RT-Thread开发之路(8)— 通过TFTLCD液晶屏幕显示数据

RT-Thread开发之路(8)— 通过TFTLCD液晶屏幕显示数据

一、硬件连接

BearPi上和正点原子的潘多拉开发板上一样,安装了一个1.3寸,分辨率240*240,色彩深度16bit 的SPI通信接口的TFTLCD液晶彩屏,其驱动芯片为ST7789V2,且连接方式都一样采用4线SPI,如下所示,左边是BearPi,右边是atk-pandora的连接图。

二、开启SPI设备

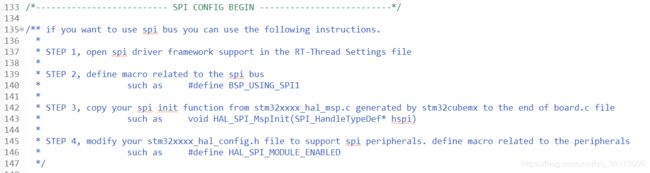

打开board.h文件,找到SPI的配置处,按照其提示配置:

首先,打开【RT-Thread Settings】,找到SPI设备驱动程序,将其选中,然后保存使之生效

通过查看原理图,可以知道,其连接到的引脚如下所示:

| LCD引脚 | MCU引脚 |

|---|---|

| SPI2_MPSI | PC3 |

| SPI2_SCK | PB13 |

| LCD_WR_RS | PC6 |

| LCD_EESET | PC7 |

| LCD_POWER | PB15 |

将board.h的SPI2的注释打开,

接下来使用CubeMx生成HAL_SPI_MspInit()函数,将SPI以及LCD需要的控制引脚设置为如图所示:

将HAL_SPI_MspInit()复制到board.c里

void HAL_SPI_MspInit(SPI_HandleTypeDef* spiHandle)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

if(spiHandle->Instance==SPI2)

{

/* USER CODE BEGIN SPI2_MspInit 0 */

/* USER CODE END SPI2_MspInit 0 */

/* SPI2 clock enable */

__HAL_RCC_SPI2_CLK_ENABLE();

__HAL_RCC_GPIOC_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

/**SPI2 GPIO Configuration

PC3 ------> SPI2_MOSI

PB13 ------> SPI2_SCK

*/

GPIO_InitStruct.Pin = GPIO_PIN_3;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_VERY_HIGH;

GPIO_InitStruct.Alternate = GPIO_AF5_SPI2;

HAL_GPIO_Init(GPIOC, &GPIO_InitStruct);

GPIO_InitStruct.Pin = GPIO_PIN_13;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_VERY_HIGH;

GPIO_InitStruct.Alternate = GPIO_AF5_SPI2;

HAL_GPIO_Init(GPIOB, &GPIO_InitStruct);

/* USER CODE BEGIN SPI2_MspInit 1 */

/* USER CODE END SPI2_MspInit 1 */

}

}

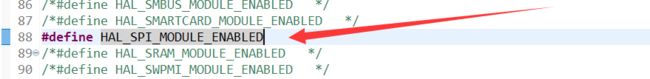

然后打开stm32xxxx_hal_config.h文件,将#define HAL_SPI_MODULE_ENABLED的注释去掉:

然后编译下载运行,在msh下输入list_device,可以看到,spi2已经注册上去了

三、移植LCD代码

在packages文件夹下新建lcd_st7789v2文件夹,并将并将潘多拉开发板IoT_Board的drv_lcd.c、drv_lcd.h、drv_lcd_font.h三个文件放入其中,获取方式为:从 Github 获取 或 从 Gitee 获取。

然后我们需要对drv_lcd.c做一些修改,首先,去掉gpio.h头文件:

然后修改LCD_PWR_PIN,LCD_DC_PIN,LCD_RES_PIN引脚定义:

#define LCD_PWR_PIN GET_PIN(B, 15)

#define LCD_DC_PIN GET_PIN(C, 6)

#define LCD_RES_PIN GET_PIN(C, 7)

接下来,在rt_hw_lcd_config()函数修改两行代码,添加一行代码:

spi_dev_lcd = (struct rt_spi_device *)rt_device_find("spi20"); //修改

cfg.mode = RT_SPI_MASTER | RT_SPI_MODE_2 | RT_SPI_MSB; //修改

spi_dev_lcd->bus->owner = spi_dev_lcd; //添加

然后,我们对rt_hw_lcd_init()需要做比较大的修改,就直接贴上修改完成的代码:

static int rt_hw_lcd_init(void)

{

rt_hw_spi_device_attach("spi2", "spi20", GPIOC, GPIO_PIN_13);

lcd_gpio_init();

rt_thread_mdelay(50);

rt_pin_write(LCD_PWR_PIN, PIN_LOW);

rt_pin_write(LCD_RES_PIN, PIN_LOW);

rt_thread_mdelay(12);

rt_pin_write(LCD_RES_PIN, PIN_HIGH);

rt_pin_write(LCD_PWR_PIN, PIN_LOW);

rt_pin_write(LCD_RES_PIN, PIN_LOW);

rt_thread_mdelay(12);

rt_pin_write(LCD_RES_PIN, PIN_HIGH);

rt_thread_mdelay(12);

/* Sleep Out */

lcd_write_cmd(0x11);

/* wait for power stability */

rt_thread_mdelay(12);

/* Memory Data Access Control */

lcd_write_cmd(0x36);

lcd_write_data(0x00);

/* RGB 5-6-5-bit */

lcd_write_cmd(0x3A);

lcd_write_data(0x65);

/* Porch Setting */

lcd_write_cmd(0xB2);

lcd_write_data(0x0C);

lcd_write_data(0x0C);

lcd_write_data(0x00);

lcd_write_data(0x33);

lcd_write_data(0x33);

/* Gate Control */

lcd_write_cmd(0xB7);

lcd_write_data(0x72);

/* VCOM Setting */

lcd_write_cmd(0xBB);

lcd_write_data(0x3D);

/* LCM Control */

lcd_write_cmd(0xC0);

lcd_write_data(0x2C);

/* VDV and VRH Command Enable */

lcd_write_cmd(0xC2);

lcd_write_data(0x01);

/* VRH Set */

lcd_write_cmd(0xC3);

lcd_write_data(0x19);

/* VDV Set */

lcd_write_cmd(0xC4);

lcd_write_data(0x20);

/* Frame Rate Control in Normal Mode */

lcd_write_cmd(0xC6);

lcd_write_data(0x0F);

/* Power Control 1 */

lcd_write_cmd(0xD0);

lcd_write_data(0xA4);

lcd_write_data(0xA1);

/* Positive Voltage Gamma Control */

lcd_write_cmd(0xE0);

lcd_write_data(0xD0);

lcd_write_data(0x04);

lcd_write_data(0x0D);

lcd_write_data(0x11);

lcd_write_data(0x13);

lcd_write_data(0x2B);

lcd_write_data(0x3F);

lcd_write_data(0x54);

lcd_write_data(0x4C);

lcd_write_data(0x18);

lcd_write_data(0x0D);

lcd_write_data(0x0B);

lcd_write_data(0x1F);

lcd_write_data(0x23);

/* Negative Voltage Gamma Control */

lcd_write_cmd(0xE1);

lcd_write_data(0xD0);

lcd_write_data(0x04);

lcd_write_data(0x0C);

lcd_write_data(0x11);

lcd_write_data(0x13);

lcd_write_data(0x2C);

lcd_write_data(0x3F);

lcd_write_data(0x44);

lcd_write_data(0x51);

lcd_write_data(0x2F);

lcd_write_data(0x1F);

lcd_write_data(0x1F);

lcd_write_data(0x20);

lcd_write_data(0x23);

/* Display Inversion On */

lcd_write_cmd(0x21);

lcd_write_cmd(0x29);

lcd_address_set(0, 0, 240 - 1, 240 - 1);

lcd_clear(WHITE);

/* display on */

rt_pin_write(LCD_PWR_PIN, PIN_HIGH);

return RT_EOK;

}

INIT_COMPONENT_EXPORT(rt_hw_lcd_init);

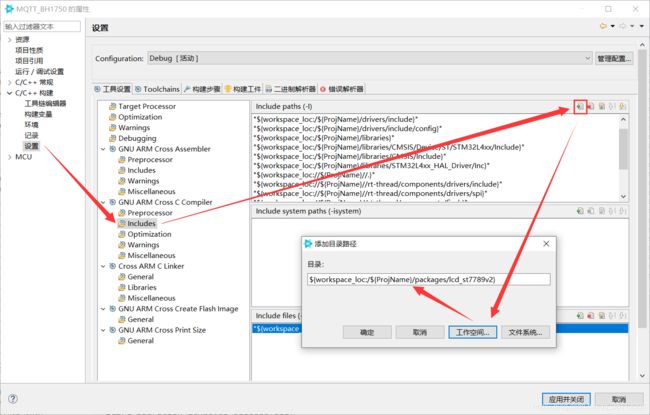

接下来添加头文件,在工具设置配置页,点击GNU ARM Cross C Compiler下的Includes配置项即可打开头文件路径配置参数,点击Inlucde paths(-I)配置栏的添加按钮即将’lcd_st7789v2`目录添加进来,如下图所示:

四、编写代码,在LCD上显示

在main.c里添加头文件,

#include "drv_lcd.h"

然后测试几个函数:

/* 设置背景色和前景色 */

lcd_set_color(WHITE, BLACK);

/* 在 LCD 上显示字符 */

lcd_show_string(10, 60, 32, "Hello!");

lcd_show_string(10, 100, 32, "RT-Thread");

/* 在 LCD 上画线 */

lcd_draw_line(0, 69+16+24+32, 240, 69+16+24+32);

/* 在 LCD 上画一个同心圆 */

lcd_draw_point(120, 194);

for (int i = 0; i < 46; i += 4)

{

lcd_draw_circle(120, 194, i);

}

编译下载运行,可以看到: