上限的高位,返回了默认值0x20,表示64摄氏度

- 指令03写温度上限的高位为0x0E,表示28摄氏度,不会返回数据

- 再用指令02读取温度上限高位,返回的是刚刚写入的0x0E

- 指令04把温度上限的高位写回0x20

- 再用指令02,读回的是0x20

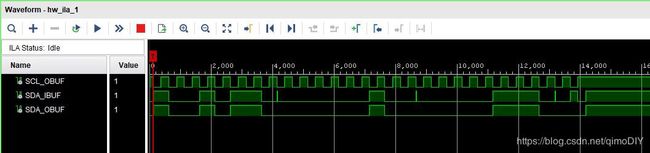

调用ChipScope,设置trigger为SCL的下降沿,分别在putty打入指令0和3显示如下:

这个波形图基本展示了I2C读和写的时序图,就算不是使用FPGA,应该也可以参考这两张图。

总结

没能填上上期说的SD卡的坑,那部分要放到最后。下一篇要介绍板载的加速度传感器accelerometer ADXL362