TwinCAT3 PLC多轴编程的方法

测试共有13个轴,前10个轴包含基本功能,后3个轴包含独有功能。

方法一

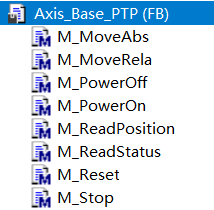

定义每个轴的基本功能,包括上电、下电、走相对、走绝对、读位置、读状态、复位、停止等。

在Axis_Base_PTP中定义变量:

FUNCTION_BLOCK Axis_Base_PTP

VAR

REF: AXIS_REF;

mcMoveRela: MC_MoveRelative;

mcPower: MC_Power;

mcStop: MC_Stop;

mcMoveAbs: MC_MoveAbsolute;

mcReset: MC_Reset;

mcReadPosition: MC_ReadActualPosition;

mcReadStatus: MC_ReadStatus;

mcHalt: MC_Halt;

AxisPara:ST_AxisPara;

END_VAR

M_PowerOn方法代码:

METHOD M_PowerOn : BOOL

VAR_INPUT

bExcute : BOOL;

END_VAR

VAR_OUTPUT

bStatus : BOOL; (* B *)

bBusy : BOOL; (* V *)

bActive : BOOL; (* V *)

bError : BOOL; (* B *)

dErrorID : UDINT; (* E *)

END_VAR

IF bExcute THEN

mcPower(

Axis:= REF,

Enable:= TRUE,

Enable_Positive:= TRUE,

Enable_Negative:= TRUE,

Override:= AxisPara.rOverride,

BufferMode:= ,

Options:= ,

Status=> bStatus,

Busy=> bBusy,

Active=> bActive,

Error=> bError,

ErrorID=> dErrorID);

END_IF

M_MoveRela方法代码:

METHOD M_MoveRela : BOOL

VAR_INPUT

bLimit_1 : BOOL;

bLimit_2 : BOOL;

rDistance : REAL;

rVelocity : REAL;

bExcute : BOOL;

END_VAR

VAR_OUTPUT

bDone : BOOL; (* B *)

bBusy : BOOL; (* V *)

bActive : BOOL; (* V *)

bError : BOOL; (* B *)

dErrorID : UDINT; (* E *)

END_VAR

IF rDistance>0 THEN

mcHalt(

Axis:= REF,

Execute:= bLimit_1,

Deceleration:= AxisPara.Deceleration,

Jerk:= ,

BufferMode:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

IF NOT bLimit_1 THEN

mcMoveRela(

Axis:= REF,

Execute:= bExcute,

Distance:= rDistance,

Velocity:= rVelocity,

Acceleration:= AxisPara.Acceleration,

Deceleration:= AxisPara.Deceleration,

Jerk:= ,

BufferMode:= ,

Options:= ,

Done=> bDone,

Busy=> bBusy,

Active=> bActive,

CommandAborted=> ,

Error=> bError,

ErrorID=> dErrorID);

END_IF

ELSIF rDistance<0 THEN

mcHalt(

Axis:= REF,

Execute:= bLimit_2,

Deceleration:= AxisPara.Deceleration,

Jerk:= ,

BufferMode:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

IF NOT bLimit_2 THEN

mcMoveRela(

Axis:= REF,

Execute:= bExcute,

Distance:= rDistance,

Velocity:= rVelocity,

Acceleration:= AxisPara.Acceleration,

Deceleration:= AxisPara.Deceleration,

Jerk:= ,

BufferMode:= ,

Options:= ,

Done=> bDone,

Busy=> bBusy,

Active=> bActive,

CommandAborted=> ,

Error=> bError,

ErrorID=> dErrorID);

END_IF

END_IF

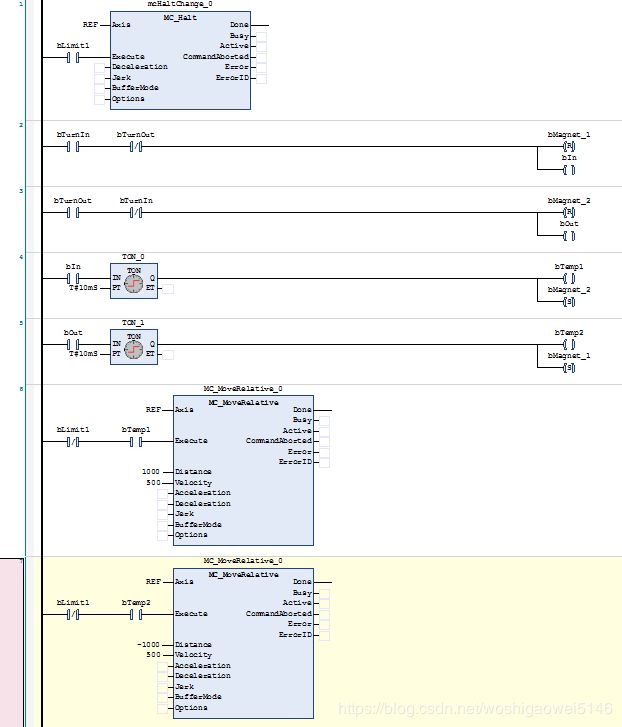

对于附加功能的轴11,继承Axis_Base_PTP,独有的方法M_TurnInOut另外添加。

Axis_Base_PTP继承自基类并定义变量:

FUNCTION_BLOCK Axis11_PTP EXTENDS Axis_Base_PTP

VAR_INPUT

END_VAR

VAR_OUTPUT

bMagnet_1 AT%Q* : BOOL;

bMagnet_2 AT%Q* : BOOL;

END_VAR

VAR

bIn : BOOL :=FALSE;

bOut: BOOL :=FALSE;

TON_0: TON;

TON_1: TON;

bTemp1: BOOL;

bTemp2: BOOL;

MC_MoveRelative_0: MC_MoveRelative;

mcHaltChange_0: MC_Halt;

END_VAR

M_TurnInOut方法代码:

METHOD M_TurnInOut : BOOL

VAR_INPUT

bTurnIn : BOOL;

bTurnOut : BOOL;

bLimit1 : BOOL;

END_VAR

VAR_OUTPUT

END_VAR

在Main函数中定义变量:

//定义接口及继承关系

Axis : ARRAY[1..10] OF Axis_Base_PTP;

Axis11 : Axis11_PTP;

Axis12 : Axis12_PTP;

Axis13 : Axis13_PTP;

//选择电机轴号

iAxisNum AT%I* : UINT;(*电机轴号*)

//定义电机运行相对距离参数

rDistance AT%I* : REAL;(*运动距离*)

rVelocity AT%I* : REAL;(*运动速度*)

//定义结构体

AxisPara:ST_AxisPara;(*轴参数结构体*)

AxisStatus:ST_AxisStatus;(*轴状态结构体*)

PoweronStatus:ST_PoweronStatus; (*上电模块结构体*)

PoweroffStatus:ST_PoweroffStatus;(*下电模块结构体*)

MoveAbsStatus:ST_MoveAbsStatus; (*绝对运动模式结构体*)

MoveRelaStatus:ST_MoveRelaStatus;(*相对运动模式结构体*)

StopStatus:ST_StopStatus;(*停止模块结构体*)

ResetStatus:ST_ResetStatus;(*复位模块结构体*)

ReadPosStatus:ST_ReadPosStatus;(*读取轴位置结构体*)

HomeStatus:ST_HomeStatus;(*寻参模块结构体*)

LimitStatus:ST_LimitStatus;(*限位开关状态*)

//定义指令

bComPowerOn AT%I* : BOOL;(*上电命令*)

bComPowerOff AT%I* : BOOL;(*下电命令*)

bComMoveRela AT%I* : BOOL;(*相对位置指令*)

bComStop AT%I* : BOOL;(*停止指令*)

bComMoveAbs AT%I* : BOOL;(*绝对位置指令*)

bComRest AT%I* : BOOL;(*复位指令*)

bComReadPos AT%I* : BOOL;(*读取当前位置指令*)

bComReadStatus AT%I* : BOOL;(*读取电机状态指令*)

bHome AT%I* : BOOL;(*电机13寻参指令*)

bGlassForward AT%I* : BOOL;(*电机12更换保护玻璃前进*)

bGlassBack AT%I* : BOOL;(*电机12更换保护玻璃后退*)

bTurnIn AT%I* : BOOL;(*电机11转入*)

bTurnOut AT%I* : BOOL;(*电机11转出*)

CASE iAxisNum OF

1:

Axis[1].M_PowerOn(bExcute:=bComPowerOn,bStatus=>PoweronStatus.bStatus,bBusy=>PoweronStatus.bBusy,bActive=>PoweronStatus.bActive,bError=>PoweronStatus.bErr,dErrorID=>PoweronStatus.dErrID);

Axis[1].M_PowerOff(bExcute:=bComPowerOff,bStatus=>PoweroffStatus.bStatus,bBusy=>PoweroffStatus.bBusy,bActive=>PoweroffStatus.bActive,bError=>PoweroffStatus.bErr,dErrorID=>PoweroffStatus.dErrID);

Axis[1].M_MoveAbs(bLimit_1:=LimitStatus.Axis_1_Limit_1,bLimit_2:=LimitStatus.Axis_1_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveAbs,bDone=>MoveAbsStatus.bDone,bBusy=>MoveAbsStatus.bBusy,bActive=>MoveAbsStatus.bActive,bError=>MoveAbsStatus.bErr,dErrorID=>MoveAbsStatus.dErrID);

Axis[1].M_MoveRela(bLimit_1:=LimitStatus.Axis_1_Limit_1,bLimit_2:=LimitStatus.Axis_1_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveRela,bDone=>MoveRelaStatus.bDone,bBusy=>MoveRelaStatus.bBusy,bActive=>MoveRelaStatus.bActive,bError=>MoveRelaStatus.bErr,dErrorID=>MoveRelaStatus.dErrID);

Axis[1].M_Stop(bExcute:=bComStop,bDone=>StopStatus.bDone,bBusy=>StopStatus.bBusy,bActive=>StopStatus.bActive,bError=>StopStatus.bErr,dErrorID=>StopStatus.dErrID);

Axis[1].M_Reset(bExcute:=bComRest,bDone=>ResetStatus.bDone,bBusy=>ResetStatus.bBusy,bError=>ResetStatus.bErr,dErrorID=>ResetStatus.dErrID);

Axis[1].M_ReadPosition(bExcute:=bComReadPos,bValid=>ReadPosStatus.bValid,bBusy=>ReadPosStatus.bBusy,bError=>ReadPosStatus.bErr,dErrorID=>ReadPosStatus.dErrID,lPosition=>ReadPosStatus.lPosition);

Axis[1].M_ReadStatus(bExcute:=bComReadStatus,bValid=>AxisStatus.Axis_Valid,bBusy=>AxisStatus.Axis_Busy,bError=>AxisStatus.Axis_Err,dErrorID=>AxisStatus.Axis_ErrID,bErrorStop=>AxisStatus.Axis_ErrorStop,bDisabled=>AxisStatus.Axis_Disabled,bStopping=>AxisStatus.Axis_Stopping,bStandStill=>AxisStatus.Axis_StandStill,bDiscreteMotion=>AxisStatus.Axis_DiscreteMotion,bContinuousMotion=>AxisStatus.Axis_ContinuousMotion,bSynchronizedMotion=>AxisStatus.Axis_SynchronizedMotion,bHoming=>AxisStatus.Axis_Homing,bConstantVelocity=>AxisStatus.Axis_ConstantVelocity,bAccelerating=>AxisStatus.Axis_Accelerating,bDecelerating=>AxisStatus.Axis_Decelerating);

2:

Axis[2].M_PowerOn(bExcute:=bComPowerOn,bStatus=>PoweronStatus.bStatus,bBusy=>PoweronStatus.bBusy,bActive=>PoweronStatus.bActive,bError=>PoweronStatus.bErr,dErrorID=>PoweronStatus.dErrID);

Axis[2].M_PowerOff(bExcute:=bComPowerOff,bStatus=>PoweroffStatus.bStatus,bBusy=>PoweroffStatus.bBusy,bActive=>PoweroffStatus.bActive,bError=>PoweroffStatus.bErr,dErrorID=>PoweroffStatus.dErrID);

Axis[2].M_MoveAbs(bLimit_1:=LimitStatus.Axis_2_Limit_1,bLimit_2:=LimitStatus.Axis_2_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveAbs,bDone=>MoveAbsStatus.bDone,bBusy=>MoveAbsStatus.bBusy,bActive=>MoveAbsStatus.bActive,bError=>MoveAbsStatus.bErr,dErrorID=>MoveAbsStatus.dErrID);

Axis[2].M_MoveRela(bLimit_1:=LimitStatus.Axis_2_Limit_1,bLimit_2:=LimitStatus.Axis_2_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveRela,bDone=>MoveRelaStatus.bDone,bBusy=>MoveRelaStatus.bBusy,bActive=>MoveRelaStatus.bActive,bError=>MoveRelaStatus.bErr,dErrorID=>MoveRelaStatus.dErrID);

Axis[2].M_Stop(bExcute:=bComStop,bDone=>StopStatus.bDone,bBusy=>StopStatus.bBusy,bActive=>StopStatus.bActive,bError=>StopStatus.bErr,dErrorID=>StopStatus.dErrID);

Axis[2].M_Reset(bExcute:=bComRest,bDone=>ResetStatus.bDone,bBusy=>ResetStatus.bBusy,bError=>ResetStatus.bErr,dErrorID=>ResetStatus.dErrID);

Axis[2].M_ReadPosition(bExcute:=bComReadPos,bValid=>ReadPosStatus.bValid,bBusy=>ReadPosStatus.bBusy,bError=>ReadPosStatus.bErr,dErrorID=>ReadPosStatus.dErrID,lPosition=>ReadPosStatus.lPosition);

Axis[2].M_ReadStatus(bExcute:=bComReadStatus,bValid=>AxisStatus.Axis_Valid,bBusy=>AxisStatus.Axis_Busy,bError=>AxisStatus.Axis_Err,dErrorID=>AxisStatus.Axis_ErrID,bErrorStop=>AxisStatus.Axis_ErrorStop,bDisabled=>AxisStatus.Axis_Disabled,bStopping=>AxisStatus.Axis_Stopping,bStandStill=>AxisStatus.Axis_StandStill,bDiscreteMotion=>AxisStatus.Axis_DiscreteMotion,bContinuousMotion=>AxisStatus.Axis_ContinuousMotion,bSynchronizedMotion=>AxisStatus.Axis_SynchronizedMotion,bHoming=>AxisStatus.Axis_Homing,bConstantVelocity=>AxisStatus.Axis_ConstantVelocity,bAccelerating=>AxisStatus.Axis_Accelerating,bDecelerating=>AxisStatus.Axis_Decelerating);

……………………

13:

Axis13.M_PowerOn(bExcute:=bComPowerOn,bStatus=>PoweronStatus.bStatus,bBusy=>PoweronStatus.bBusy,bActive=>PoweronStatus.bActive,bError=>PoweronStatus.bErr,dErrorID=>PoweronStatus.dErrID);

Axis13.M_PowerOff(bExcute:=bComPowerOff,bStatus=>PoweroffStatus.bStatus,bBusy=>PoweroffStatus.bBusy,bActive=>PoweroffStatus.bActive,bError=>PoweroffStatus.bErr,dErrorID=>PoweroffStatus.dErrID);

Axis13.M_MoveAbs(bLimit_1:=LimitStatus.Axis_13_Limit_1,bLimit_2:=LimitStatus.Axis_13_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveAbs,bDone=>MoveAbsStatus.bDone,bBusy=>MoveAbsStatus.bBusy,bActive=>MoveAbsStatus.bActive,bError=>MoveAbsStatus.bErr,dErrorID=>MoveAbsStatus.dErrID);

Axis13.M_MoveRela(bLimit_1:=LimitStatus.Axis_13_Limit_1,bLimit_2:=LimitStatus.Axis_13_Limit_2,rDistance:=rDistance,rVelocity:=rVelocity,bExcute:=bComMoveRela,bDone=>MoveRelaStatus.bDone,bBusy=>MoveRelaStatus.bBusy,bActive=>MoveRelaStatus.bActive,bError=>MoveRelaStatus.bErr,dErrorID=>MoveRelaStatus.dErrID);

Axis13.M_Stop(bExcute:=bComStop,bDone=>StopStatus.bDone,bBusy=>StopStatus.bBusy,bActive=>StopStatus.bActive,bError=>StopStatus.bErr,dErrorID=>StopStatus.dErrID);

Axis13.M_Reset(bExcute:=bComRest,bDone=>ResetStatus.bDone,bBusy=>ResetStatus.bBusy,bError=>ResetStatus.bErr,dErrorID=>ResetStatus.dErrID);

Axis13.M_ReadPosition(bExcute:=bComReadPos,bValid=>ReadPosStatus.bValid,bBusy=>ReadPosStatus.bBusy,bError=>ReadPosStatus.bErr,dErrorID=>ReadPosStatus.dErrID,lPosition=>ReadPosStatus.lPosition);

Axis13.M_ReadStatus(bExcute:=bComReadStatus,bValid=>AxisStatus.Axis_Valid,bBusy=>AxisStatus.Axis_Busy,bError=>AxisStatus.Axis_Err,dErrorID=>AxisStatus.Axis_ErrID,bErrorStop=>AxisStatus.Axis_ErrorStop,bDisabled=>AxisStatus.Axis_Disabled,bStopping=>AxisStatus.Axis_Stopping,bStandStill=>AxisStatus.Axis_StandStill,bDiscreteMotion=>AxisStatus.Axis_DiscreteMotion,bContinuousMotion=>AxisStatus.Axis_ContinuousMotion,bSynchronizedMotion=>AxisStatus.Axis_SynchronizedMotion,bHoming=>AxisStatus.Axis_Homing,bConstantVelocity=>AxisStatus.Axis_ConstantVelocity,bAccelerating=>AxisStatus.Axis_Accelerating,bDecelerating=>AxisStatus.Axis_Decelerating);

Axis13.M_Home(bExcute:=bHome,bCalibrationCam:=Axis_13_CaliCam,bDone=>HomeStatus.bDone,bBusy=>HomeStatus.bBusy,bActive=>HomeStatus.bActive,bError=>HomeStatus.bErr,dErrorID=>HomeStatus.dErrID);

END_CASE

运行时,先输入iAxisNum,再执行命令即可。

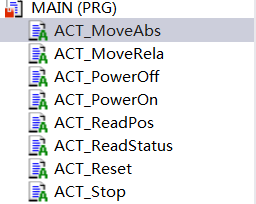

方法二

定义轴基本功能,同上。区别在于Main主函数:

在Main中添加Action

ACT_PowerOn方法代码,其余类似。

FOR i:=1 TO 13 DO

Axis[i].M_PowerOn(bExcute:=cmdPowerOn[i],bStatus=>PoweronStatus.bStatus,bBusy=>PoweronStatus.bBusy,bActive=>PoweronStatus.bActive,bError=>PoweronStatus.bErr,dErrorID=>PoweronStatus.dErrID);

END_FOR

Main函数代码:

//定义接口及继承关系

Axis : ARRAY[1..10] OF Axis_Base_PTP;

Axis11 : Axis11_PTP;

Axis12 : Axis12_PTP;

Axis13 : Axis13_PTP;

cmdPowerOn AT%I* : ARRAY[1..13] OF BOOL;

cmdPowerOff AT%I* : ARRAY[1..13] OF BOOL;

cmdMoveRela AT%I* : ARRAY[1..13] OF BOOL;

cmdMoveAbs AT%I* : ARRAY[1..13] OF BOOL;

cmdReset AT%I* : ARRAY[1..13] OF BOOL;

cmdStop AT%I* : ARRAY[1..13] OF BOOL;

cmdReadPos AT%I* : ARRAY[1..13] OF BOOL;

cmdReadStatus AT%I* : ARRAY[1..13] OF BOOL;

cmdHome AT%I* : BOOL;

cmdGlassForward AT%I* : BOOL;

cmdGlassBack AT%I* : BOOL;

cmdTurnIn AT%I* : BOOL;

cmdTurnOut AT%I* : BOOL;

主函数调用Action方法进行轮询:

ACT_PowerOn();

ACT_PowerOff();

ACT_MoveAbs();

ACT_MoveRela();

ACT_Reset();

ACT_Stop();

ACT_ReadPos();

ACT_ReadStatus();

运行时,需针对每个轴的每个指令进行下发。

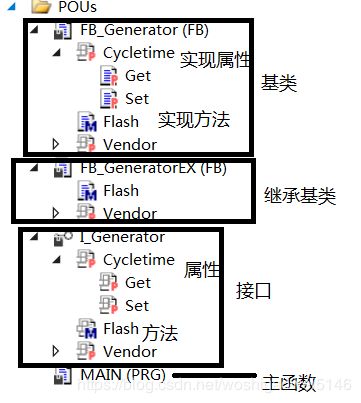

方法三

利用面向对象中的接口和继承方法。借鉴示例。

首先定义接口及属性方法,定义一个基类实现接口中的属性和方法,若需要再定义类继承基类。

Main函数;

PROGRAM MAIN

VAR

fbGenerator1 : FB_Generator;

fbGenerator2 : FB_GeneratorEX;

iGenerator : I_Generator;

tCycletime: TIME :=T#3S;

sVendor: STRING;

change: BOOL :=TRUE;

output: BOOL;

END_VAR

IF change THEN

iGenerator:=fbGenerator1;

ELSE

iGenerator:=fbGenerator2;

END_IF

output:=iGenerator.Flash();

iGenerator.Cycletime:=tcycletime;

sVendor:=iGenerator.Vendor;

运行时,通过接口切换调用不同轴模块。

优缺点比较

方法一:上位机调用变量较少,主程序复杂;

方法二:上位机调用变量较多,主程序简单;

方法三:上位机调用变量较少,主程序轴联动复杂;