5 机器人正动力学代码及验证

得到了机器人的逆动力学方程后,为了得到最终动力学普遍方程的矩阵形式,需要提取求解惯性矩阵、刚度矩阵、科氏力等速度相关矩阵。

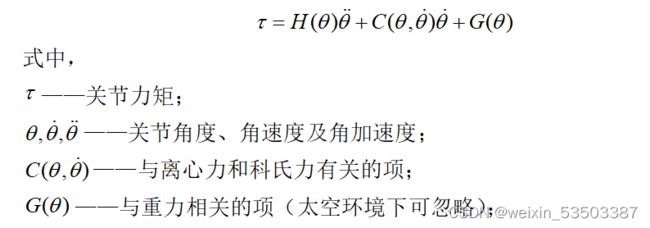

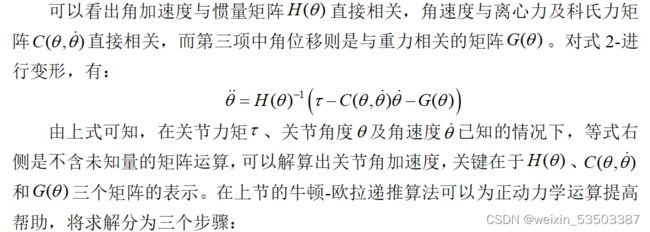

采用基于关节空间惯量矩阵的方法进行正动力学求解,基于系统动力学普遍方程式的特点,根据相关条件求出各系数矩阵,进而得出关节加速度。机器人动力学模型矩阵形式表示的一般方程如下:

代码1:逆动力学计算(不考虑重力情况)

%% 平面3dof简化模型(逆动力学)

function tol=equation3(dq1,dq2,dq3,ddq1,ddq2,ddq3)

% syms q1 q2 q3 l1 l2 l3 m1 m2 m3;

syms q1 q2 q3 ;

%% 参数初始化

R01=[cos(q1) -sin(q1) 0;

sin(q1) cos(q1) 0;

0 0 1];

R12=[cos(q2) -sin(q2) 0;

sin(q2) cos(q2) 0;

0 0 1];

R23=[cos(q3) -sin(q3) 0;

sin(q3) cos(q3) 0;

0 0 1];

R34=[1 0 0;

0 1 0;

0 0 1];

R10 =R01.';

R21 =R12.';

R32 =R23.';

R43=R34.';

l1=0.5;l2=0.5;l3=0.5;

m1=1.8751381;m2=1.8751381;m3=1.8751381;

%连杆坐标系位置

p10=[0; 0; 0];p21=[l1; 0; 0];p32=[l2;0;0];p43=[l3;0;0];

% 每个连杆质心的位置矢量

pc11 = 0.5 * p21; pc22 = 0.5 * p32; pc33=0.5*p43;

% 惯性张量

I1=[ 0.00058598 0 0;

0 0.03935837 0;

0 0 0.03935837];

I2=[ 0.00058598 0 0;

0 0.03935837 0;

0 0 0.03935837];

I3=[ 0.00058598 0 0;

0 0.03935837 0;

0 0 0.03935837];

% 连杆间角速度和角加速度

w00 = [0; 0; 0]; v00 = [0; 0; 0]; w00d = [0; 0; 0]; v00d = [0; 0; 0];%base_link的各项初始值

z = [0; 0; 1];

% 末端执行器没有力

f44 = [0; 0; 0]; n44= [0; 0; 0];

%% 建立动力学方程

%i=0

w11 = R10*w00 + dq1*z;

w11d = R10*w00d + cross(R10*w00, z*dq1) + ddq1*z;

v11d = R10*(cross(w00d, p10) + cross(w00, cross(w00, p10)) + v00d);

vc11d = cross(w11d, pc11) + cross(w11, cross(w11, pc11)) + v11d;

F11 = m1*vc11d;

N11 = I1*w11d + cross(w11, I1*w11);

% i = 1

w22 = R21*w11 + dq2*z;

w22d = R21*w11d + cross(R21*w11, z*dq2) + ddq2*z;

v22d = R21*(cross(w11d, p21) + cross(w11, cross(w11, p21)) + v11d);

vc22d = cross(w22d, pc22) + cross(w22, cross(w22, pc22)) + v22d;

F22 = m2*vc22d;

N22 = I2*w22d + cross(w22, I2*w22);

% i = 2

w33 = R32*w22 + dq3*z;

w33d = R32*w22d + cross(R32*w22, z*dq3) + ddq3*z;

v33d = R32*(cross(w22d, p32) + cross(w22, cross(w22, p32)) + v22d);

vc33d = cross(w33d, pc33) + cross(w33, cross(w33, pc33)) + v33d;

F33 = m3*vc33d;

N33 = I3*w33d + cross(w33, I3*w33);

%% Inward iterations: i: 6->1

% i = 3

f33 = R34*f44 + F33;

n33 = N33 + R34*n44 + cross(pc33, F33) + cross(p43, R34*f44);

tau(3) = n33(3);

% i=2

f22 = R23*f33 + F22;

n22 = N22 + R23*n33 + cross(pc22, F22) + cross(p32, R23*f33);

tau(2) = n22(3);

% i =1

f11 = R12*f22 + F11;

n11 = N11 + R12*n22 + cross(pc11, F11) + cross(p21, R12*f22);

tau(1) = n11(3);

tol(1)=simplify(tau(1));

tol(2)=simplify(tau(2));

tol(3)=simplify(tau(3));

代码2:系数提取

%% 计算M阵和C阵系数(逆动力学)

function [M,C]=call_dynamic()

% syms l1 l2 l3 m1 m2 m3 ;

syms dq1 dq2 dq3 ;

m11=equation3(0,0,0,1,0,0);

M11=vpa(m11(1),5);

M21=vpa(m11(2),5);

M31=vpa(m11(3),5);

m12=equation3(0,0,0,0,1,0);

M12=vpa(m12(1),5);

M22=vpa(m12(2),5);

M32=vpa(m12(3),5);

m13=equation3(0,0,0,0,0,1);

M13=vpa(m13(1),5);

M23=vpa(m13(2),5);

M33=vpa(m13(3),5);

c1=equation3(dq1,dq2,dq3,0,0,0);

C1=vpa(c1(1),5);

C2=vpa(c1(2),5);

C3=vpa(c1(3),5);

M=[M11,M12,M13;

M21,M22,M23;

M31,M32,M33];

C=[C1;C2;C3];

代码3:系数整理

[M,C]=call_dynamic();

M11=vpa(simplify(M(1,1)),6);

M12=vpa(simplify(M(1,2)),6);

M13=vpa(simplify(M(1,3)),6);

M21=vpa(simplify(M(2,1)),6);

M22=vpa(simplify(M(2,2)),6);

M23=vpa(simplify(M(2,3)),6);

M31=vpa(simplify(M(3,1)),6);

M32=vpa(simplify(M(3,2)),6);

M33=vpa(simplify(M(3,3)),6);

C1=vpa(simplify(C(1)),6);

C2=vpa(simplify(C(2)),6);

C3=vpa(simplify(C(3)),6);

代码4:写入S函数

%% 平面3dof动力学模型(正动力学)

function [sys,x0,str,ts,simStateCompliance] = plant(t,x,u,flag)

switch flag,

case 0,

[sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes;

case 1,

sys=mdlDerivatives(t,x,u);

case 2,

sys=mdlUpdate(t,x,u);

case 3,

sys=mdlOutputs(t,x,u);

case 4,

sys=mdlGetTimeOfNextVarHit(t,x,u);

case 9,

sys=mdlTerminate(t,x,u);

otherwise

DAStudio.error('Simulink:blocks:unhandledFlag', num2str(flag));

end

end

function [sys,x0,str,ts,simStateCompliance]=mdlInitializeSizes

sizes = simsizes;

sizes.NumContStates = 6;

sizes.NumDiscStates = 0;

sizes.NumOutputs = 6;

sizes.NumInputs = 3;

sizes.DirFeedthrough = 1;

sizes.NumSampleTimes = 1;

sys = simsizes(sizes);

% x0 = [0.1,0.1,0.1,0.1,0.1,0.1];

x0 = [0,0,0,0,0,0];

str = [];

ts = [0 0];

simStateCompliance = 'UnknownSimState';

% end mdlInitializeSizes

end

function sys=mdlDerivatives(t,x,u)

tol=[u(1);u(2);u(3)];

q1=x(1);

dq1=x(2);

q2=x(3);

dq2=x(4);

q3=x(5);

dq3=x(6);

D11=0.46878*cos(q2 + q3) + 1.4064*cos(q2) + 0.46878*cos(q3) + 1.876;

D12=0.23439*cos(q2 + q3) + 0.70318*cos(q2) + 0.46878*cos(q3) + 0.78189;

D13=0.23439*cos(q2 + q3) + 0.23439*cos(q3) + 0.15655;

D21=0.23439*cos(q2 + q3) + 0.70318*cos(q2) + 0.46878*cos(q3) + 0.78189;

D22=0.46878*cos(q3) + 0.78189;

D23=0.23439*cos(q3) + 0.15655;

D31=0.23439*cos(q2 + q3) + 0.23439*cos(q3) + 0.15655;

D32=0.23439*cos(q3) + 0.15655;

D33=0.15655;

M=[D11,D12,D13;

D21,D22,D23;

D31,D32,D33];

C1=- 0.70318*dq2^2*sin(q2) - 0.23439*dq3^2*sin(q3) - 0.23439*dq2^2*sin(q2 + q3) - 0.23439*dq3^2*sin(q2 + q3) - 1.4064*dq1*dq2*sin(q2) - 0.46878*dq1*dq3*sin(q3) - 0.46878*dq2*dq3*sin(q3) - 0.46878*dq1*dq2*sin(q2 + q3) - 0.46878*dq1*dq3*sin(q2 + q3) - 0.46878*dq2*dq3*sin(q2 + q3);

C2=0.70318*dq1^2*sin(q2) - 0.23439*dq3^2*sin(q3) + 0.23439*dq1^2*sin(q2 + q3) - 0.46878*dq1*dq3*sin(q3) - 0.46878*dq2*dq3*sin(q3);

C3=0.46878*sin(q3)*((dq1 + dq2)*(0.5*dq1 + 0.5*dq2) + 0.5*dq1^2*cos(q2)) + 0.23439*dq1^2*cos(q3)*sin(q2);

C=[C1;C2;C3];

S=M\(tol-C);

sys(1)=x(2);

sys(2)=S(1);

sys(3)=x(4);

sys(4)=S(2);

sys(5)=x(6);

sys(6)=S(3);

% end mdlDerivatives

end

function sys=mdlUpdate(t,x,u)

sys = [];

% end mdlUpdate

end

%

%

function sys=mdlOutputs(t,x,u)

sys(1)=x(1);

sys(2)=x(2);

sys(3)=x(3);

sys(4)=x(4);

sys(5)=x(5);

sys(6)=x(6);

end

function sys=mdlGetTimeOfNextVarHit(t,x,u)

sampleTime = 1; % Example, set the next hit to be one second later.

sys = t + sampleTime;

% end mdlGetTimeOfNextVarHit

end

%

%=============================================================================

% mdlTerminate

% Perform any end of simulation tasks.

%=============================================================================

%

function sys=mdlTerminate(t,x,u)

sys = [];

% end mdlTerminate

end

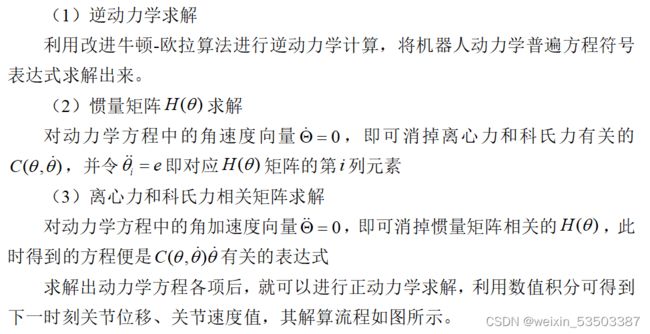

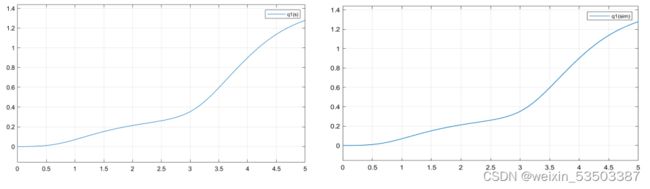

创建SIMULINK,进行正动力学仿真:

仿真时间5s,输入力矩为0.2sint 0.1sint 0.1sint

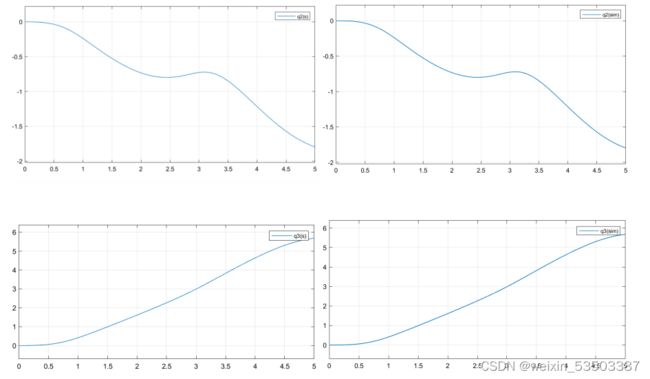

创建SIMSCAPE,进行仿真验证:

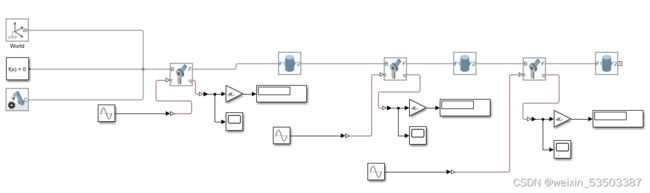

结果一致: