Batch Management

Agenda

1. The purpose Batch Management

2. The different terminologies in Batch management

3. Batch Management in different modules

4. Traceability with Batch

5. Notes

1. The purpose Batch Management

Product produced according to the Recipe and in one homogenous mixture which can not be reproduced

It is mainly used in

- Food product manufacturing

- Chemical manufacturing

- Process Industries.

2. The different terminologies in Batch management

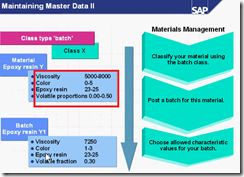

- Batch characteristics

It is the property of the batch which has to be attached to the batch.

- Batch class

Class is the carrier of characteristics.

Class will be attached with the material master.

- Production Date:-

Date when the product was produced.

- Expiry Date:-

Date beyond when the product can no longer be used

- Shelf life period:-

It is the duration of any product when product can be used.

- Recurring inspection:-

Inspecting the product at periodic interval to check its shelf life.

- Batch Status:-

Condition of the Batch usability will be known from the batch status.

- Batch Search Strategy:-

While issuing the goods for process order or production order, batch number of components can be searched through Batch search strategy.

- Condition Technique – (Condition Table):-

System searches the batch through predefine tables in a sequence which are known as condition table and Access sequence.

- Condition Technique – (Access Sequence):-

System searches the batch through predefine tables in a sequence which are known as condition table and Access sequence.

3. Batch Management in different modules

Configuration

3.1 Batch Management can be activated in three levels. They are

- Client Level

- Plant Level

- Material Level

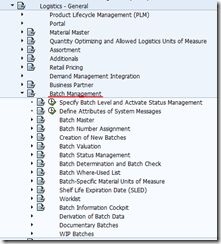

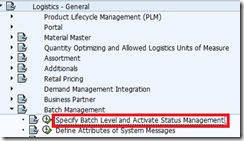

MENU PATH:-

IMG: Logistics General --> Batch Management --> Specify Batch Level and Activate Status Management

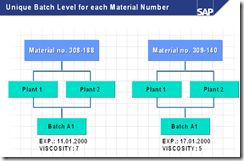

3.1.1 工厂级别

同一物料,同一批次可以在多个工厂中使用,但是在不同工厂中的特性值可以不同

3.1.2物料级别

同一物料,同一批次,在所有工厂中的特性值必须相同

3.1.3集团级别

一个批次号在整个集团是唯一的,只能分配一次,不能同时分配给其他物料

3.2 批次管理状态

3.2.1 Batch Activation in Material Master

Provision to activate batch management in material master is available in purchasing view and in work scheduling view.

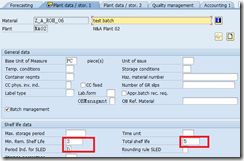

![]()

3.2.2 激活批次状态管理:限制和非限制状态

3.2.3 可以通过MSC2N 将批次限制,未来该批次就不可以使用

3.4 . 批次号码有生成方式:

3.4.1 . 批次号码可以手动输入:MSC1N

3.4.2. 可以系统自动分配:例如扣帐系自动分配

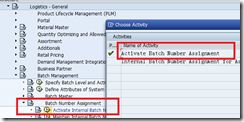

3.4.2.1激活自动分配号码(如果需要内部给号,需要进行激活)

3.4.2.2、系统移动时会自动产生批次,针对异动类型可以定义是否需要检查,以避免错误

(如下是设置画面,为了方便查看,贴图为中英文两个版本)

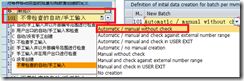

3.4.2.3 Define initial creation of Data for Batch master Transaction

可以针对Mat. Type设置Batch创建规则,这样就能实现成品101入库自动生成batch,而PO 101收料手动生成的效果

It should not be possible to assign a batch manually for finished products. The batch numbers should always be determined automatically by the system. To ensure they are determined automatically, choose the option “C - automatic/ No manual creation” for the material type

FERT.

3.5. Batch Valuation

Below is the Standard characteristics defined by SAP.

LOBM_VFDAT expiration date, shelf life

LOBM_VERAB availability date

LOBM_LFDAT delivery date

LOBM_RLZ required remaining shelf life of batch

LOBM_MENGE sortable quantity

LOBM_ZUSTD status of batches

LOBM_LVORM deletion flag

LOBM_BWTAR valuation type

LOBM_LGORT storage location

LOBM_QNDAT next batch check date

3.6 Batch 相关操作

3.6.1 Batch Class&Characteristics

3.6.1.1 Create characteristic -- CT04

3.6.1.2 Create Class (将特性归结到一起)-- CL02

Class type 分为两种:

023 批次层在物料层

022 批次层在工厂层

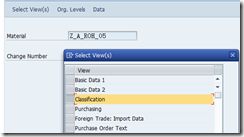

3.6.2 将Class(分类)指派给物料(物料用到批次时,不一定需要分类)

两种方式进行指派:

3.6.2.1 :建立料号时指派分类

如果分类中class type不是自己想要的,可以通过这种方式进行修改

放入类别名称:

3.6.2.2 :CL20N

可以新增或者修改

指派之后,在物料异动时,如果扣帐时没有提供特性值,会跳出特性值画面,如果特性值在扣帐时提供,系统会自动创建批次,批次会带出特性值

扣帐时已经找到特性值供应商,批次可以建立起来

当然也可以对某些关键特性设置必输项,并Error提示

CT04---

Customization:

查看库存时可以看到批次的详细信息

MSC3N 也可以看到详细的信息

3.6.3 . 物料主数据中限定的特性值,会限制未来物料异动的输入(异动时输入的值必须在物料主数据限定的范围)

3.7. 批次整合性

--货物移动都需要批次

--可以进行限制库存于非限制库存转移

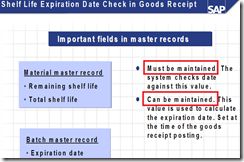

3.8. 剩余货架寿命

进料日期与有效期到期日所差的时间最短为最小剩余货架寿命才能扣帐

3.8.1 Master Data 维护

使用生命周期的情况下,最好使用批次,否则无法得知这批料何时到期

Max. storage period:主要是用做参考(This function helps you to monitor from disposal processing whether the maximum storage periods for wastes are being kept to.)

Time unit

Min. Rem. Shelf Life:最小剩余货架寿命(就是说仓库操作需要的最少时间)

Total shelf life :总寿命

Period Ind. for SLED: 货架寿命单位

Rounding rule SLED

Storage percentage

A 生产日期+总寿命-过账日期

B 剩余货架寿命

A >= B OK

3.8.2 检查到期日(OMJJ)

可以使用MCHA中的到期日或者收料日做先进先出的处理

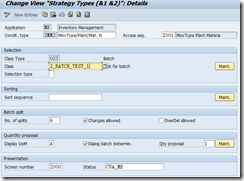

3. 9、Batch Determination and Batch Check

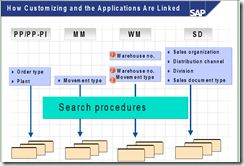

每个模块又相应的配置,配置起来比较复杂,原理跟Price Condition类似

不同的配置路径如下:

通过应用程序application得到查找程序search procedure

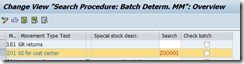

3.9.1 MM 移动类型

![]()

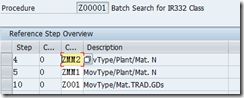

3.9.2. Search(上图Z0001)设定: Batch Search Procedure Definition

![]()

3.9.3 CTyp--Condition Type(上图ZMM2)设定: 找到策略类型(按顺序找,如果前面的策略类型没有再找后面的)

3.9.3.1 .Access Seq.--Z001,即路径:/Access Sequences,SAP通过Access Seq.找到Condition Table及字段

通过存取顺序得到表(多条)如果能读取到记录,就表示可以得到批次,如果读不到,就不会自动得到批次.

如何在Condition Table维护资料? -- MBC1

在操作MBC1时“Selection Criteria”务必要维护,否则Selection中即使放了Class系统也无法找到,因此就无法自动Select相应的batch

3.9.3.2 Selection -- 相当于filter,就是对找到的Batch筛选

3.9.3.3 Sorting

存取顺序(上图Sort Sequence)设定

3.9.3.4 Batch split

多个Batch对应一个Item(如Deli. Item)时所用

SELECT <Condition Filed> FROM <Condition Table> WHERE <Selection> SORT BY <Sorting>

3.9.3.5 领料操作 MB1A

发料输入*让系统自动找到批次

可以根据如下界面输入选择标准,在无法查找信息时进行策略分析

(通过选择标准按钮进入选择条件界面,Key 入选择条件则系统会带出符合条件的item供选择,策略分析可以看到是否正确batch determination找到对的item)

将排序顺序维护至策略类型(如果table之前维护时排序顺序没有维护,后续需要修改排序顺序)

5.Notes:

Activities in Batch Management

| Transaction |

Activity |

| CT04 |

建立特性 |

| CL02 |

创建类别 |

| CL20N |

指派给物料 |

| MB56 |

批次跟踪报表 |

| MSC3N |

Display Batch |

| MSC4N |

Display Changes |

| MM75 |

Display Archive |

| BMAA |

Overview of Archiving Runs |

| MBC3 |

Display Batch Search Strategy for Inventory Management |

| COB3 |

Display Batch Search Strategy for Production Order |

| COB3 |

Display Batch Search Strategy for Process Order |

| VCH3 |

Display Batch Search Strategy for Sales and Distribution |

| LS53 |

Display Batch Search Strategy for Warehouse Management |

| CT03 |

Display Characteristic |

| BMC3 |

Display Selection Class |

| CU72 |

Display Sort Rule |

| MB5C |

Pick-Up List |

| MB56 |

Display Batch Where-Used List |

| MB57 |

Compile Batch Where-Used File |

| BMBC |

Batch Information Cockpit |

| BMCC |

Integrity Check for Batch Classification |

| MB5M |

SLED List |

| QA07 |

Periodic Checks of Batches in QM |

| COEBR |

Batch Record |

| CO09 |

Availability Overview |

| MM03 |

Display Units of Measure for Material |

| MWB3 |

Display Standard Price |

| MWBC |

Consistency Check for Batch-Specific UoM |