【开源电机驱动】使用电气等效对机械系统建模

原文地址:http://www.modularcircuits.com/blog/articles/bridge-to-the-far-side/modeling-mechanical-systems/

本文为译者翻译校正稿件,含有译者个人理解和标注

Modeling mechanical systems

机械系统建模

1.Introduction

引言

Previously we’ve used a relatively ad-hoc approach to come up with mechanical models and their electrical equivalents. While that approach works for simple systems, it quickly becomes error-prone. In this article I will describe a more systematic approach that can be used to analyze mechanical systems alone, or combined electro-mechanical systems together.

在之前的电机建模一节,我们已经使用了一个相对特殊的方法来提出机械模型和他们在电气领域的等效模型。虽然这种方法适用于简单的系统,但它并不是普遍适用的。在本文中,我将展示一个更系统化的方法,它可以单独用于机械系统的分析,或者机电系统的结合体的分析。

In the end, the circuits derived with this method can also be used in for example circuit simulators to analyze and simulate behavior, but the results are easy to relate back to the mechanical world.

用这种方法导出的电路可以用于电路分析和仿真,其仿真分析果很容易与机械领域的特性联系起来。

Another important benefit is that this model preserves enough of the mechanical details that mechanical systems can easily be cascaded as we’ll see in the examples.

另一个显著的优点是,这个模型保留了足够多的机械细节,机械系统可以很容易地级联在一起,正如我们将在示例中展示的一样。

Finally, the description here can easily be adopted for other electro-mechanical devices than motors: speakers, microphones, even MEMS devices, like accelerometers or gyroscopes.

最后,这里的转换方法可以很容易地应用于除马达之外的其他电子设备:比如扬声器,麦克风等,甚至也能应用在微机电系统设备中,比如加速度计或着陀螺仪。

The method I’ll introduce here will deal with 1DOF, rotational mechanical systems. It is easy to develop a similar model for 1DOF translational systems as well.

我在这里首先介绍处理一自由度,转动机械系统的方法。对于一维平动系统,建立相似模型是很容易的。

2.Mechanical Schematics

机械原理图

We start the discussion with a way of describing (1DOF, rotational) mechanical systems similar to the way we do it with electrical circuits: by drawing a schematic representation of it. The goal is to develop a method that represent the topology (connection) and the various components that make up a mechanical system, but hiding all the details of actual construction, size, implementation detail etc. In order to do so, we’ll have to introduce a way to extract the components and their connections. I will roughly follow the description used here:

我们对如何描述(1维,自转)机械系统开始讨论,类似于我们对电路的描述: 在电路图中,我们使用示意图代表特定元件。我们现在的目的是使用一种方法来表示拓扑(连接)以及表示机械系统的各种组件,但是它隐藏了机械结构的实际的大小、实现细节等。为了做到这一点,我们必须引入一种方法来提取组件及其连接。我将大致遵循这里的表述:

http://lpsa.swarthmore.edu/Systems/MechRotating/RotMechSysElem.html

but as usual, I will make some changes to make my points more clear.

但是像往常一样,我会做一点修改,从而使我的观点更加清晰。

Just as with electrical systems, our mechanical schematics will be special graphs: comprised of nodes and connections (or vertices). We will put special notations on these elements and assign special meaning to them to describe things.

就像电气系统一样,我们的机械图表将由特殊的图形表示: 由节点(或顶点)和线组成。我们将在这些元素上加上特殊的标记,并赋予它们特定的含义。

2.1Nodes

节点

In electrical design, we choose to represent points that share the same potential with nodes (occasionally we extend nodes with lines to make the schematic more readable, but that’s irrelevant here). We also choose to represent current flows by placing connections between these nodes and draw symbols on these connections that describe the relationship between the current and the potential-difference (voltage) between the two nodes they connect. Please understand that while this representation feels natural, it is actually arbitrary and we could just as well as go the other way around (see dual graphs for an idea on how) and get a completely useable model as well.

在电气原理图中,我们使用点(Node)表示潜在相通的点(偶尔我们用线扩展节点,使示意图更具可读性,但与这里不相关)。我们还选择通过在这些节点之间放置连接线(Line)来表示电流流向,并在这些连接线上绘制符号(例如VCC)来描述它们连接的两个节点之间的电流和电位差(电压)之间的关系。需要解释的是,虽然这种表示看起来很自然,但它实际上是任意的,我们也可以反很随意(译者的理解是,用节点和线表示电气连接,会有很多种方式,它并不是唯一的) ,并得到一个完全可用的模型。

In our mechanical world, we also have two measurable properties to deal with: torque and rotational velocity (speed), In systems with only 1DOF, both of these quantities are scalars, just as voltage and current are in electrical systems. The representation that I’ll use in this explanation will be such that I use nodes to represent points that share the same speed – shafts for the most cases. Wherever torque can transfer from one shaft to another, I will draw connections between the corresponding nodes, and I’ll place symbols on these connections to describe the relationship between the torque and the speed-difference between the two nodes these vertices connect.

在我们的机械世界中,我们还有两个可测量的参数要处理: 扭矩和速度(转速)。在只有一个自由度的系统中,这两个量都是标量,就像电力系统中的电压和电流一样。在这里我们的描述中,我将使用节点来表示在大多数情况下共享具有相同速度的轴的点。当扭矩可以从一个轴传递到另一个轴时,我会画出相应节点之间的连接,我会在这些连接上放置符号,来描述扭矩和这些顶点连接的两个节点之间的速度差关系。

While this representation is also arbitrary, it also feels at least somewhat natural: the nodes abstract shafts, that connect components that rotate together at the same rate.

虽然这种表示也是任意的,但至少感觉比较自然: 节点抽象为联轴器,以连接相同速率的旋转组件。

2.2GROUND

地

There’s one special node in both electrical and mechanical systems that are worth mentioning: the ground point. This is the node with 0 potential in an electrical system and serves as a reference to measure all other potentials in the system. It reflects the fact that the electrical field – at least the ones we care about in electrical schematics – is conservative.

在电气和机械系统中有一个特殊的节点值得一提: 接地点。在电子系统中它是0电位的节点,作为测量系统中所有其他电位的参考。它反映了这样一个事实: 电场——至少是我们在电气原理图中所关心的电场——是保守的。

In the mechanical world, there’s also a special node like that, a node which has 0 speed. It also serves as a reference to measure all other speeds in the system and expresses the fact that we operate in an inertial reference frame.

在机械世界里,也有类似的特殊节点,那就是速度为0的节点。它也可以作为测量系统中所有其他速度的参考,并且表达了我们在惯性参考系中工作的事实。

In the following I’ll denote this special note with this symbol:

在下面,我将用这个符号来表示这个特殊的注释:

![]()

Just as with electronics, if multiple ground symbols are in a schematic, the interpretation is that all such places are in fact connected to the same, unique ground node.

就像电子学一样,如果在示意图中有多个地面符号,那么解释就是所有这些地实际上都连接到同一个唯一的地节点。

3.Mechanical component characteristics

机械部件特性

Mechanical components in our model have two external phenomena effecting them: speed (rotational velocity) and torque. All of these elements have some internal characteristics, describing their response to these external effects. These characteristic equations are different for each type of component, but in general establish a relationship between torque and speed on the mechanical component. Let’s see a few of these components!

我们模型中的机械部件有两个外部现象在影响它们: 速度(转速)和扭矩。所有这些因素都有一些内在的特征,描述了它们对这些外部影响的反应。这些特征方程对于不同类型的部件是不同的,但是一般来说在机械部件上建立了扭矩和速度之间的关系。让我们看看其中的一些组件!

DAMPING

阻尼

Viscous friction, or damping is probably the simplest of all mechanical component to model. This component acts as a loss and it introduces a torque on the shaft that is proportional to the speed of the rotation. The torque introduced by is in the opposite direction to the rotation of the shaft as damping drains energy out of the system. In the following however we’re going to look at the components from the systems’ perspective. In that view, we need to ‘feed’ some torque into the component to compensate for its internal torque. Because of that, I leave the negative sign out:

粘性摩擦或阻尼可能是所有机械部件中最简单的建模方法。这个部件表征了损失,它在轴上引入了一个与旋转速度成正比的扭矩。当阻尼将能量从系统中排出时,引入的扭矩与轴的旋转方向相反。下面我们将从系统的角度来看这些组件:我们需要向部件“输入”一些扭矩,以补偿其内部扭矩。正因为如此,我把负号省略了:

T = Kd * s,其中 Kd 是一个常数,描述了分量的损耗。

I will use this symbol to represent damping components:

我将使用这个符号来表示阻尼部件:

![]()

As you can see, this component has two connections, so it supposed to connect two shafts. It is there to model the fact that all types of friction, including damping is a relative phenomena: friction acts between two bodies which move at different speeds relative to each other.

正如你所看到的,这个部件有两个连接位置,所以它应该连接两个轴。它模拟了所有类型的摩擦,包含一个相对的阻尼现象: 摩擦作用于两个相对运动速度不同的物体之间。

KINETIC FRICTION

动摩擦

Kinetic friction or friction in short introduces a constant torque that counter-acts the speed of the shaft. As we will use it in the discussion below, friction is only slightly non-linear:

简而言之,动摩擦引入了一个恒定的扭矩,影响轴的速度(动摩擦产生的扭矩将会降低速度)。正如我们将在下面的讨论中所说的那样,摩擦力只是轻微的非线性:

T = sign(s) * Kf, 其中 Kf 是描述元件损失的常数

The sign of the torque is again viewed from the systems’ perspective. The symbol I’ll use for this type of friction is the following:

扭矩的符号也是从系统的角度来定义的。我将用以下符号来表示这种摩擦力:

![]()

The reason I say that friction is only slightly non-linear is that if we assume that the shaft is rotating in one (let’s say positive) direction only, the torque on the friction is going to be constant.

我之所以说摩擦力只是轻微的非线性,是因为我们假设轴只沿着一个方向旋转,因此摩擦力矩是恒定的。

STATIC FRICTION

静态摩擦

Static friction is an even more non-linear element than its kinetic brethren. The best way of describing it in our representation is as follows: the speed-difference between the two ends of it is 0 as long as the torque is under a certain (absolute) limit – it acts as a ‘short circuit’. When the torque reaches that certain limit, the component ‘disappears’ completely and doesn’t enforce any relationship between the speeds of its two ends. At that point it doesn’t ‘consume’ any torque either, so it becomes an ‘open circuit’. It stays in that ‘open’ state as long as the speed-difference reaches 0 again, at which point it ‘locks’ and returns to the ‘short circuit’ behavior. The equations describing this behavior are the following:

静摩擦是一种比动摩擦更为非线性的元素。在我们的表示方法中是这样描述它的: 只要扭矩在一定(绝对)极限下,它的两端之间的速度差是0——它起到了“短路”的作用。当扭矩达到某个极限时,这个部件就完全消失了,它的两端的速度之间没有任何关系。在这个状态下,它不消耗任何扭矩,所以它此时是开路的。它会一直处于“开路”状态直到速度差再次达到0,此时它会“锁定”并返回到“短路”状态。描述这种行为的方程如下:

s = 0 if abs(T) < d; T = 0 if s > 0

静摩擦只有在速度差为0的时候才会产生一个扭矩.

Please note, that this type of friction is not only non-linear but a hysteretic element as well. It has two states and it switches between them not only depending on its current conditions but on past history as well. This behavior makes it particularly hard to work with and in many models assumptions are made as to which state static friction is in, and is assumed to never change state.

请注意,这种类型的摩擦不仅是非线性的,而且也是一种滞后的元素。它有两种状态且在两种状态之间切换,不仅取决于当前的状态,也取决于过去的状态。这种情况特别难以处理,在许多模型中,通常假设静摩擦处于某种状态,并且它的状态永远不会改变。

The symbol for static friction is:

静摩擦的符号是:

![]()

MASS

质量

A rotating mass resist changes in speed or acceleration, so the torque it introduces will be proportional to the derivative of the speed. The characteristic equation is the following:

一个旋转的质量块阻碍了速度或加速度的变化,因此它所引入的扭矩与速度的导数成正比。特征方程如下:

T = J * (ds/dt), 其中 J是转动惯量

The symbolic representation will be the following:

符号表示如下:

![]()

Now, here’s one curiosity: why does mass have two connections? The answer is that while mass or inertia isn’t relative, classical mechanical systems are. They can only be interpreted in a so-called inertial reference frame. Movement of masses (consequently their speed or acceleration) is always relative to the chosen reference frame. We denote this reference frame with the ground node so, one of the connection of the mass symbol is always connected to this ground node.

现在,有一个有趣的问题是: 为什么质量有两个连接点?答案是,虽然质量和惯性不是相对的,但经典的力学系统是相对的。它们只能在所谓的惯性参照系中解释。质量的运动(因此它们的速度或加速度)总是相对于所选择的参考系。我们用地面节点来表示这个参考框架,这样,质量符号的连接之一总是连接到地面节点。

SPRINGS

弹簧

Let’s also take a look at the other reactive element in mechanical designs: the spring. Springs exert a force (or torque in a rotational system) that’s proportional to displacement or the integral of the speed as opposed to the speed itself. Here we talk about displacement or speed in relative terms: the displacement of one end of the sprig relative to the other. Another way of stating this is that the change of the torque of a sprint is proportional to the speed:

让我们来看看机械设计中的另一个无功元件: 弹簧。弹簧施加的力(或转动系统中的扭矩)与位移或速度的积分成正比,与速度本身成反比。这里我们用相对的术语来讨论位移或速度: 弹簧的一端相对于另一端的位移。另一种说法是,冲刺时力矩的变化与速度成正比:

dT/dt = K * s 其中 k 是弹簧常数

The symbol for it will be:

它的符号将是:

![]()

TORQUE SOURCE

扭矩源

Now that we’re done with the passive elements, lets introduce some active ones as well. These would be components that somehow (form an external source) pump mechanical energy into the system. The first type we’ll introduce is a torque source. This puts a constant torque into a system, independent of its speed:

现在我们已经表示完成了被动元件,让我们引入一些主动元件。这些部件以某种方式(形成一个外部来源)将机械能泵入系统。我们将介绍的第一种类型是扭矩源。这就为系统提供了一个不受速度影响的恒定转矩:

T = Ts

It is represented by this symbol:

这个符号表示:

![]()

If I want to emphasize that the torque introduced by the component is a function of something, I’ll use the controlled torque source symbol:

如果我想强调组件引入的扭矩是某种功能的话,我会使用受控扭矩源符号来表示:

![]()

SPEED SOURCE

速度源

The final component that I’ll introduce for now is the speed source. This, as it’s name shows introduces a constant (relative) speed into the system independent of how much torque it takes to do so:

现在我要介绍的最后一个组件是速度源。正如它的名字所显示的那样,它向系统中引入了一个恒定(相对)的速度,与它需要多少扭矩无关:

S = Ss

It’s symbols for simple and controlled cases are:

恒定和受控速度源的符号如下:

![]()

![]()

Now it’s important to understand that all of these components, but especially the sources are highly idealized. They are good as building blocks and for theoretical discussions but they are not much more than rough first approximations of actual physical components.

现在重要的是要理解所有这些组成部分,特别是它们的来源是高度理想化的。在理论讨论时它们是很好的构建模型,但它们不过是实际物理成分粗略的近似。

Circuit laws

电路法则

The last thing we will have to establish is some laws that govern our schematics. In electronics, these are the Kirchhoff’s circuit laws and we’ll need the equivalents as well. The two similar laws for us are the following:

我们最后要建立一些规则来管理我们的图表。在电子学中,这些是基尔霍夫电路定律,我们在机械系统中也需要类似的东西。对我们来说,这两条类似的规则如下:

1: For any node in the system the sum of the torque through all connecting elements to that node is 0.

1: 对于系统中的任何节点,通过所有连接单元到该节点的扭矩之和为0。

This law essentially a re-statement of Newton’s third law in a rotational system.

这个定律实质上是对旋转系统中牛顿第三定律的重述。

2: For any loop in the system the sum of the speed-differences on all the elements making that loop is 0.

2: 对于系统中的任何一个循环,构成该循环的所有元件的速度差之和为0。

This second law is a consequence of us working in an inertial reference frame.

第二定律是我们在惯性参照系中工作的结果。

4.An Example: Revisiting the DC motor

一个例子: 重新考虑直流电动机

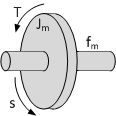

Well, that was dry, but finally we’re at the point to put all that in use! Let’s take another look at our old DC motor. The mechanical side is usually modeled by a rotating disc and some friction:

好吧,这些都是干货,但最后我们的重点在于,如何使用所有他们!让我们再看一下之前的直流电动机。机械模型通常由一个旋转的圆盘和一个带摩擦的轴来表示:

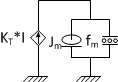

Let’s use our newly acquired knowledge and draw a mechanical schematic representation of it! We have two mechanical components to consider: the rotating mass and the friction. These two components are connected to the same shaft, so the one end of the two symbols are connected together:

让我们利用我们新学到的知识,画一张机械图表来表示它!我们要考虑两个机械部件: 旋转质量和摩擦力。这两个部件连接在同一个轴上,所以两个符号的一端连接在一起:

But what happens with the other end? Well, for the mass it’s connected to ground as all masses in a mechanical system are, but what about the friction? Remember what we model with this fiction is the mechanical losses, mostly in the bearings. The other end of these bearings is tied to the casing of the motor, so the other ‘shaft’ that this fiction component is connected to is the housing of the motor. If we assume that the housing of the motor is stationary, it doesn’t rotate relative to ground. If that’s the case, we can model the friction as if is connected to ground as well:

但是另一端呢?对于质量来说,它和地面相连,就像机械系统中所有的质量一样,但是摩擦力呢?请记住,我们的模型模拟的是机械损失,主要在轴承上。这些轴承的另一端连接到电机外壳上,所以这个虚构部件连接到的另一个‘轴’是电机的外壳。如果我们假设发动机的外壳是静止的,不会相对于地面旋转。那么,我们可以把摩擦力另一端模拟为与地面相连:

There are two things missing: the source of the mechanical energy and the mechanical load. If we model the motor alone, the load is simple: we don’t have it. The source isn’t that complex either: it is the torque converted by the motor. This torque is acting between the shaft and the housing of the motor, and as we’ve discussed before, the we assume that the motor housing is stationary:

这里缺少两样东西: 机械能的来源和机械的负载。如果我们单独模拟电机,负载会很简单: 没有负载。电源也没有那么复杂: 它是由电动机转换而来的转矩。这个转矩作用于电机的轴和外壳之间,正如我们之前讨论过的,我们假设电机外壳是静止的:

This model can be used (using the circuit laws above) to reason about all sorts of things. For example:

这个模型可以用来(利用上面的电路定律)推理各种各样的事情。例如:

There are two nodes in the system (the motor shaft and ground). Consequently all three mechanical components are connected in parallel. This means that all share the same speed, but the torque on them is different. Of course the torque on the source is constant (KT*I), and in our model, friction also has a constant torque at least as long as the direction of the motion doesn’t change. So, some of the torque converted by the motor is used up in the friction, the rest will appear on the mass. If you look at the characteristic equation for the mass however:

系统中有两个节点(电机轴和地面)。因此,三个机械部件都是并联的。这意味着它们都有相同的速度,但是在它们上产生的扭矩是不同的。当然,源上的扭矩是恒定的(KT * I) ,在我们的模型中,摩擦力也有一个恒定的扭矩,至少在运动方向不变的情况下它是恒定的。所以,一部分由电机转换的扭矩在摩擦中用被消耗了,剩下的就留在在质量块上。然而,如果你再看一下质量的特征方程:

T = Jm * (ds/dt)

You’ll see that constant torque will create a constant change (acceleration if it’s positive) in speed. Neither the friction nor the torque source put any other constraints on the speed, so the speed will in deed start changing. The torque on the torque source is proportional to the current in the motor windings, so we get the following:

你会看到恒定的转矩会产生恒定的速度变化(如果是正加速度)。摩擦力和扭矩源都没有对速度施加任何其他约束,所以速度实际上会开始变化。扭矩源上的扭矩与电机绕组中的电流成正比,所以我们得到了以下结果:

If we put a constant current through the motor, we should see a constant acceleration on the shaft.

如果我们让恒定的电流通过马达,我们就会看到轴上有恒定的加速度。

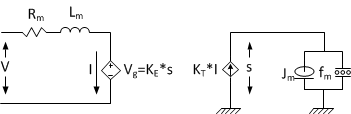

Well, that can’t be accurate, can it? Have you ever seen a motor keep accelerating forever, even if we don’t have any load in its shaft? No, of course not, and we’ll see in a minute why! The first thing that should be easy to see is that we don’t usually put a constant current through the motor, but a constant voltage. The other thing should be mentioned however is the whole electrical side of the motor: the inductor, the internal resistance, and the generator voltage. A motor model isn’t complete without them:

那不可能是精确的,对吗?你由没有见过轴上没有任何负载的马达不停地在加速?不可能,当然不可能,我们马上就知道为什么了!首先,我们通常不会给电机施加一个恒定的电流,而是一个恒定的电压。另外还有电机的电气参数: 电感,内部电阻,和发电机电压。它们不能被遗忘,没有它们,汽车模型是不完整的,加上这些,我们的模型如下图:

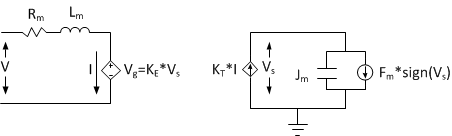

At first it looks quite a bit complicated, but in fact it really isn’t: it only makes the electrical/mechanical conversion in the motor explicit. It shows both the controlled voltage source (which is the conversion in the mechanical –> electrical direction) and the controlled torque source (which is the conversion in the electrical –> mechanical direction).

它看起来似乎有点复杂了,但实际上没有: 它使得电机中的电能/机械转换变得清晰。它既是受控电压源(即机械->电气的转换) ,也是受控扭矩源(即电气->机械的转换)。

Now, if we look at the complete picture, and imagine the idle state, where no voltage is applied and the shaft is not rotating, than apply a constant voltage (V) to the motor, the following will happen:

现在,如果我们完整的来看,想象一下怠速状态下,没有给电机施加电压,轴也没有转动,然后给电机施加一个恒定的电压(v) ,会发生以下情况:

1.The motor current starts increasing linearly due to the inductance. For now, you have to believe me that the time constants on the mechanical side are much higher than on the electrical side, so Vg remains close to 0 (the shaft doesn’t start rotating fast enough) long enough that the current reaches its maximum, where all the input voltage is dropped on the internal resistance (Rm). During this time, the current raises exponentially in the circuit.

由于电感的作用,电机电流开始线性增加。现在,你们必须相信,机械侧的时间常数,比电子侧的要高得多,所以Vg 保持在接近0的状态(轴转动不够快的时候),当电流达到其最大值,所有的输入电压降都在内部电阻(Rm)上. 在此期间,电路中的电流呈指数级上升。

2.This exponential rise in current will translate into an exponential rise in torque on the torque source. Now our friction model is not accurate enough to represent the case where the torque sourced is lower than the torque consumed by the friction, yet the shaft is not moving – that would be modeled by a static friction component – but for now, let’s ignore that little detail, and assume that the torque source pretty soon reaches torque values that are higher than the torque consumed by friction (fm). This torque will start accelerating the mass of the motor, but – and again you’ll have to take my word for it here – it reaches its maximum before it can speed up the mass by any significant amount.

电流的这种指数上升将转化为扭矩源上扭矩的指数增长。现在,我们的摩擦模型不够精确,不能够表示扭矩源低于摩擦消耗的扭矩的情况,然而轴却没有运动——这将由一个静态摩擦分量来模拟——但是现在,让我们忽略这个小细节,并假设扭矩源很快就高于摩擦消耗(fm)的扭矩值,这个力矩将开始加速马达的质量,但是——再一次你必须相信我这里的话——它达到它的最大值之前,它可以加速任何数量的质量.

3.At this point, the maximum current is flowing through the motor and the mass slowly starts accelerating. The electrical transient is over, now the combined electro-mechanical one follows. As we’ve discussed before a constant current generates a constant acceleration on the mass, and that is exactly what’s happening in the beginning. However as soon as the shaft starts rotating, it will introduce a generator voltage (Vg = Ke*s), that starts counter-acting the source voltage (V).

在这个状态点上,最大的电流通过马达,质量慢慢开始加速。电的瞬变过程结束了,机电结合的瞬变过程随之而来。正如我们之前讨论过的,恒定电流对质量产生恒定加速度,这正是刚开始时发生的情况。然而,一旦轴开始旋转,它将引入一个发电机电压(Vg = Ke*s).开始反作用于源电压(V).

4.As the speed increases, so does the generator voltage (Vg), and as Vg rises, less and less voltage drops on the resistor. As a consequence, the current through the motor will start falling, and as it does, so does the torque on the mechanical side. Less torque generates less acceleration on the mass, which means less change in speed, which translates slower rise in Vg on the electrical side.

随着转速增加,反电势(Vg)随之增加,电阻器上的电压降越来越小。因此,通过电机的电流将开始下降(反电势阻碍电流通过电机),同时,机械侧的扭矩也开始下降。扭矩越小,质量上的加速度越小,这意味着速度变化的变化也越小,这就意味着电气侧Vg的上升速度也就越慢。.

5.The result of this interaction is another exponential transient, where the mass of the motor and the internal resistance of the winding determine the time-constant.

这种相互作用的结果是另一种指数瞬态过程,其中电机的质量和绕组的内阻决定了时间常数

6.When this transient finishes, neither speed, torque, voltage or current changes in the device any more. This means that the torque on mass must be 0, but that implies that the torque generated by the torque source must be equal to the torque consumed by the friction. It also means that the generator voltage must be high enough that the voltage drop on Rm (which determines the current through the motor) is just enough to generate that torque.

当这种瞬态过程结束时,设备中的速度、扭矩、电压或电流都不再发生变化。这意味着质量上的扭矩必须为0,但这意味着扭矩源产生的扭矩必须等于被摩擦力消耗的扭矩。这也意味着发电机的电压必须足够高,以至于 Rm上的电压降( (这决定了通过电机的电流)是刚好够用来产生扭矩.

从这个曲折的过程中,我们可以得出以下结论:

- Dealing with electro-mechanical systems, like a motor involves dealing with both electrical and mechanical aspects of it

- 处理机电系统,比如电机,会同时涉及到电气和机械方面的问题

- Some time-constants in the system are defined by purely mechanical or electrical components, however some could be determined by an interaction between the two

- 系统中的一些时间常数是由纯机械或电子元件定义的,然而,一些时间常数可以由两者之间的相互作用来确定

- Conversion equations and controlled-sources are important tools to describe relationships between electrical and mechanical quantities

- 转换方程和受控源是描述电气量和机械量之间关系的重要工具

- Combined systems are a pain in the rear to deal with

- 组合系统是后面处理的一个难题

So is there a better way? We’ll explore that in the next chapter

那么有没有更好的方法呢? 我们将在下一章探讨

5.Electrical Equivalent Circuits

电气等效电路

By now you probably have seen quite a few parallels between the ways we describe mechanical and electrical systems. Let’s imagine the following: we want to construct an electrical circuit that is a model of the mechanical circuit we would like to analyze! We want to do it so, that all the measurements and calculations we do in the electrical domain are immediately applicable to the mechanical equivalent.

到目前为止,你已经看到了我们描述的机械系统和电子系统有很多的相似之处。让我们想象一下: 我们想要构造一个电路,这是一个我们想要分析的机械电路的模型!我们希望这样做,这样我们在电子领域做的所有测量和计算,都能立即适用于机械等效系统。

The first order of business: how do we map our measureable quantities – torques and speeds – to voltages and currents? The natural mapping comes from the circuit laws. Once again, they are:

第一项业务: 我们如何将我们可测量的数量——转矩和速度——映射到电压和电流?当然映射来自于电路定律。再来一次,他们是:

1: For any node in the system the sum of the torque through all connecting elements to that node is 0.

1: 对于系统中的任何节点,通过所有连接单元到该节点的扭矩之和为0。

2: For any loop in the system the sum of the speed-differences on all the elements making that loop is 0.

2: 对于系统中的任何一个循环,构成该循环的所有元件的速度差之和为0。

The first law is similar to Kirchhoff’s current law: at any node in an electrical circuit, the sum of currents flowing into and out of that node is 0.

第一定律类似于基尔霍夫电流定律: 在电路的任何节点上,流入和流出该节点的电流之和为0。

The second law is the equivalent of Kirchhoff’s voltage law: the directed sum of the potential differences (voltage) around any closed circuit is zero.

第二定律等价于基尔霍夫电压定律: 任何闭合电路周围的电势差(电压)的有向和为零。

So, the natural mapping of these parameters is to represent torque with current and speed with voltage.

因此,这些参数的自然映射是用电流表示扭矩,电压表示速度。

We have to come up with ratios between torque and current and speed and voltage. Since we’re building only electrical models that make it easy to us to make calculations and predictions about mechanical systems, this factor can be anything convenient. We can say that 1A of current represents 1Nm of torque, but we could just as well as say that 1mA of current represents 1 oz” of torque, it doesn’t matter. Same goes for voltages and speeds. The only thing that matters is that we choose one conversion and we stick to it.

我们必须找出扭矩、电流、速度和电压之间的比率系数。由于我们只是建立电子模型,使我们很容易对机械系统进行计算和预测,这个因素可以是任何方便的。我们可以说1A 的电流代表1Nm 的扭矩,但我们也可以说1mA 的电流代表1盎司的扭矩,这无关紧要。电压和速度也是如此。唯一重要的是,我们选择其中一个转换,并坚持下去。

In the following I will use the mapping that 1A current represents 1Nm of torque and 1V voltage represents 1rad/s speed, but as I said before, this is arbitrary.

在下面我将使用1A 电流代表1Nm 的扭矩和1V 电压代表1rad/s 的速度的映射,但是正如我之前所说的,这是任意的。

Components

组件

The next order of business is to come up with electrical components that can be substituted for our mechanical ones. For this, we’ll look at the characteristic equations.

下一件事情是提出可以替代我们机械部件的电子部件。为此,我们来看一下特征方程。

DRAG

牵引力

Drag has a very simple one:

牵引力很简单:

T = d*s

We know now, that will represent torque with current and speed with voltage, so our electrical equivalent should have a characteristic equation of the following form:

我们现在知道,这将代表扭矩与电流和速度与电压,所以我们的电当量应该有一个特征方程的形式如下:

I = d*V

注释:U->I,S->V

This is a resistor, with a resistance of ‘d’.

这是一个电阻器,电阻为 d。

KINETIC FRICTION

动摩擦

Friction is a little more complex, being a non-linear component. The original characteristic equation was:

摩擦力是一个非线性部件,因此稍微复杂一些。最初的特征方程是:

T = sign(s) * f

Doing the replacement we get:

做我们得到的替换:

I = sign(V) * f

This can be modeled with a controlled current source, that changes direction depending on the voltage applied to it. And just as in the mechanical version, this model can be simplified to a constant current source if you assume that voltage never changes polarity.

这可以用一个受控电流源来模拟,这个电流源会根据施加在它上面的电压改变方向。就像在机械模型中一样,如果你假设电压永远不会改变极性,那么这个模型可以简化为恒流源。

STATIC FRICTION

静摩擦

Static friction is even more troublesome. The characteristic equation is not only non-linear but hysteretic as well:

静摩擦更麻烦,特征方程不仅是非线性的,而且是滞后的:

s = 0 if abs(T) < d; T = 0 if s > 0

只有在速度差为0的时候,静摩擦才会产生一个扭矩

After replacement we get:

更换之后,我们得到:

V = 0 if abs(I) < d; I = 0 if V > 0

This is either a short or an open circuit depending on the state of the element.

它是短路或开路取决于元件的状态。

MASS

质量

Masses equation was the following:

质量方程如下:

T = J * (ds/dt)

After replacement we get:

更换之后,我们得到:

I = J * (dV/dt)

This is what a capacitor does, if it has a capacitance of ‘J’.

这就是电容器的作用,它的电容值是“ J”的话。

SPRING

弹簧

It is probably not a big surprise after all this that springs can be represented by inductors with an inductance of ‘1/K’, bacuse

这并不意外,毕竟所有这一切,弹簧可以表现为电感量的’1/K’ 的电感,因为

dT/dt = K * s

becomes

变成

dI/dt = K * V

TORQUE SOURCE

扭矩源

Sources are almost trivial to convert: since torque becomes current, torque sources become current sources.

转换源的难度几乎是微不足道的: 因为扭矩源成为电流源。

SPEED SOURCE

速度源

Similarly, speed sources are converted into voltage sources.

类似地,速度源被转换成电压源。

SUMMARY

总结

To summarize, during the conversion to an electrical circuit, the following replacements are made:

总而言之,在转换成电路的过程中,需要进行以下更换:

| 原值(Original) | 转换值(Converted) |

| 扭矩(Torque) | 电流(Current) |

| 速度(Speed) | 电压 (Voltage ) |

| 阻力(Drag ) | 电阻器(R = d) |

| 动力摩擦(Kinetic Friction ) | 非线性,受控电流源(Non-linear, controlled current-source ) |

| 静态摩擦(tatic Friction) | 迟滞开路或短路(Hysteretic open or short circuit ) |

| 质量 (Mass ) | 电容器 (capacity C = J) |

| 弹簧(Spring ) | 电感器(inductance L = 1/K) |

| 扭矩源(Torque Source ) | 电流源(Current Source ) |

| 速度源 (Speed Source ) | 电压源 (Voltage Source ) |

8.Another look at the DC motor

再看看直流电动机

As our first example, let’s continue where we left off with modeling our old DC motor:

作为我们的第一个例子,让我们继续讨论建模的旧直流电动机:

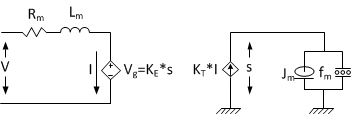

Now, let’s use our newly acquired knowledge and replace the left-side with their corresponding electrical symbols:

现在,让我们使用我们新获得的知识,用相应的电子符号代替左侧:

As you can see, I’ve replaced the speed with voltage (Vs), all the components with their electrical equivalent and the mechanical ground with the electrical one. This latest step is not really relevant. In fact, when you replace the mechanical ground, you can replace it with any constant voltage node. Just make sure you keep some absolute and constant reference around for the mechanical portion.

正如你所看到的,我已经用电压(Vs)代替了速度,所有的元件都用它们的电等效物,机械接地用电的。这个最新的步骤其实并不重要。事实上,当你更换机械接地时,你可以用任何恒压节点来替换它。只要确保你与周围的机械部分保持绝对和恒定的参考。

You now have a completely electrical circuit, that you can reason about using all the familiar techniques of circuit analysis. I’ll do just that, but first, let’s put some numbers in place! For this example, I’ll take the 1024-003s motor from Faulhaber because it has a fairly detailed datasheet. From that:

现在你有了一个完整的电路,你可以用所有熟悉的电路分析技术,来推理它。我会这样做,但首先,让我们把一些数字搞到位!对于这个例子,我将以 Faulhaber 的1024-003s 马达为例,因为它有一个相当详细的数据表。如下:

Rm = 2.3 Ω

Lm = 26 µH

KE = 0.215 mV/rpm = 0.002 V/(rad/s)

KT = 2.05 mNm/A = 0.002 Nm/A

Jm = 0.12 gcm2 = 0.11 * 10-6 Nm2

Fm = 0.03 mNm = 0.03 * 10-3 Nm

If we represent 1Nm torque with 1A of current and 1rad/s of speed with 1V of voltage, we get the following electrical equivalent:

如果我们用1A 的电流和1rad/s 的速度和1V 的电压来表示1Nm 的扭矩,我们得到下面的电气量:

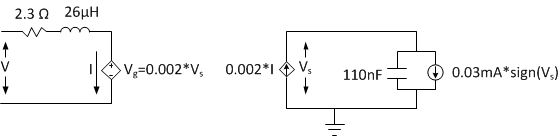

This is a circuit that you can put in a circuit simulator (if you do, be careful about the polarities of the sources!) and plot the frequency response for example (here I plot the generator voltage):

因为这是一个电路,所以你可以把它放在电路模拟器中(如果你这样做,要小心源的极性!)并绘制频率响应,例如(这里我绘制发电机电压) :

You see the expected low-pass characteristics, with two corner-frequencies. One at around 3Hz, the other at around 20kHz. This is very similar to what we’ve seen with our simple motor modeling exercise. Of course the values are different as we’re dealing here with a different motor.

你可以看到预期的低通特性,有两个转折频率。一个在3HZ左右,另一个在20KHZ左右。这与我们在简单的运动建模练习中看到的非常相似。当然值是不同的,因为我们要处理的是一个不同的电机。

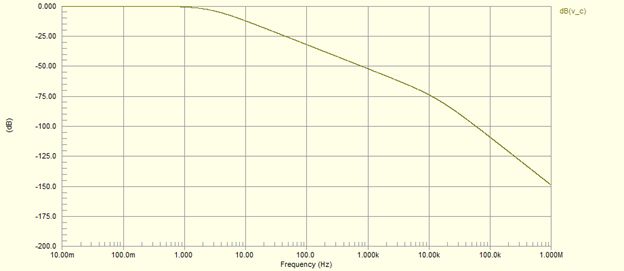

The interesting thing in this model however, is that it preserves the mechanical quantities as well. For example, in the following I’ll put a 3V pulse for 1s on the motor and plot the voltage across the capacitor:

在这个模型中有趣的是,它也保留了力学量。例如,在下面的例子中,我将在电机上放置一个3 v 的脉冲,持续时间为1 s,并绘制电容器上的电压:

Now, we know that we modeled speed with voltage, so we’re in fact looking at a speed-over-time graph here. It shows that when the voltage is turned on, it takes some time – around 250ms – for the motor to reach the target speed. When the transient is finally over, we measure 1.48kV on the capacitor. (Don’t be afraid of the big numbers, these are not real voltages, just equivalent numbers.) We’ve represented 1rad/s speed with 1V, so it must be 1480 rad/s speed. Converting it to rpm, we get 14132. This is close to the 13800 rpm value, specified in the datasheet. The difference is probably in the way we model our losses versus how they actually are in the motor. 3% accuracy is pretty good for such a simple model.

现在,我们知道我们用电压来模拟速度,所以我们实际上在看一个速度-时间曲线图。结果表明,当电压被接入时,电机需要一段时间——大约250ms——才能达到目标速度。当暂态过程结束时,我们测得电容器两端的电压为1.48 kV 。(不要害怕这一巨大的数字,这些不是真正的电压,只是等价的数字。)我们已经用1V 表示了1rad/s 的速度,所以它是1480 rad/s 的速度。把它转换成 rpm,我们就得到了14132。这接近于数据表中指定的13800 rpm 。区别可能在于我们模拟损失的方式以及它们在发动机中的实际情况。对于这样一个简单的模型来说,3% 的准确率是相当不错的。

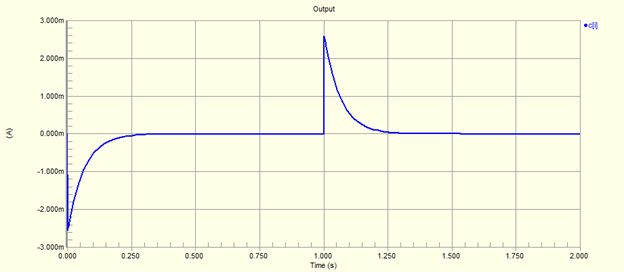

We can also plot the current through the capacitor:

我们还可以绘制通过电容器的电流:

Here you see that the torque decreases to 0 (in fact the only torque converted on the motor is used up by friction) after the initial transient. The peak current is at 2.5mA. This corresponds to 2.5mNm torque on the rotating disc. There’s a small amount of torque that’s consumed by the fiction so the motor needs to output a little more than that.

在这里你可以看到,转矩降低到0(事实上,唯一转化的转矩是用于电动机的摩擦)后,初始瞬态。峰值电流为2.5毫安。这相当于旋转圆盘上的2.5 mNm 扭矩。有一个小数额的扭矩,是消耗的部分,所以电机需要输出地方的扭矩比它多一点。

While this example is not terribly enlightening unless our plan is to use the motor without any load, but shows that we can directly obtain mechanical properties from the equivalent electrical circuit.

虽然这个例子不是很有启发性,除非我们计划在没有任何负载的情况下使用电动机,但它表明我们可以直接从等效电路获得机械性能。

The last thing I would like to point out is this: since the we’ve preserved the topology of the mechanical side of the system, we still have a representation for the output shaft of the motor. So, if we want to now tie a load to the motor (let’s say a large wheel with some friction), we can do that. All we need to do is extend our mechanical model with the new components:

最后我想指出的是: 因为我们保留了系统机械部分的拓扑结构,我们仍可以对电机输出轴做出表示。所以,如果我们现在想把一个负载加在在马达上(比如说一个摩擦力很大的轮子) ,我们可以这样做。我们需要做的就是用新的组件扩展我们的机械模型:

Here Jw and fw are the inertia and the friction of the wheel respectively. Now, we can re-draw our electrical equivalent:

这里 Jw 和 fw 分别是车轮的惯性和摩擦力。现在,我们可以重新绘制我们的等效电路:

We can use this new model to reason about the changed circuit. For example, we see that Jm and Jw are in parallel, so their capacitance will add together. This means that the lower corner-frequency in our frequency response plot (which is determined by the capacitance and Rm) will move to a lower frequency. In other words, if you add a wheel to a motor, it will become more sluggish to respond to voltage changes, which is not that surprising. But now we also see that we can’t move that corner-frequency higher – at least not with passive circuitry. For that we would need to either reduce the capacitance – which has a minimum set by the inertia of the rotor – or the series resistance – which also has a minimum set by the internal resistance of the coils. Our only chance to make our system respond faster is to use active elements, in other words, introducing a control mechanism.

我们可以用这个新的模型来推断电路的变化。例如,我们看到 Jm 和 Jw 是并行的,因此它们的电容将相加。这意味着在我们的频率响应图中较低的转折频率(由电容和 Rm 决定)将移动更低频率。换句话说,如果你在发动机上加一个轮子,电机对电压变化的反应会变得更迟钝,这并不奇怪。但现在我们也看到,我们不能把转折频率变得更高-至少使用无源电路是不行的。为此,我们需要同时降低电容——它是由转子的惯性设定一个最小值——以及减少串联的电阻——它==是由线圈的内阻设定一个最小值。我们唯一能使系统响应更快的机会是使用活动元素,换句话说,引入一种控制机制。